3D printing machine forming platform lifting mechanism

A 3D printer, platform lifting technology, used in 3D object support structures, processing platforms/substrates, additive manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0045] Combine below Figure 1-20 To describe this embodiment,

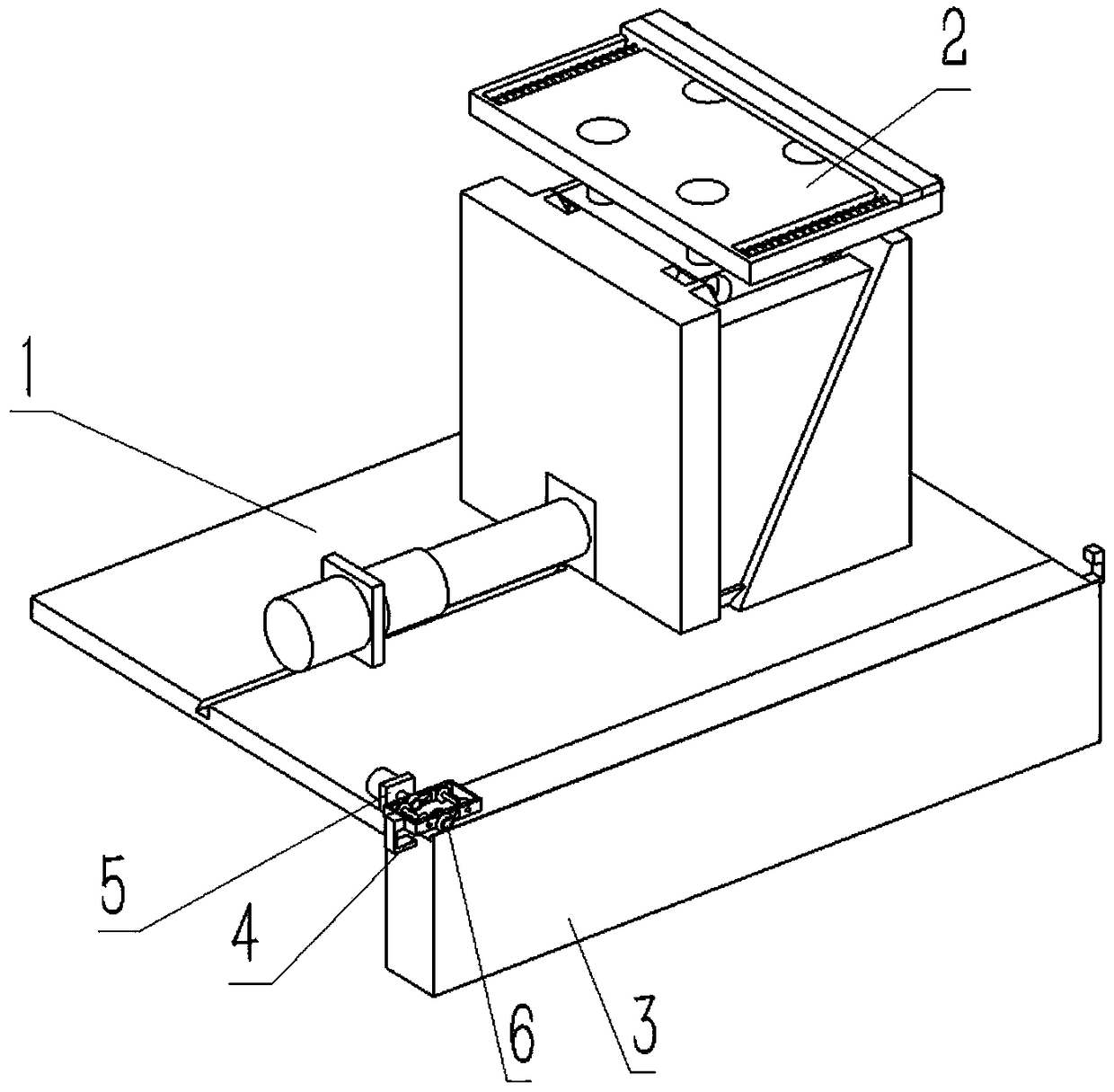

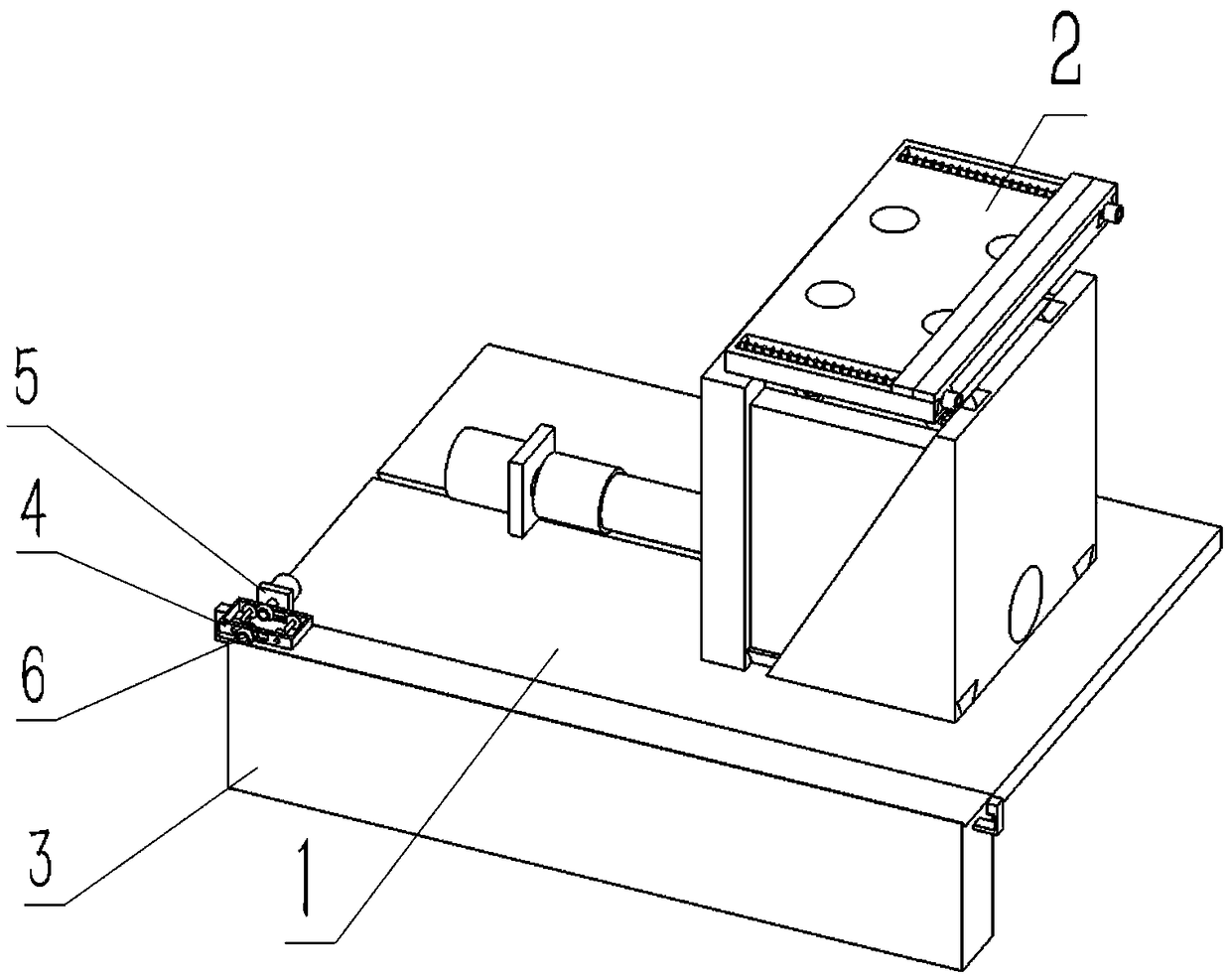

[0046] A 3D printer forming platform lifting mechanism, including a frame body 1, a lifting platform combination 2, an outer sliding frame 3, a reversing combination 4, a motor combination 5 and a transmission combination 6, and the lifting platform combination 2 is slidably connected to the frame body 1, the right end of the frame body 1 is slidably connected to the outer sliding frame 3, the reversing combination 4 is connected between the outer sliding frame 3 and the motor combination 5, and the left and right ends of the transmission combination 6 are respectively connected to the motor combination 5 and the outer Slide frame 3 engages the transmission.

