Rotating type bottle drying machine and rotating type bottle drying system

A bottle drying machine and rotary technology, which is applied in dryers, non-progressive dryers, drying, etc., can solve the problems of poor effect, inability to remove, and poor dehydration effect of the bottle body, so as to achieve convenient use and low occupation Small space, fast and accurate removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

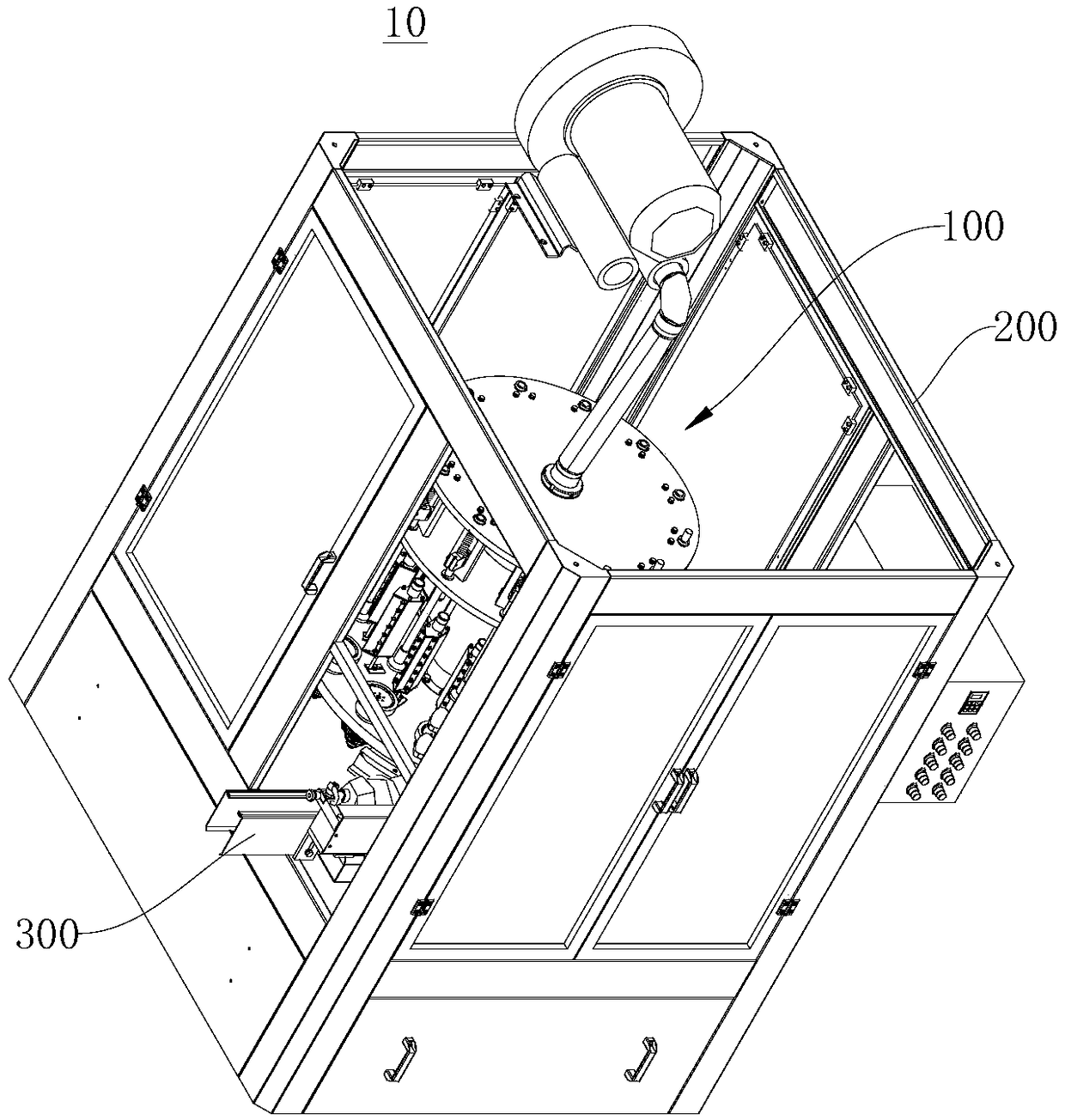

[0040] see Figure 1 to Figure 11 , This embodiment provides a rotary bottle drying machine 10, which is easy to use, can quickly and accurately remove residual water droplets on the bottle body, and occupies a small space.

