A soft start control method for LLC full bridge converter based on variable duty cycle

A technology of full-bridge converter and variable duty ratio, which is applied in the direction of output power conversion devices and electrical components, etc., which can solve the problems of heat damage of power devices, affecting the normal operation of the system, and excessive current impact, etc., to reduce the current Shock, circuit soft start process is stable and reliable, charging current impact is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. But the implementation of the present invention is not limited thereto.

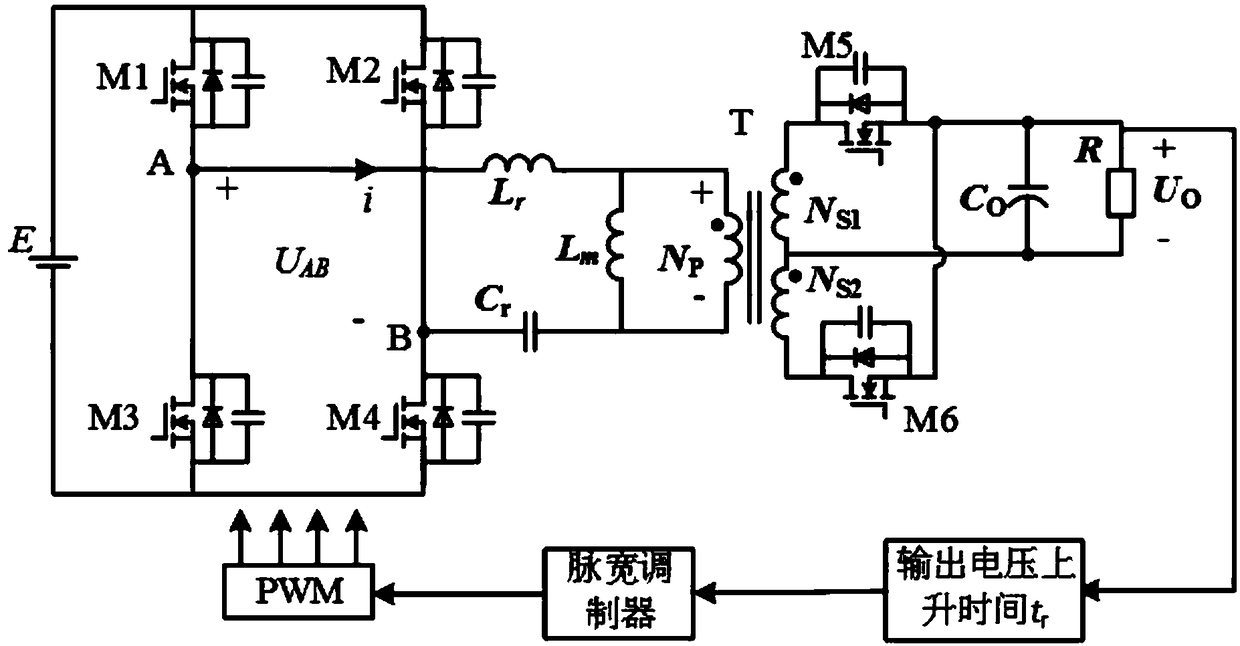

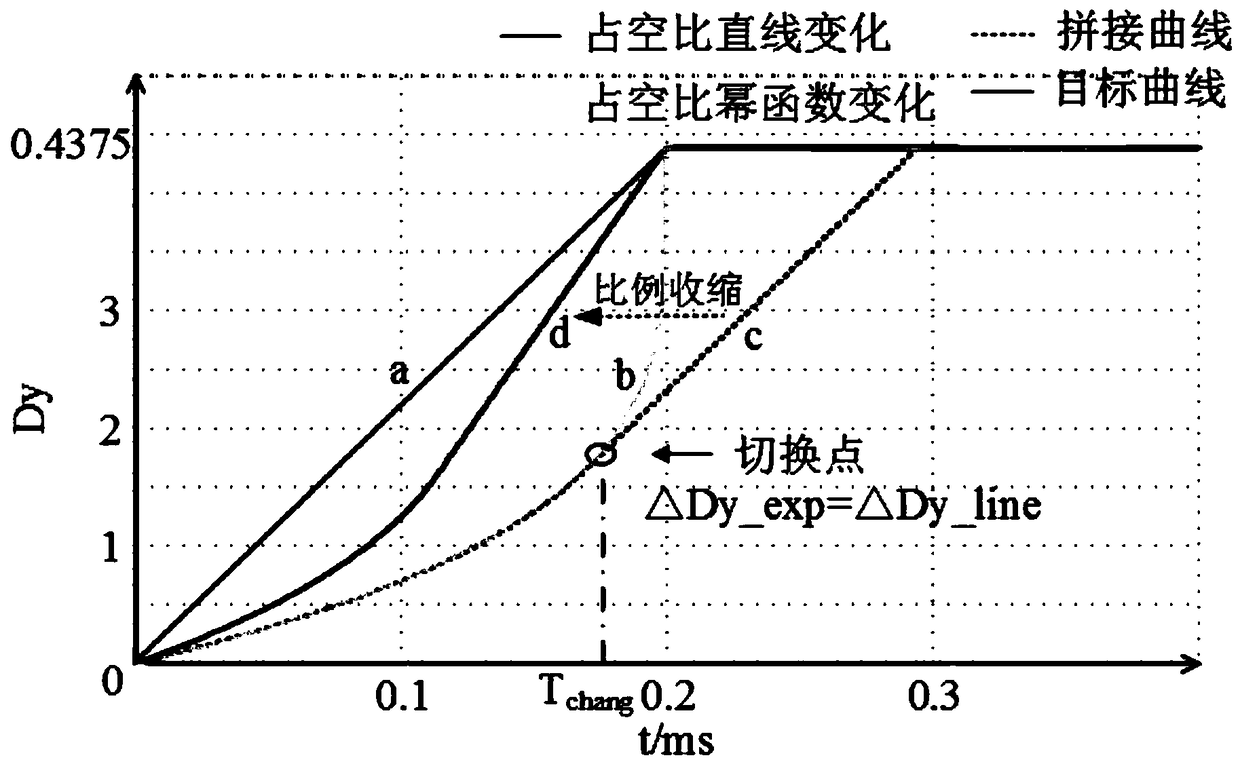

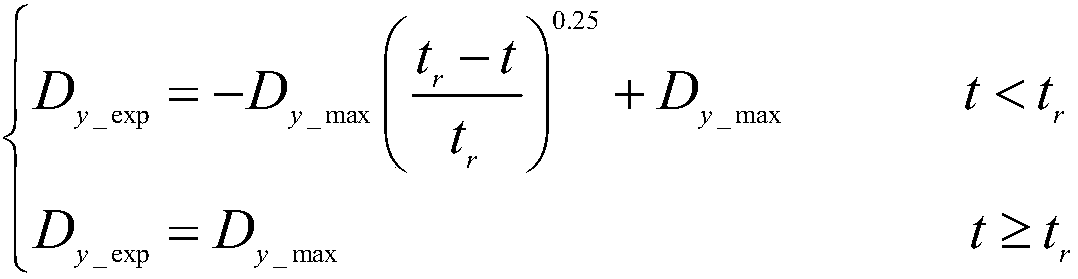

[0022] Such as figure 1 As shown, it is a schematic diagram of the soft-start control strategy of the LLC full-bridge converter based on variable duty ratio. The main power circuit shown in the figure is the LLC full-bridge converter, and the peripheral control circuit includes the connected pulse width modulator and drive module. The control method provided in this embodiment is mainly to control the four MOSFETs on the primary side of the LLC full-bridge converter, so that the signals of the upper and lower switching tubes of the same bridge arm are complementary, and the upper tube of the left bridge arm is 50% ahead of the upper tube of the right bridge arm. cycle, and at the same time get the start-up time t according to the output voltage r , adjust the duty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com