Concrete-high-compaction bentonite composite system behavior simulation test method and device

A kind of simulation test, bentonite technology, applied in the direction of measuring device, using stable tension/pressure test material strength, suspension and porous material analysis, etc., to achieve good sealing effect, convenient detection and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

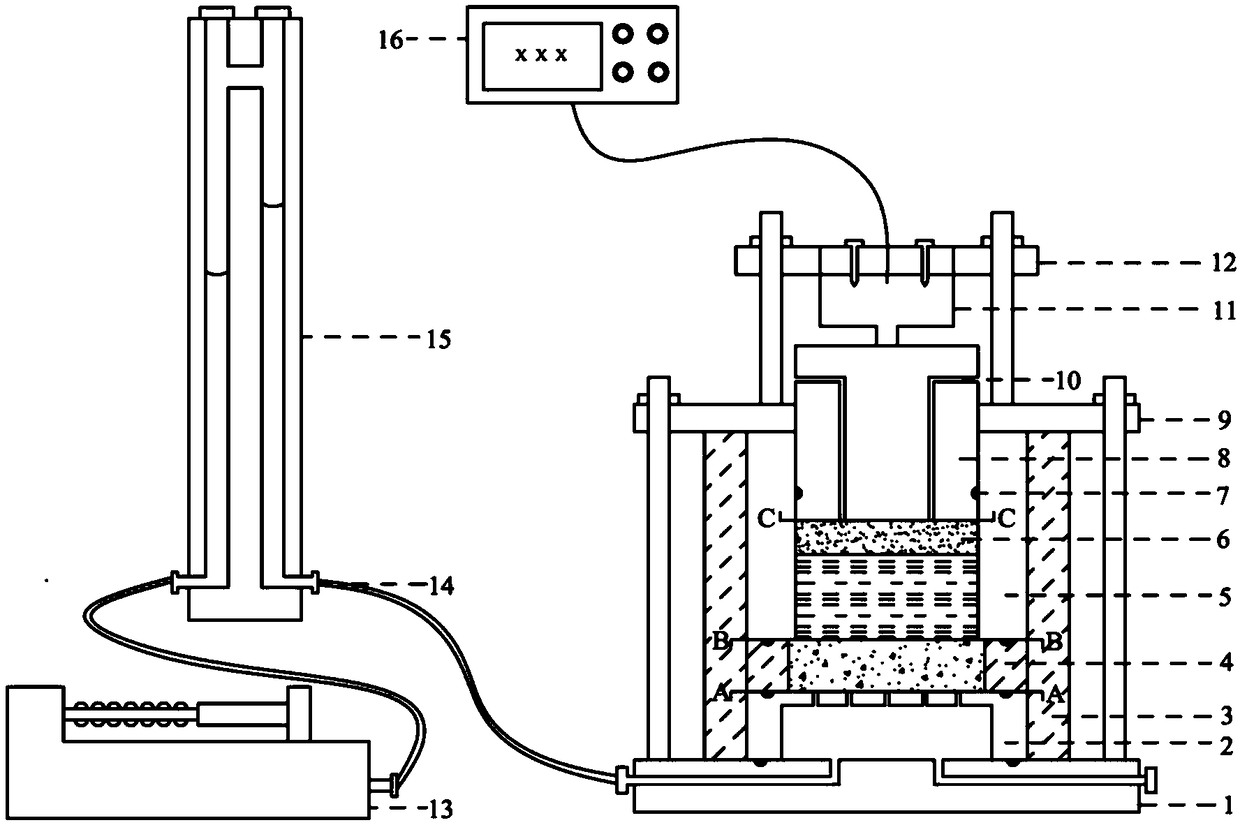

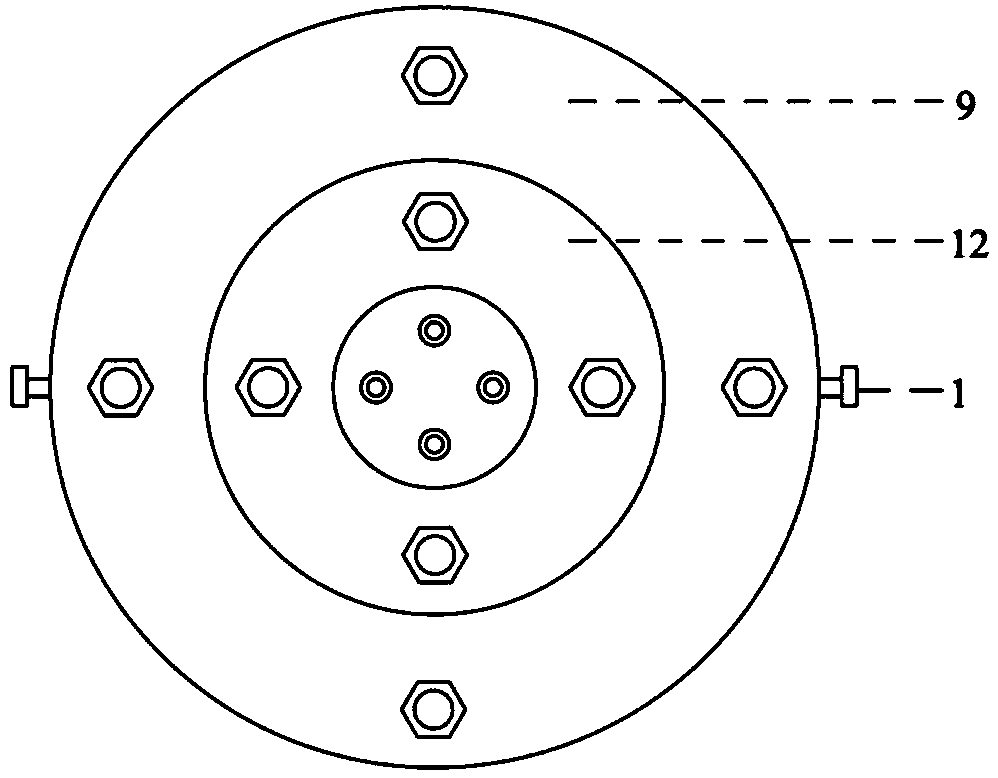

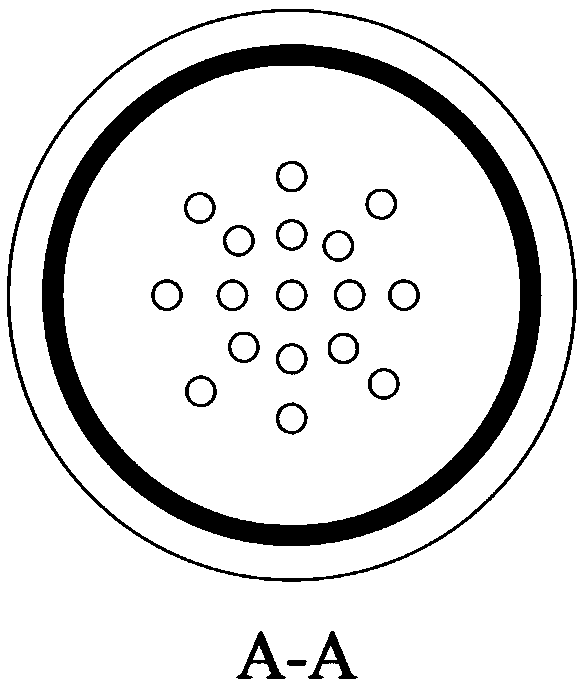

[0033] Such as Figure 1 to Figure 3c As shown, the concrete-high compacted bentonite composite system performance simulation test device provided by the present invention includes three parts: concrete / bentonite contact interface Mock-up device, liquid injection control device and measuring device:

[0034] 1) The concrete / bentonite contact interface Mock-up device includes a base 1, a solution chamber 2, a sleeve 3, a concrete sample ring 4, a bentonite sample ring 5, a permeable stone 6, a sealing ring 7, a piston 8, a lower Top cover 9, upper top cover 12. Among them, the base 1, the solution chamber 2, the bentonite sample ring 5, the piston 8, the lower top cover 9, and the upper top cover 12 are made of stainless steel, and the sleeve 3 and the concrete sample ring 4 are made of polytetrafluoroethylene.

[0035]The base 1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com