[0041] It should be noted that the rotary bottle drying machine 10 provided in this embodiment is used to remove water droplets on the bottle body, which has met the labeling requirements on the bottle body. Compared with the existing bottle drying equipment, the rotary bottle drying machine 10 has the characteristics of convenient use, good water removal effect and small space occupation, and can also meet the requirements of modern automatic packaging, reduce labor intensity and labor cost.

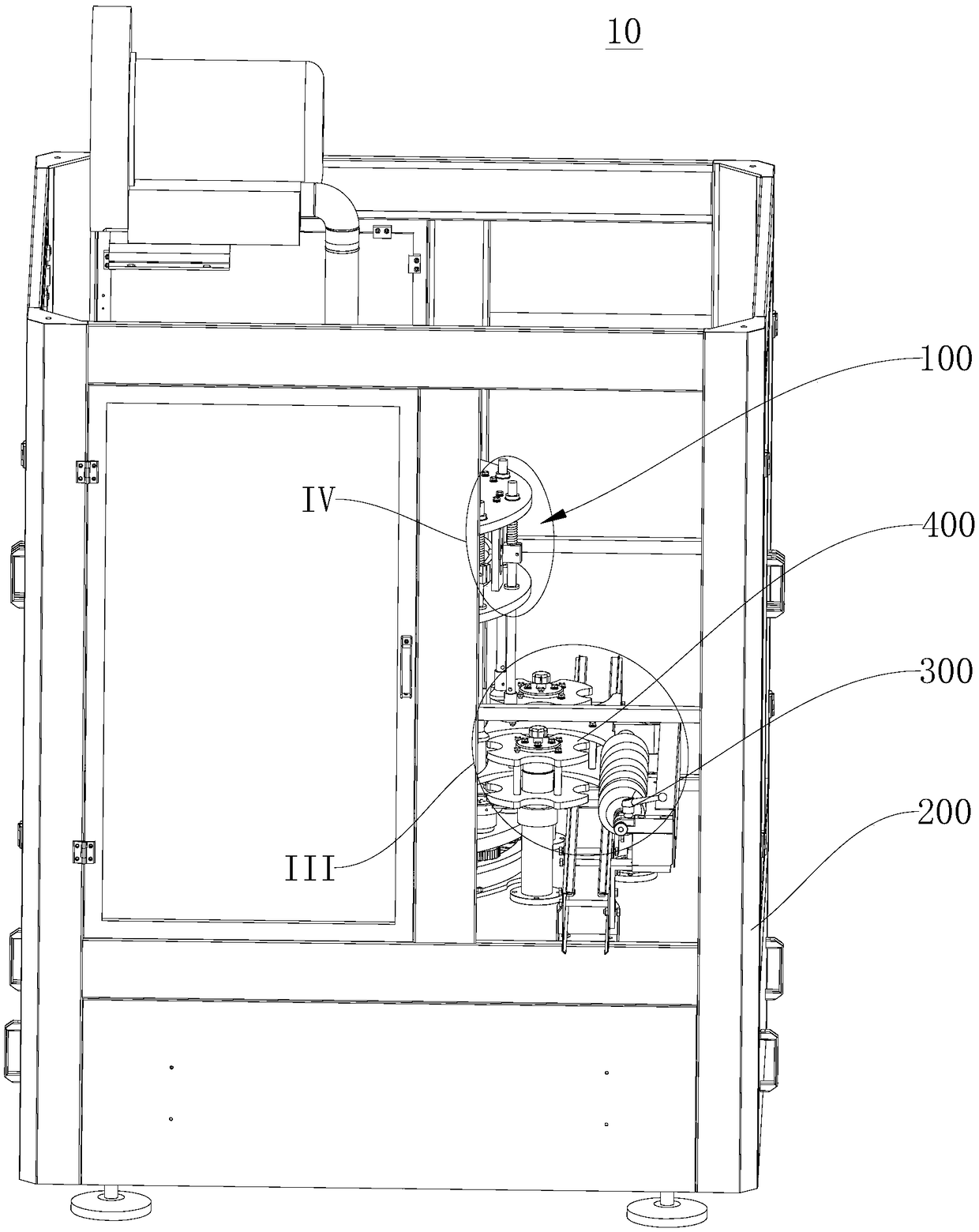

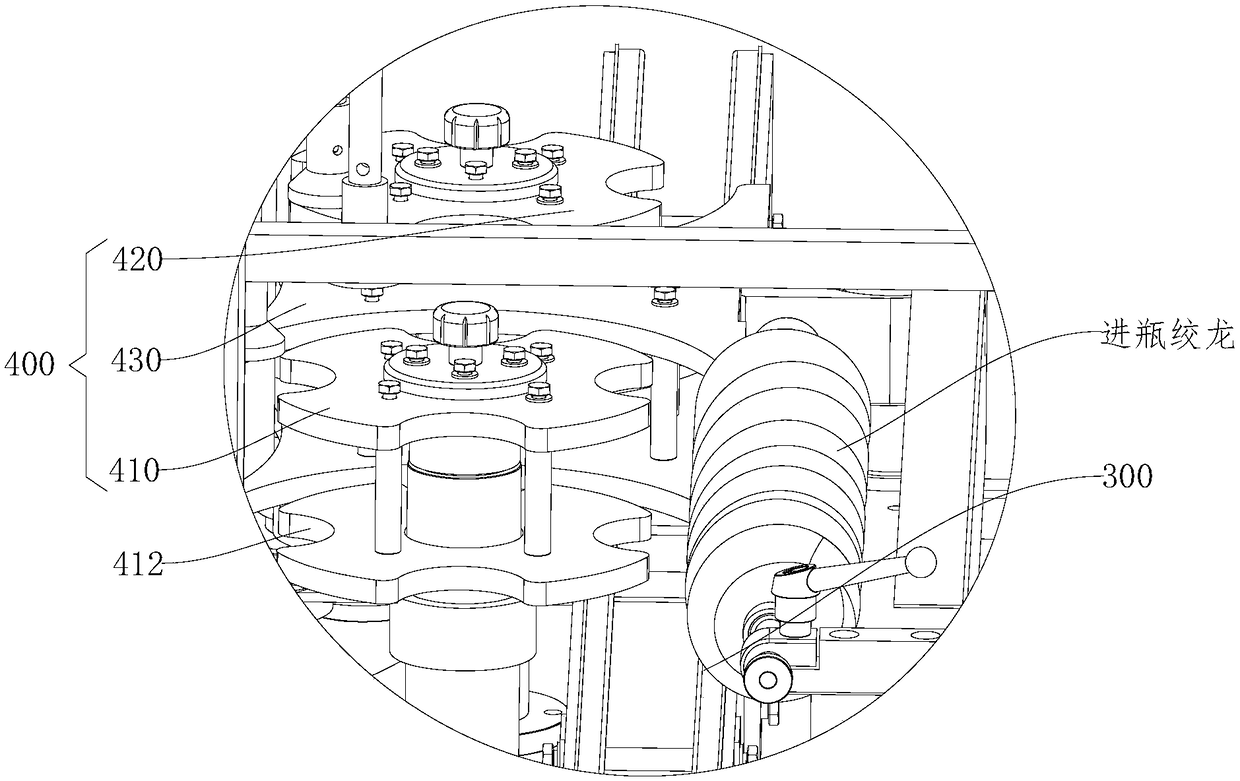

[0042] The rotary bottle drying machine 10 provided in this embodiment includes a frame 200, a conveying structure 300, a dial structure 400, a water receiving tray 500 and a rotating disk structure 100, and the water receiving tray 500, the conveying structure 300...

no. 2 example

[0065] see Figure 1 to Figure 11 , this embodiment provides a rotary bottle drying system, including a drive system and a rotary bottle drying machine 10 . The rotary bottle drying machine 10 includes a frame 200 , a conveying structure 300 , a dial structure 400 , a water tray 500 and a dial structure 100 , and the water tray 500 , the conveying structure 300 and the dial structure 400 are all mounted on the frame 200 . The turntable structure 100 includes a rotating shaft assembly 110, a rotating tray 120, a plurality of pressing bottle assemblies 130, a plurality of bottle holding assemblies 140 and an air knife assembly 150 with a plurality of air outlets. The rotating shaft assembly 110 is installed on the frame 200 and can be opposite to the When the frame 200 rotates, a plurality of air outlets of the air knife assembly 150 and a plurality of bottle holder assemblies 140 are arranged on the rotary tray 120 at intervals, and a plurality of bottle press assemblies 130 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com