Method for the automated electronic control of a braking system and electronically controllable braking system in a utility vehicle

A braking system and commercial vehicle technology, applied in the direction of braking system interaction, braking safety system, braking control system, etc., can solve problems such as inattention, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

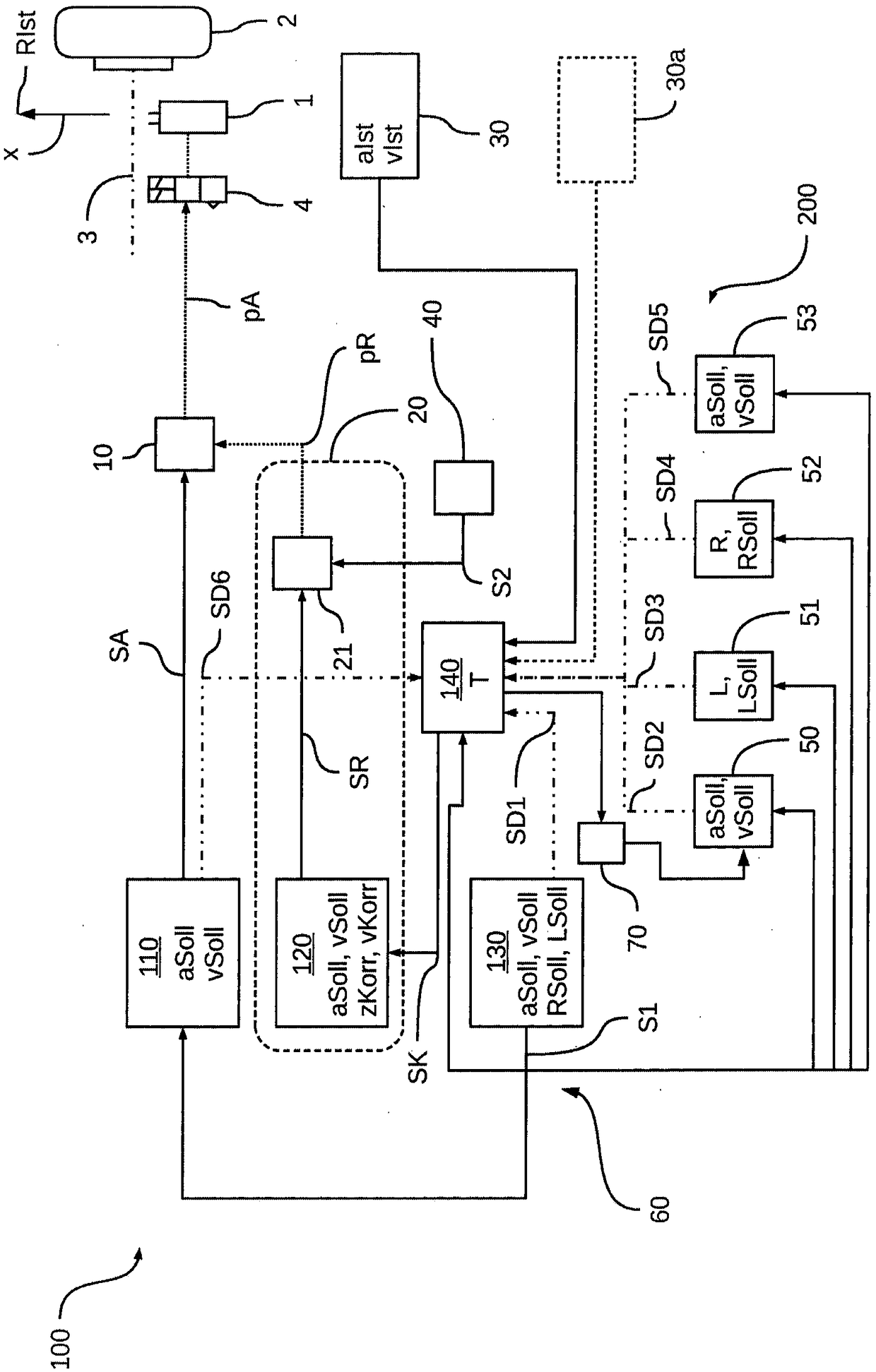

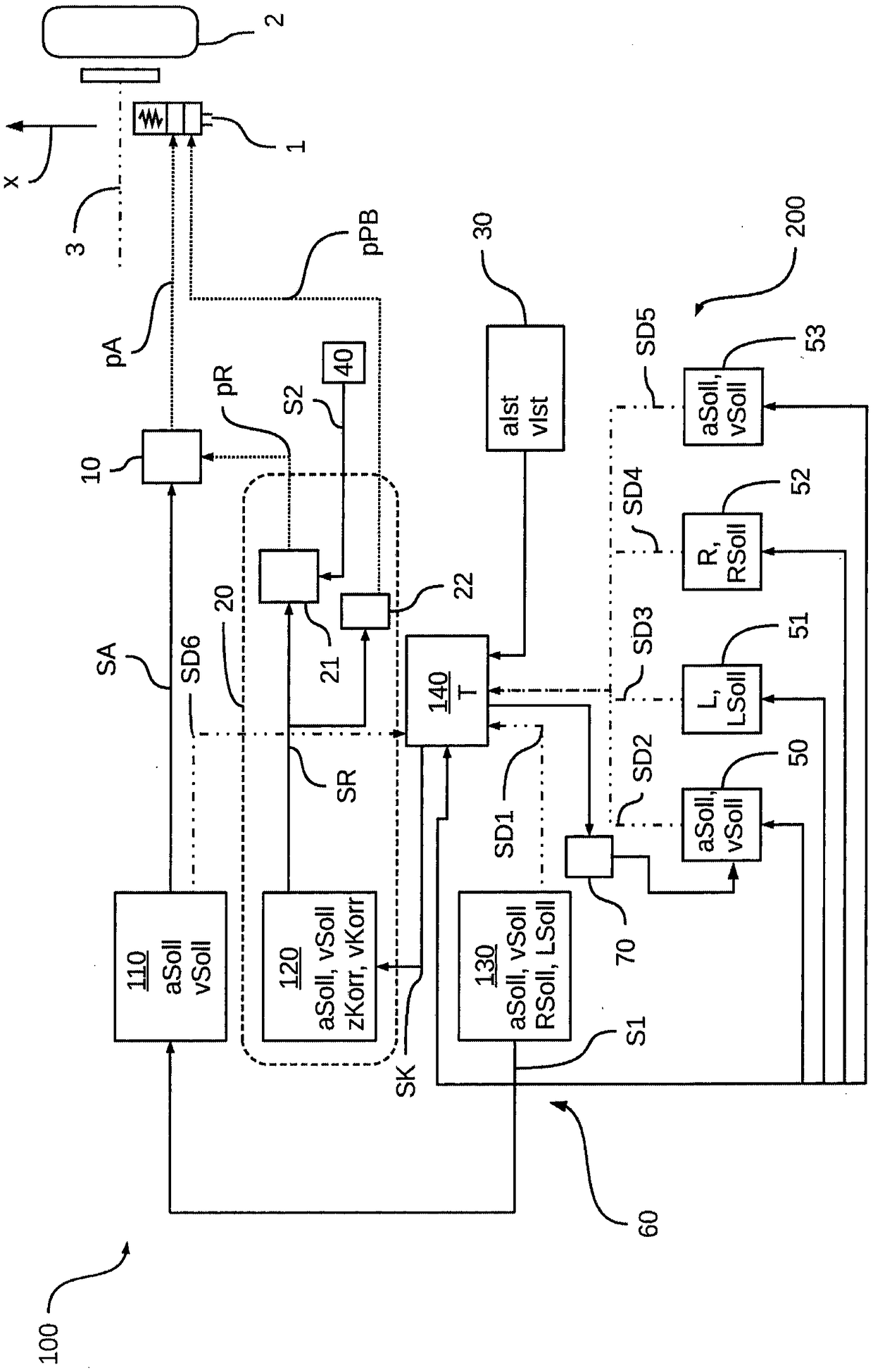

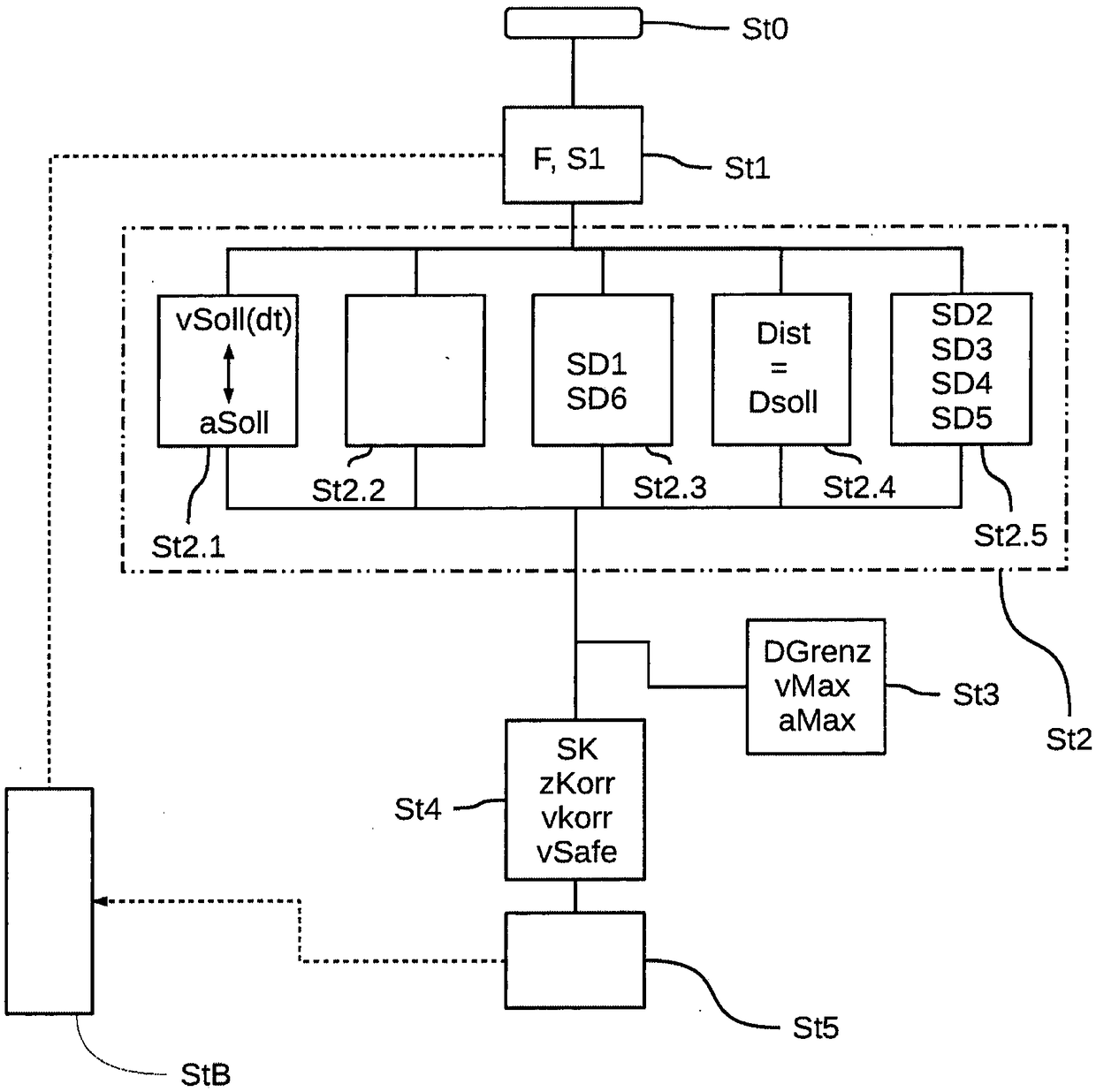

[0062] in accordance with figure 1 In an embodiment of the present invention, a section from brake system 100 of vehicle 200 is shown as a block diagram. Braking system 100 thus has a first control device 110 , a second control device 120 and a monitoring device 140 . Braking system 100 is designed to decelerate vehicle 200 via wheel brakes 1 , which are each assigned to wheels 2 of an axle 3 and optionally upstreamed by electronically controllable ABS brake valves 4 . For simplicity, in accordance with figure 1 Only the right front wheel 2 of the front axle 3 of the vehicle 200 is shown in the embodiment of the example. The other wheels can be implemented in a corresponding manner with or without ABS brake valve 4 .

[0063] Furthermore, a control device 130 is shown, which is assigned to a control system of the vehicle 200 , which is designed to be automatically controlled, for example, as a function of the planned vehicle movement F, in particular taking into account the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com