Transverse microstructure generation method of unidirectional long fiber reinforced composite

A technology for enhancing composite materials and microstructures, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as pores and random distribution of fibers that are not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

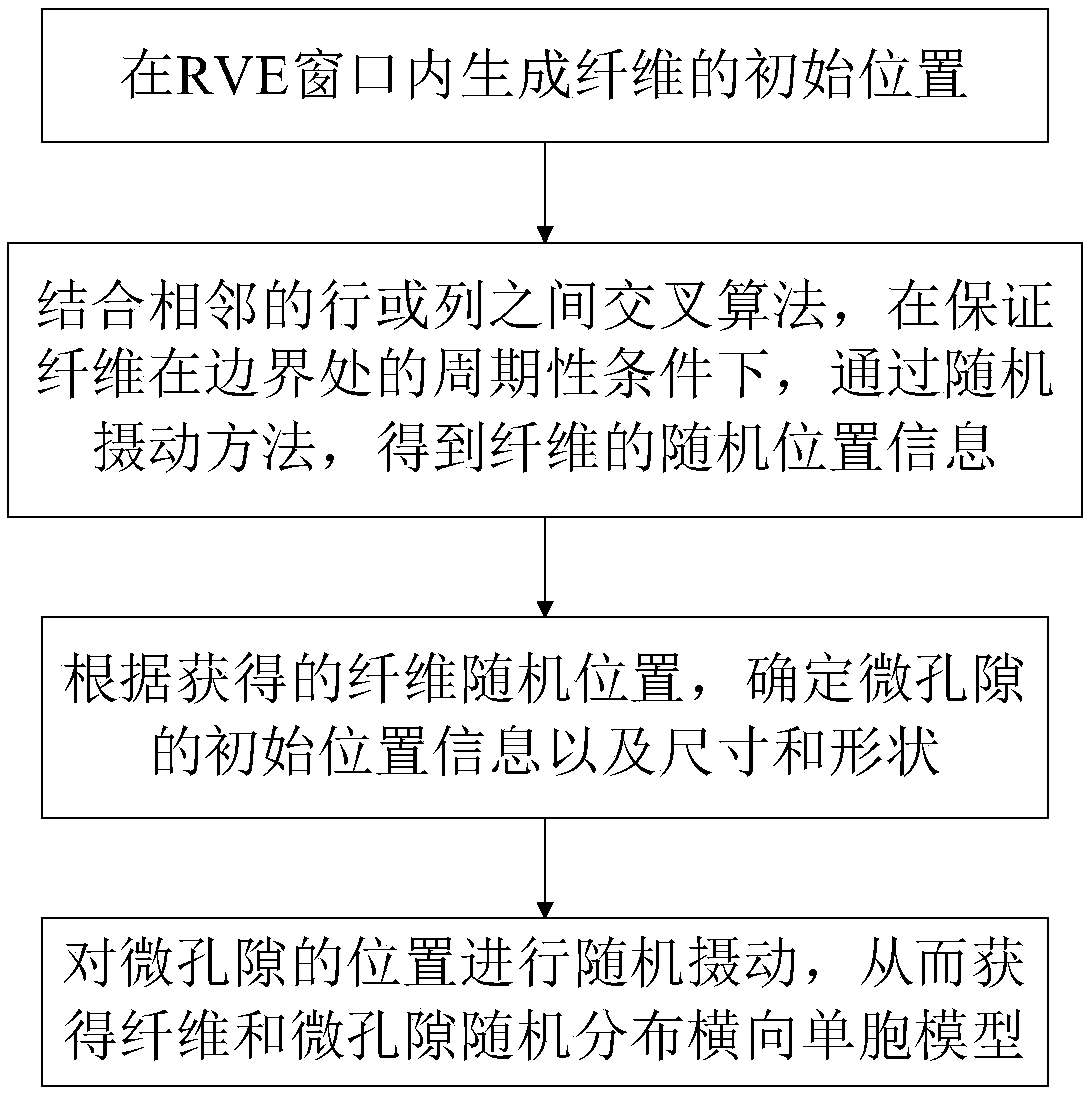

[0029] A method for generating transverse microstructures of unidirectional long fiber reinforced composites, such as figure 1 As shown, the specific operation is as follows:

[0030] Step (1) Determine the initial position of the fiber within the RVE window:

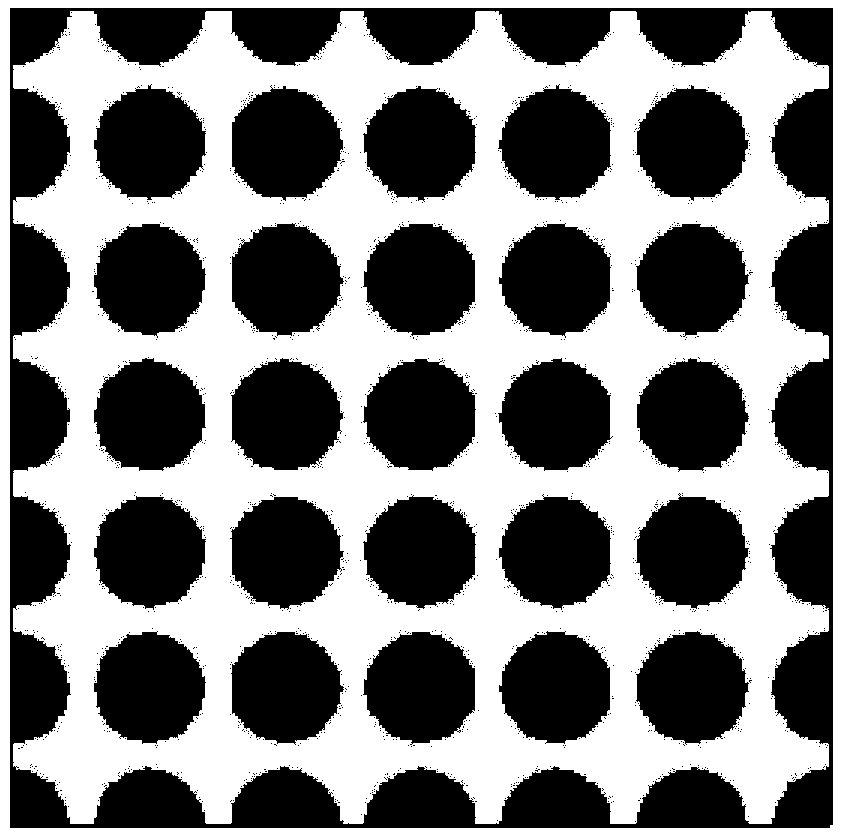

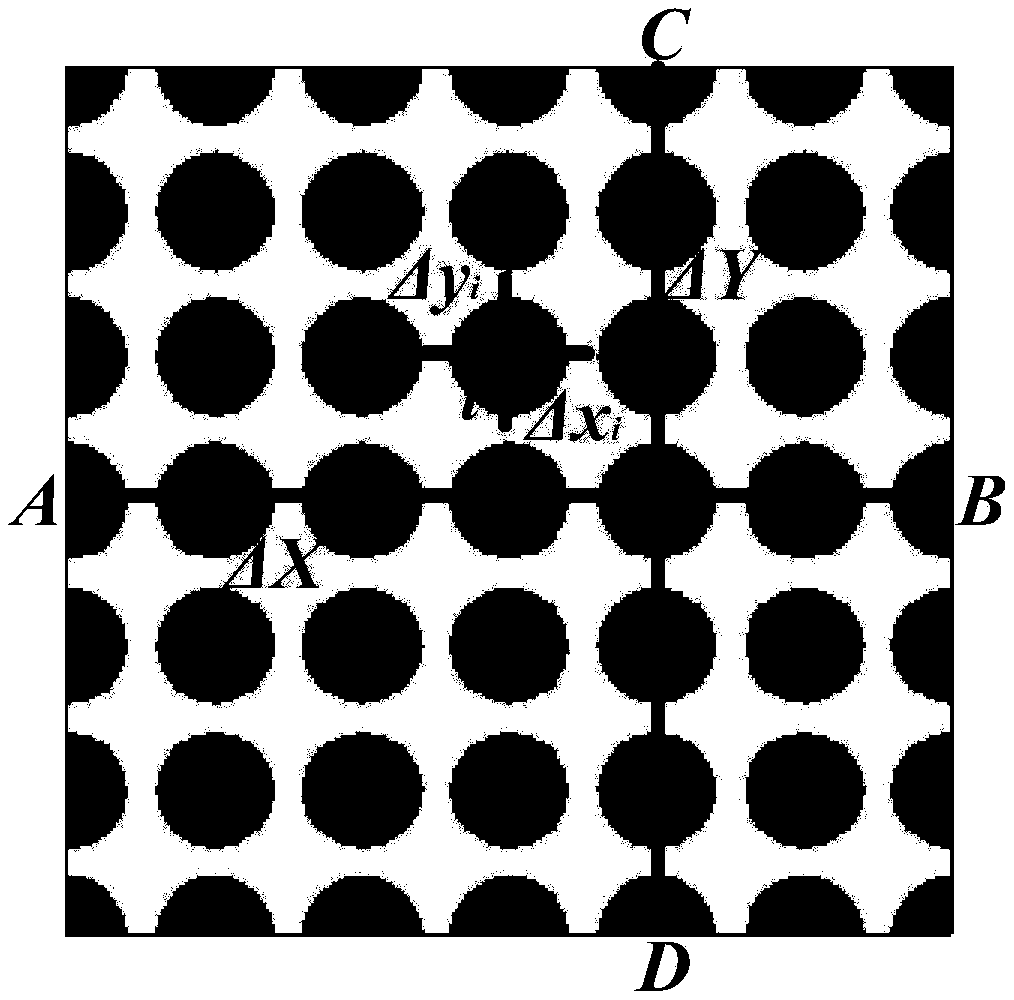

[0031] 1.1) Determine the initial parameters of the RVE model: the initial parameters of the model include the RVE window (square or rectangle on the x-y plane of the coordinate axis, choose a square here), side length s, fiber volume content V f , fiber radius r, complete fiber number n and pore volume content V v , where s=37.6μm, V f =50%, r=5μm, n=36, V v = 1%;

[0032] 1.2) Generate the coordinate position of the periodic distribution of fibers within the RVE window: select a unit cell model that uses the square distribution of fibers,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com