Fully-mechanized roadway tunneling process based on robotized tunneling, supporting and anchoring combined unit

A combined unit and robot technology, applied in the direction of slitting machinery, bolt installation, mine roof support, etc., can solve the problems of low automation, low work safety, low tunneling efficiency, etc., and achieve high work efficiency and intelligent level High, good cutting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

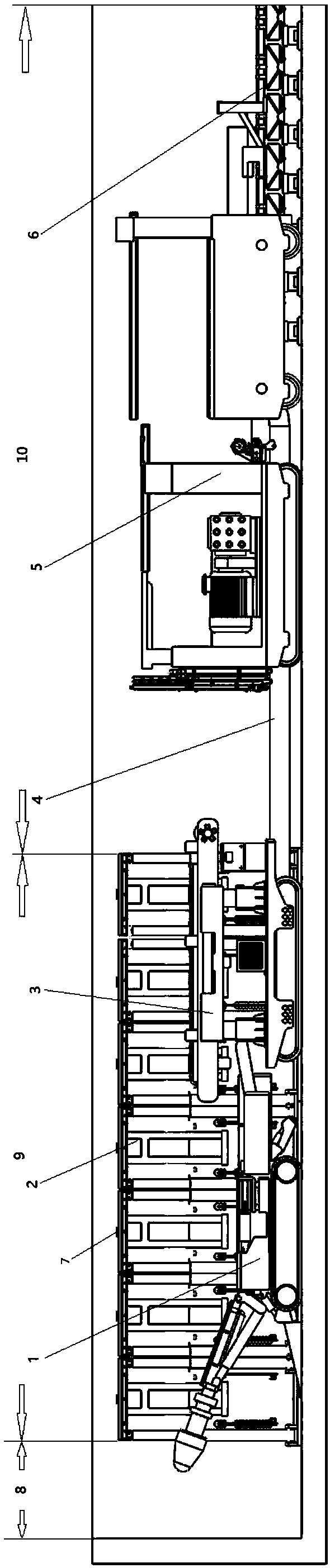

[0035] exist figure 1 In , the equipment layout of the fully mechanized roadway excavation process based on the robotized excavation, support and anchor unit is given. It can be seen from the figure that the process adopts unmanned intelligent autonomous roadheader 1, self-moving independent temporary support hydraulic pressure Support 2, autonomous positioning and mobile support transport vehicle 3, reloading machine 4, robotic drill and anchor vehicle 5 and belt conveyor 6. The entire excavation roadway can be divided into three areas: front-end excavation area 8 , temporary support area 9 , and permanent anchorage area 10 . Among them, the area where the unmanned intelligent autonomous roadheader 1 cuts the excavation is the front of the entire roadway, which is called the front-end excavation area 8; the position where the sel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap