Spherometer with adjustable measuring diameter, and measuring method for radius of curvature and offset

A technology of curvature radius and spherical diameter instrument, applied in the measurement of aspheric optical components and spherical surface, can solve the problems of complicated installation, influence of measurement accuracy, inability to accurately determine the center of the circle, etc., to improve processing efficiency, simple method, measurement fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

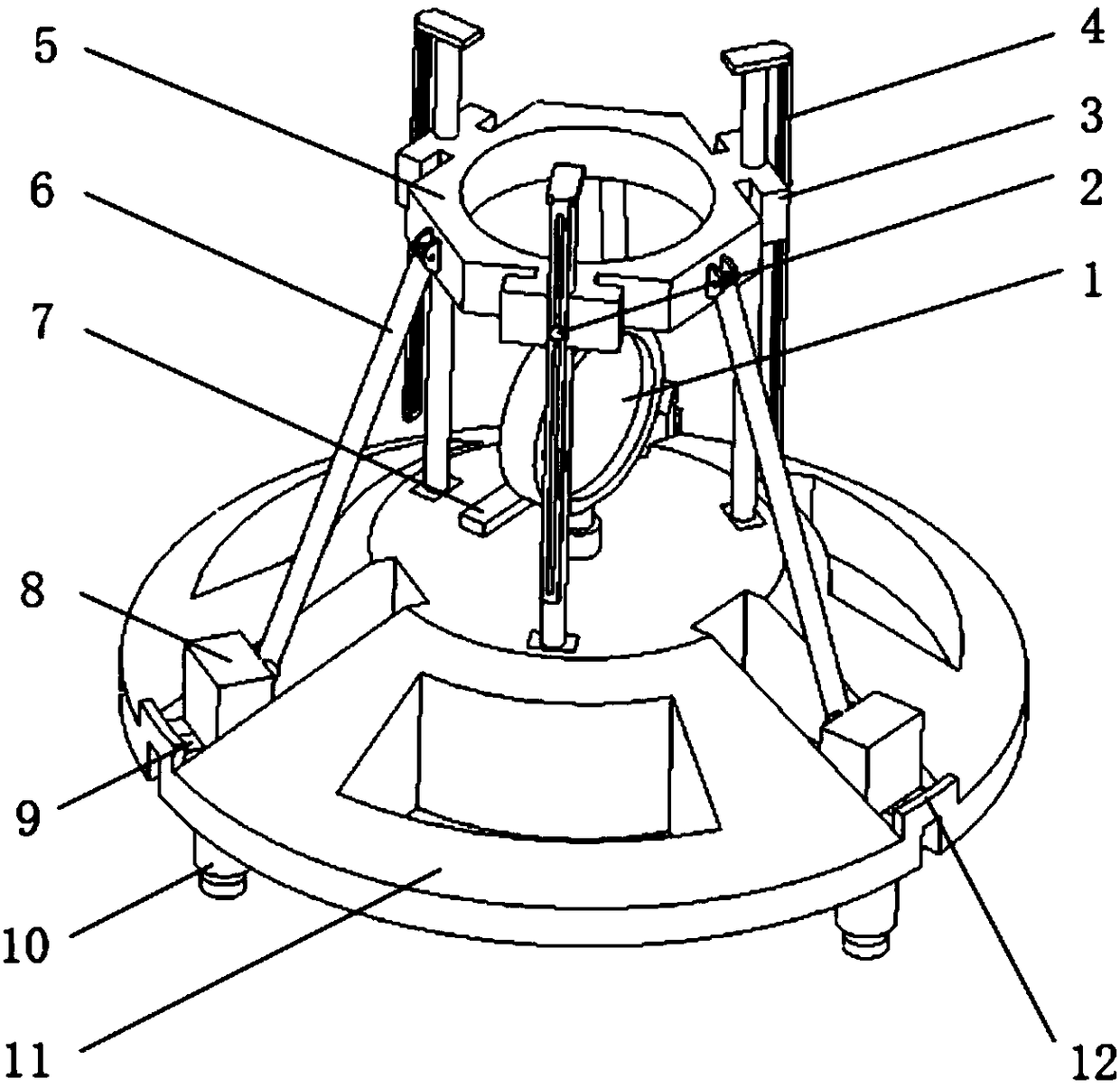

