Off-axis three-reflex optical system with 350mm aperture, 1778.9mm focal length and 0.4-5mu m wave band

An off-axis three-mirror and optical system technology, applied in the field of target simulation, can solve problems such as short focal length, inability to meet the calibration and detection of multi-visual axis photoelectric tracking system, and small exit pupil diameter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

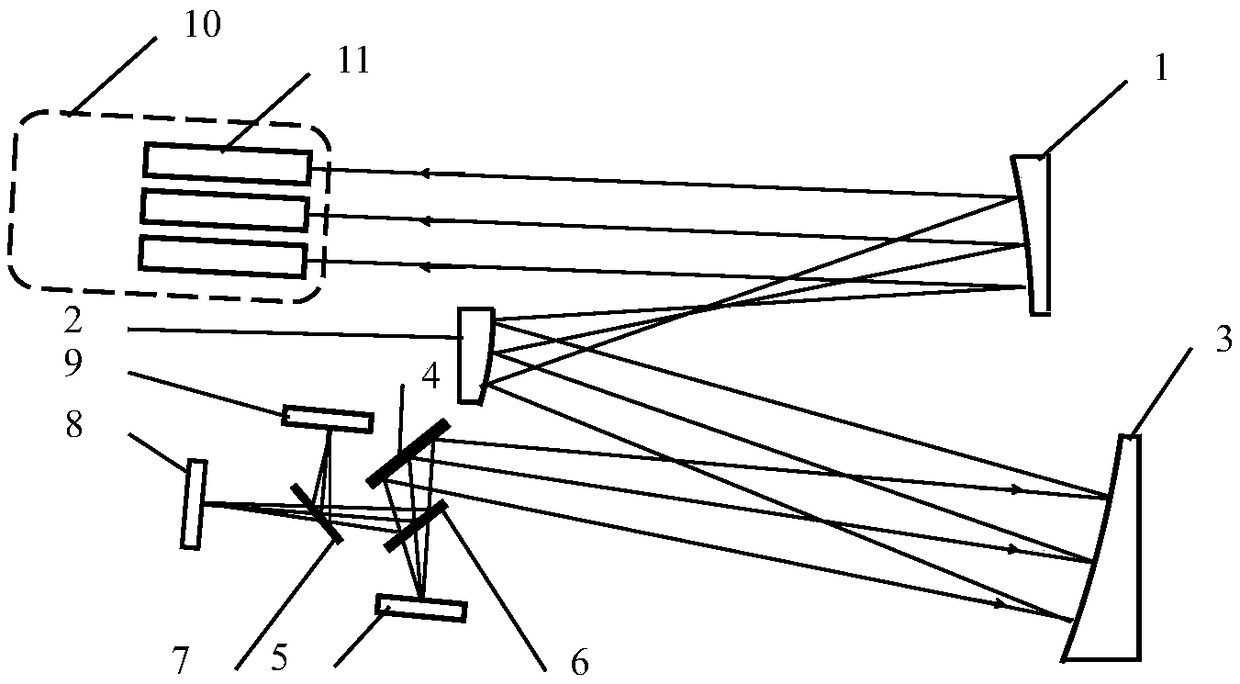

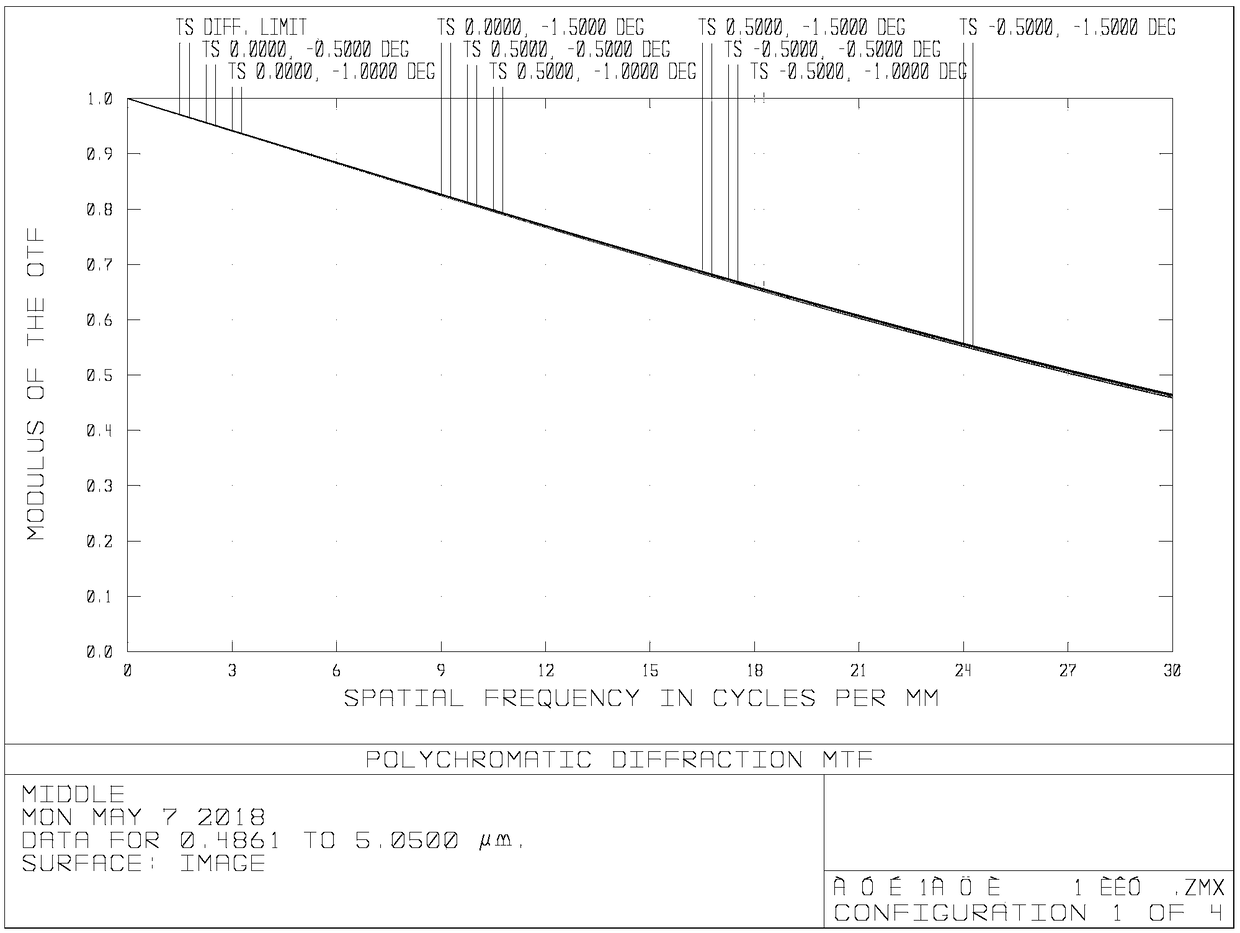

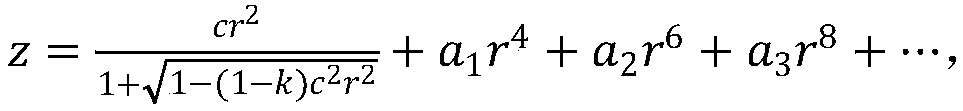

[0012] The 350mm diameter 1778.9mm focal length 0.4 ~ 5μm band off-axis three-mirror optical system of the present invention is composed of a primary mirror 1, a secondary mirror 2 and a triple mirror 3, such as figure 1 As shown, the center of curvature of the mirror surfaces of primary mirror 1, secondary mirror 2, and third mirror 3 is located on a straight line, and the tangents of the intersection points of the straight line and each mirror surface are parallel to each other; the materials of primary mirror 1, secondary mirror 2, and third mirror 3 are all for silicon carbide. The primary mirror 1 and the third mirror 3 are high-order aspheric reflectors with a square aperture, and the secondary mirror 2 is a spherical reflector with a circular aperture; the primary mirror 1 is a positive power reflector with a radius of curvature of -2980mm and a clear aperture of 560mm×570mm, the off-axis distance is 410mm, the secondary mirror 2 is a negative power mirror, the radius o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com