specific Embodiment approach 2

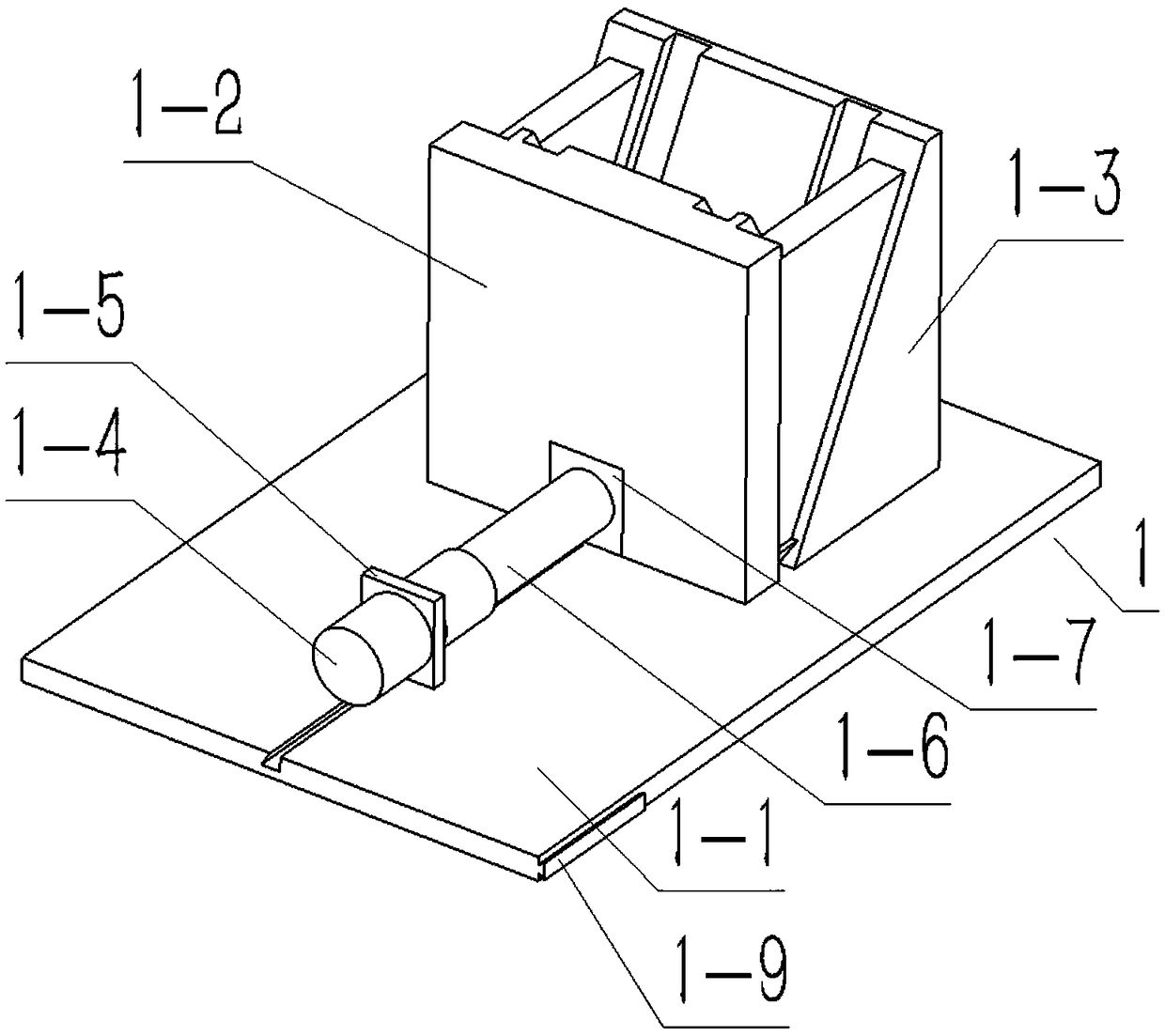

[0047] Combine below Figure 1-20 This embodiment will be described. This embodiment will further describe the first embodiment. The frame body 1 includes a bottom plate 1-1, a front frame body 1-2, a rear frame body 1-3, a motor 1-4, and a machine base 1- 5. Screw rod 1-6, positioning block 1-7, end 1-8 and trapezoidal slider 1-9, the upper end of the bottom plate 1-1 is provided with a trapezoidal groove 1-1-1, and the front frame body The lower end of 1-2 is connected to the base plate 1-1 by bolts, the lower end of the rear frame body 1-3 is in clearance fit with the upper end surface of the base plate 1-1, and the front frame body 1-2 is slidingly connected between the rear frame body 1-3 Inside, the motor 1-4 is fixed on the machine base 1-5 by bolts, the lower end of the machine base 1-5 is slidingly connected in the trapezoidal groove 1-1-1, and the drive shaft of the motor 1-4 is connected to the wire through a coupling. The front end of the rod 1-6, the positioning ...

specific Embodiment approach 3

[0050] Combine below Figure 1-20 Describe this embodiment, this embodiment will further explain the second embodiment, the lifting platform combination 2 includes a lower support platform 2-1, a runner 2-2, an upper support platform 2-3, bolts 2-4 and nuts 2 -5, four runners 2-2 are provided, and the four runners 2-2 are respectively rotated and connected to the four corners of the lower support platform 2-1, four nuts 2-5 are provided, and the upper support platform 2- 3 connected to the upper end of the lower support platform 2-1 by bolts 2-4;

[0051] The upper support platform 2-3 includes an upper support platform body 2-3-1, a slider 2-3-2, a lock nut 2-3-3 and a spring 2-3-4, and the upper support platform body 2 The upper end of -3-1 is provided with four threaded holes 2-3-1-1, and the left and right sides of the upper support platform body 2-3-1 are respectively provided with a trapezoidal groove 2-3-1-2, so A sliding post 2-3-1-3 is welded in the trapezoidal groo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap