Petroleum extraction device for molecular distillation

A molecular distillation and extraction device technology, which is applied in hydrocarbon distillation, petroleum industry, hydrocarbon oil distillation control/regulation, etc., can solve the problem of low precision, achieve the effect of accurate dosage, convenient use, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

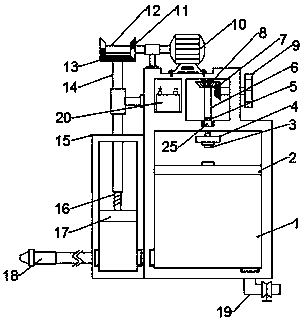

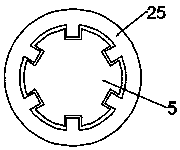

Embodiment 1

[0027] see figure 1 and 3 , in an embodiment of the present invention, a petroleum extraction device for molecular distillation, comprising a quantitative chamber 1, a push switch 3, a volume adjustment mechanism and a pumping mechanism; the side end of the quantitative chamber 1 is arranged on the pumping mechanism, and the pumping mechanism is connected to the Quantitative chamber 1 is connected, and the inner side of quantitative chamber 1 is slidingly provided with slide plate 2, and above the slide plate 2 is provided with push switch 3 fixed at the lower end of the volume adjustment mechanism. Petroleum rushes into quantitative chamber 1 to drive slide plate 2 to move upward, and the slide plate 2. The distance moved upwards determines the oil content in the quantitative chamber 1. The amount adjustment mechanism includes a mounting plate 4, a first threaded rod 5, a first threaded sleeve 6 and a turntable 9. The push switch 3 is fixed on the mounting plate 4 The lower ...

Embodiment 2

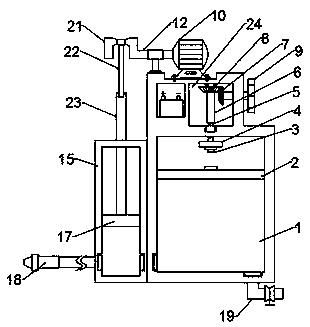

[0036] see figure 2 and 3 , in an embodiment of the present invention, a petroleum extraction device for molecular distillation, comprising a quantitative chamber 1, a push switch 3, a volume adjustment mechanism and a pumping mechanism; the side end of the quantitative chamber 1 is arranged on the pumping mechanism, and the pumping mechanism is connected to the Quantitative chamber 1 is connected, and the inner side of quantitative chamber 1 is slidingly provided with slide plate 2, and above the slide plate 2 is provided with push switch 3 fixed at the lower end of the volume adjustment mechanism. Petroleum rushes into quantitative chamber 1 to drive slide plate 2 to move upward, and the slide plate 2. The distance moved upwards determines the oil content in the quantitative chamber 1. The amount adjustment mechanism includes a mounting plate 4, a first threaded rod 5, a first threaded sleeve 6 and a turntable 9. The push switch 3 is fixed on the mounting plate 4 The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com