Special regularizing frame facilitating hoisting of climbing steel formwork

A climbing formwork and steel plate technology, which is applied in the field of construction, can solve the problems of affecting work efficiency, unusable overall climbing formwork, unfavorable steel formwork hoisting, etc., and achieves the effect of ensuring safety and convenient and orderly placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

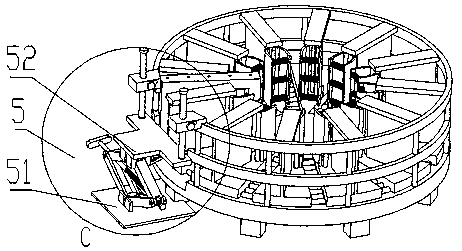

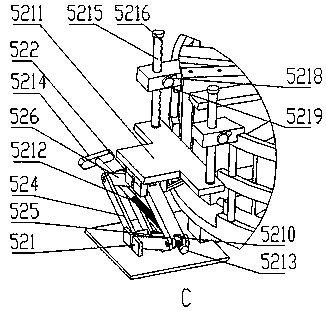

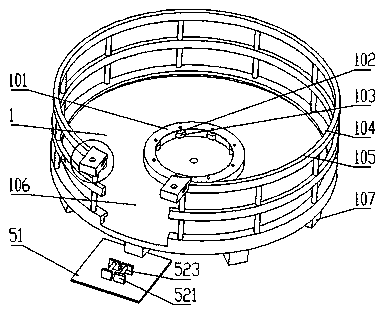

[0040] Specific implementation method: the turntable 4 can rotate under the drive of the motor 3. When the roller 402 is at the opening 106, the steel template 6 is manually placed on the roller 402. Since the roller 402 can rotate, the steel template 6 can be conveniently and labor-saving. The template 6 moves along the roller 402, and when it touches the arc-shaped plate 404, the arc-shaped plate 404 is pushed away, and the arc-shaped plate 404 clamps the steel template 6 under the action of the retaining column 408 and the spring 405, and the turntable 4 Rotate to place the next steel formwork 6, and the steel formwork 6 can be placed in sequence according to the installation order. For the stable rotation of the turntable 4, a small roller 103 is set. The line contact between the turntable 4 and the small roller 103 reduces the resistance. 406 further restricts the steel formwork 6 to prevent the clamping from being loose and the steel formwork 6 to be tilted to ensure safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com