A snap-in raise drilling rig

A raise drilling rig, clip-on technology, applied in construction and other directions, can solve the problems of angle adjustment, wear, damage, etc., and achieve the effect of improving efficiency and floating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

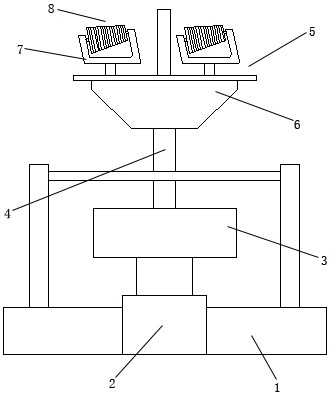

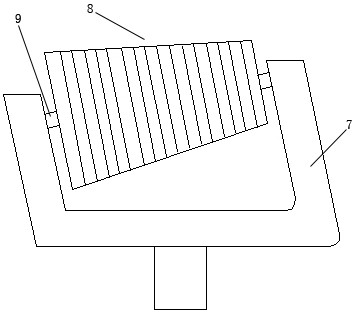

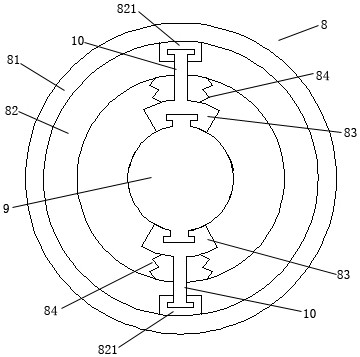

[0021] like Figures 1 to 6 As shown, a clamping type raise drilling machine includes a base support 1, a telescopic mechanism 2, a drill pipe 4, a drill bit 5, and a T-shaped telescopic rod 10; the telescopic mechanism 2 is installed on the base support 1; the described The drill rod 4 is installed on the upper end of the telescopic mechanism 2; the drill bit 5 is installed on the upper end of the drill rod 4; the drill bit 5 includes a cutter head 6, a knife seat 7, a drill bit 8, and a connecting shaft 9; The disk 6 is installed on the upper end of the drill rod 4; the upper end of the cutter head 6 is equipped with two tool holders 7; a connecting shaft 9 is installed in the described cutter holder 7; on axis 9; if image 3 and 4 As shown, it also includes a T-shaped telescopic rod 10; the drill bit 8 includes an outer ring sleeve 81, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com