Fine carding machine for reducing cotton loss

A kind of carding machine, fine technology, applied in deburring device, textile and paper making, fiber processing, etc., can solve the problems of poor carding effect, cotton falling out, etc., to achieve enhanced processing effect, increased hardness, and reduced distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

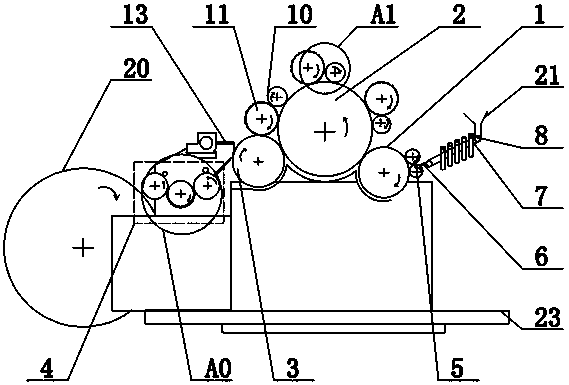

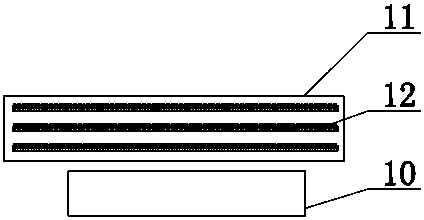

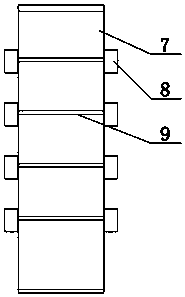

[0028] see Figure 1-5 , the present invention provides a technical solution: a fine carding machine capable of reducing cotton shedding, comprising a licker-in roller 1, a cylinder 2, a doffer 3, and a discharge assembly 4, which are arranged as two groups of feed rollers 5 near the licker-in roller 1, A feed tray 6 is arranged between the two sets of feed rollers 5, and the other end of the feed tray 6 is provided with a No. 1 conveyor belt 7, and the two sides of the No. 1 conveyor belt 7 are evenly and symmetrically fixedly connected with multiple sets of clamping rods 8, each group of clamping rods 8 is Both are provided with clamping holes, and a No. 1 pressure roller 9 is clamped and connected between each corresponding two groups of clamping rods 8 through the clamping holes, and a cylinder 2 is provided on the other side of the licker-in roller 1 relative to the feeding roller 5, Multiple sets of transfer rolls 10 and work rolls 11 are arranged around the cylinder 2, ...

Embodiment 2

[0038] see Figure 1-5 , the beneficial effect of the present invention is: this device has adopted the effective combination of No. When conveying, the first step of integration is carried out by multiple sets of No. 1 pressure rollers 9 on the upper part, so that it can be parallelized, and then the initially integrated loose cotton is sent to the doffer 3 feeding roller 5 through the feeding tray 6, so that the device can The later work is smooth; the work roll 11 in the carding structure is provided with a soft brush 12, so that the doffer 3 work roll 11 is rotating and the soft brush 12 can evenly align the alignment transfer roll 10 and the surface of the cylinder 2 Brush, because the pointing direction of the doffer 3 soft brush 12 is opposite to the rotation direction of the doffer 3 work roll 11, so the soft brush 12 will not affect the working effect of the cylinder 2, on the contrary, the doffer 3 soft brush 12 can rotate and carry the transfer roll 10 The cotton w...

Embodiment 3

[0040] see Figure 1-5 , the working principle of the present invention is: when in use, the staff will send the loose cotton from the feeding hopper 21, and then the loose cotton will be transported by the No. 1 conveyor belt 7. During the transport process, the No. 1 pressure roller 9 will press down the loose cotton , so that the surface becomes a flat surface, the No. 1 conveyor belt 7 transports the loose cotton to the feeding tray 6, and the feeding tray 6 will send the loose cotton to the mouth of the feeding roller 5, and the feeding roller 5 will roll it in;

[0041] After the feeding roller 5 draws in the loose cotton, the loose cotton is transported by the licker-in roller 1, and the loose cotton involved in the licker-in roller 1 is transported to the cylinder 2, and the carding operation is performed on the surface of the cylinder 2, and the cotton 2. While rotating, the work roll 11 and the transfer roll 10 will also rotate. When the transfer roll 10 rotates, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com