Externally-hung assembly type enclosure wall based on side pin type wedge-shaped self-locking connection

A prefabricated and fenced technology, which is applied in the direction of fences, building types, buildings, etc., can solve the problems of high maintenance frequency and maintenance requirements, unfavorable structure durability, single form, etc., and achieve low construction requirements, efficient construction, easy processing and The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

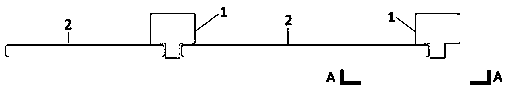

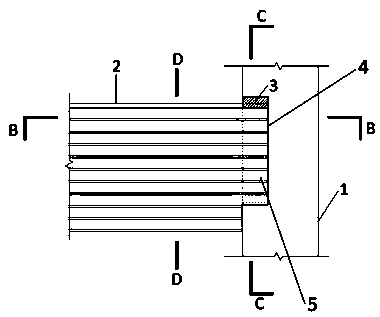

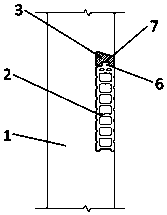

[0027] Such as Figure 1~4 As shown, a side pin type wedge-shaped self-locking connection external hanging assembled fence, including a prefabricated wall column 1, a groove 4 is formed on the side wall of the prefabricated wall column 1, and the groove 4 accommodates the prefabricated wall panel 2 A support head 5, a pin block 3 for fixing is arranged between the support head 5 and the groove 4, and a position-limiting structure is formed in the pin block 3.

[0028] The position-limiting structure includes that one side of the pin block 3 forms an inclined locking surface, and one side of the groove 4 is an inclined fixing surface, and the inclined locking surface and the inclined fixing surface engage with each other to prevent the pin block 3 from slipping out.

[0029] The side of the pin block 3 facing the support head 5 forms a pin block slot 7, and one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com