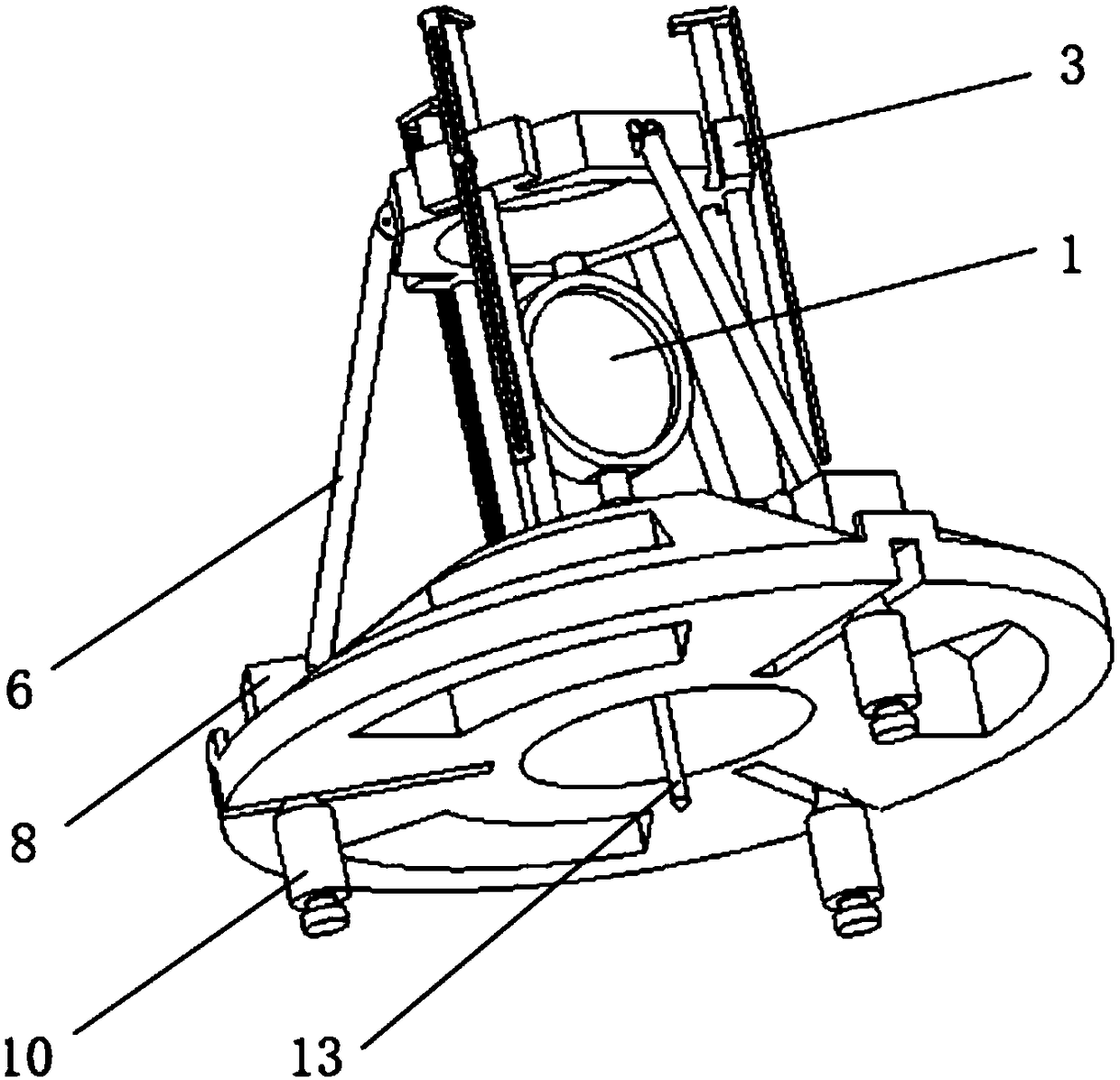

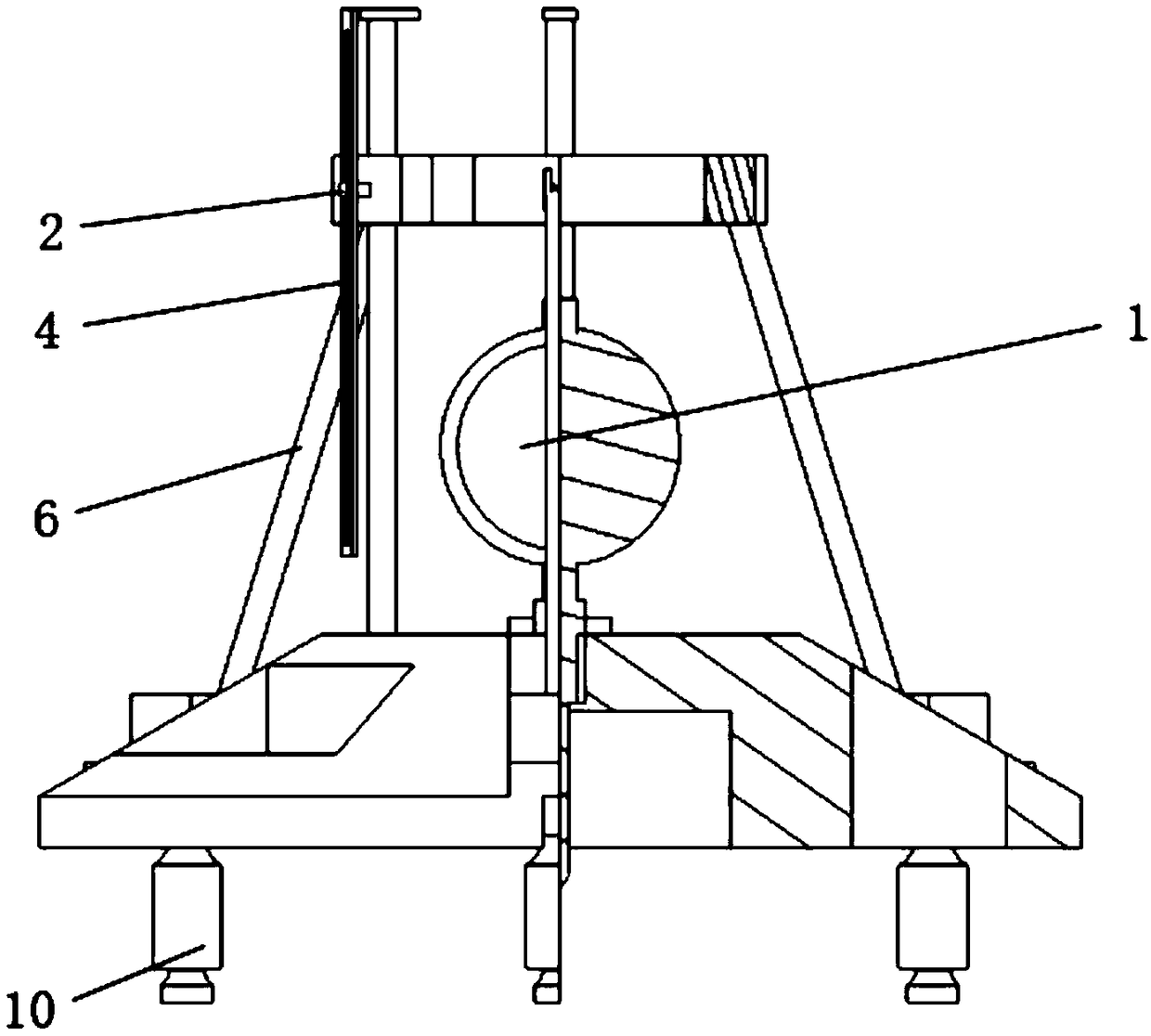

[0042] The present invention is described in further detail below in conjunction with accompanying drawing:

[0043] Such as Figure 1 to Figure 7As shown, a spherometer with adjustable measuring diameter includes an indicator gauge 1 and a fixed base 11 for installing the indicator gauge 1. The fixed base 11 is provided with a through hole, and the indicator gauge 1 is fixedly installed on the through hole of the fixed base 11. In the hole, the fixed base 11 is provided with at least three vertical guide rails 4 around the center of the through hole, and also includes a lift platform 5 that can slide up and down relative to the vertical track 4. Two vertical guide rails 4 are engaged with sliding sliding ears 3 at the same time, and locking nuts 2 are provided on the sliding ears 3, which are used to lock and fix the lifting table 5 and the vertical rails 4. Specifically: the sliding ears 3 are provided with a set Set in the through hole 14 of the vertical track 4, the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com