Outlet valve for a flush tank and flush tank having an outlet valve

A technique for drain valves and flush tanks, applied in the field of sanitary flush tanks, which can solve problems such as difficulty in dismantling drain valves, and achieve the effect of improving and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

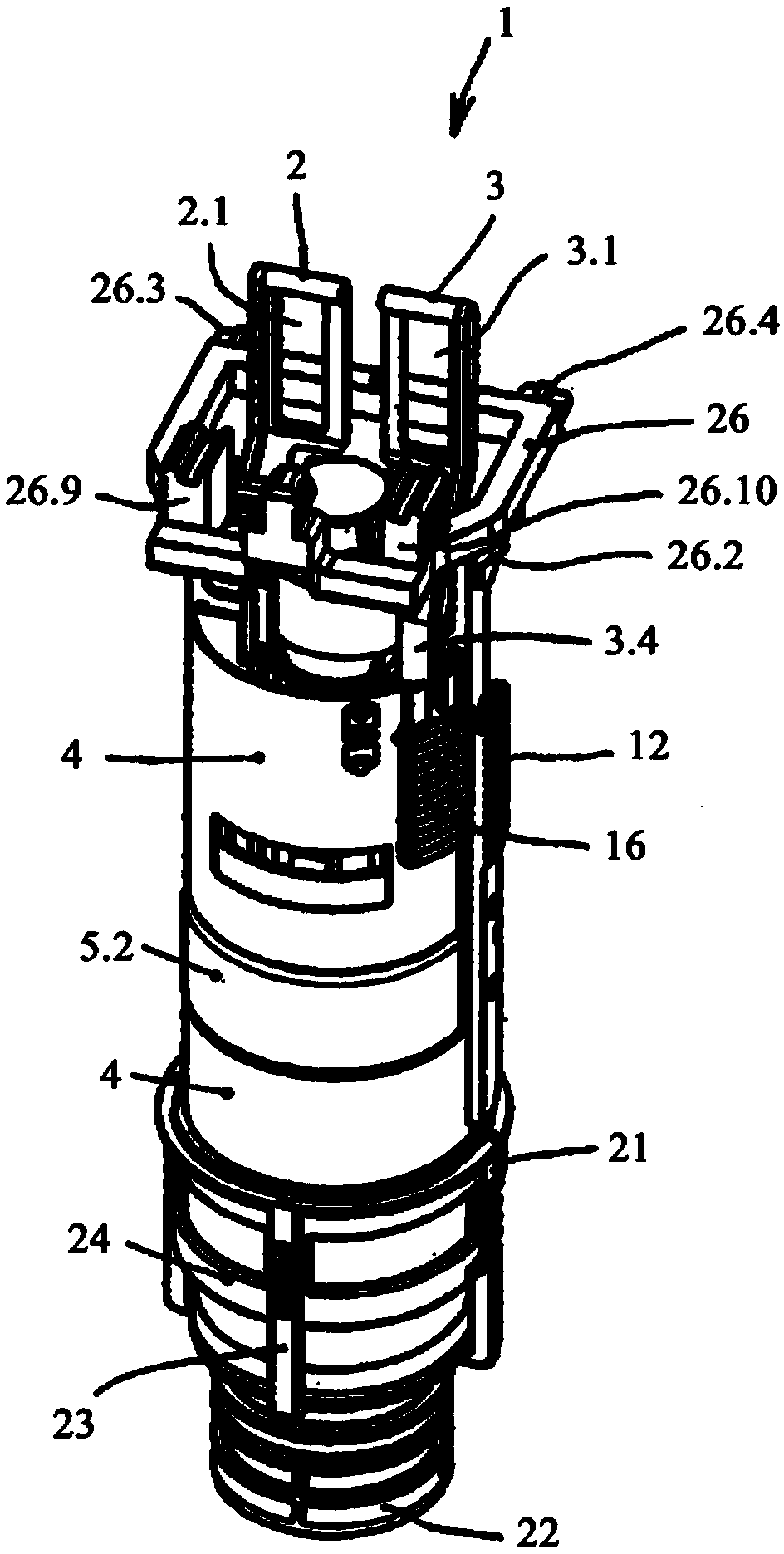

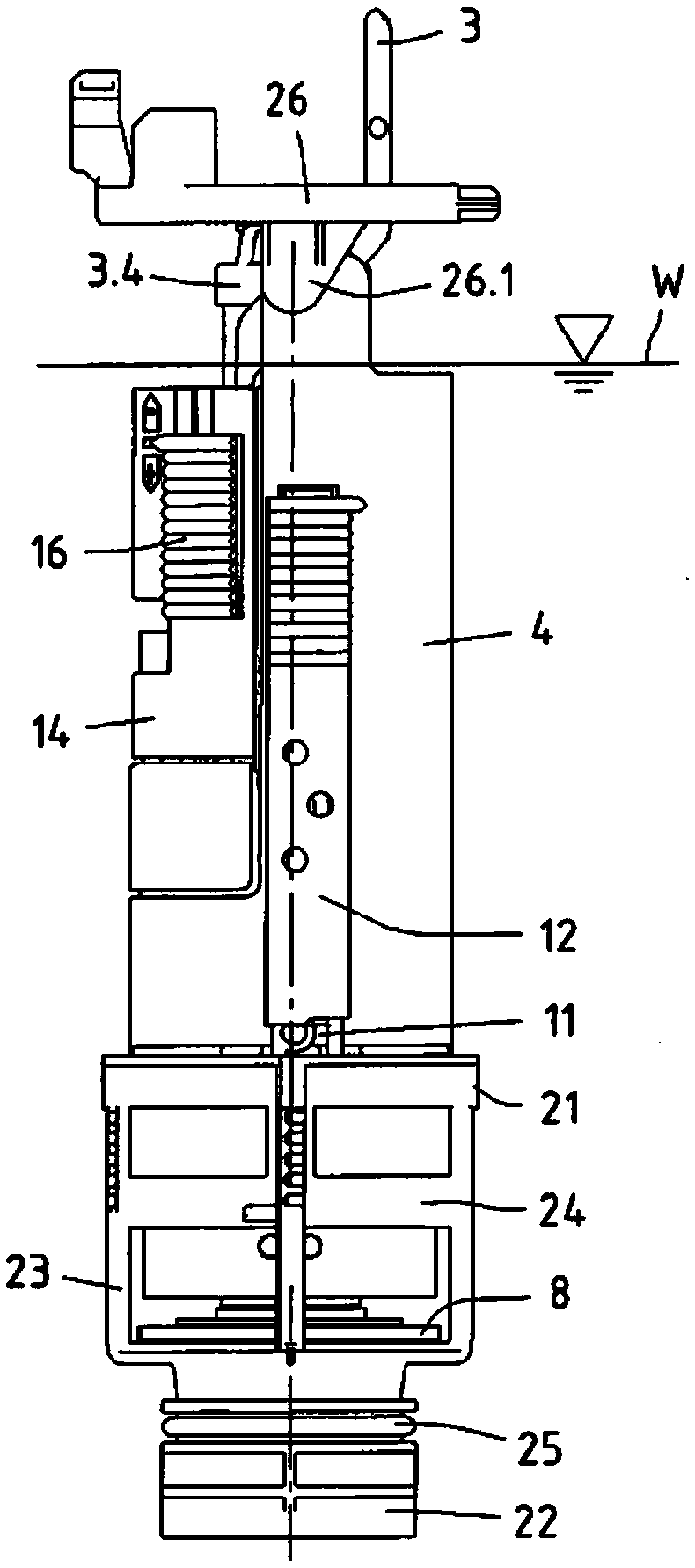

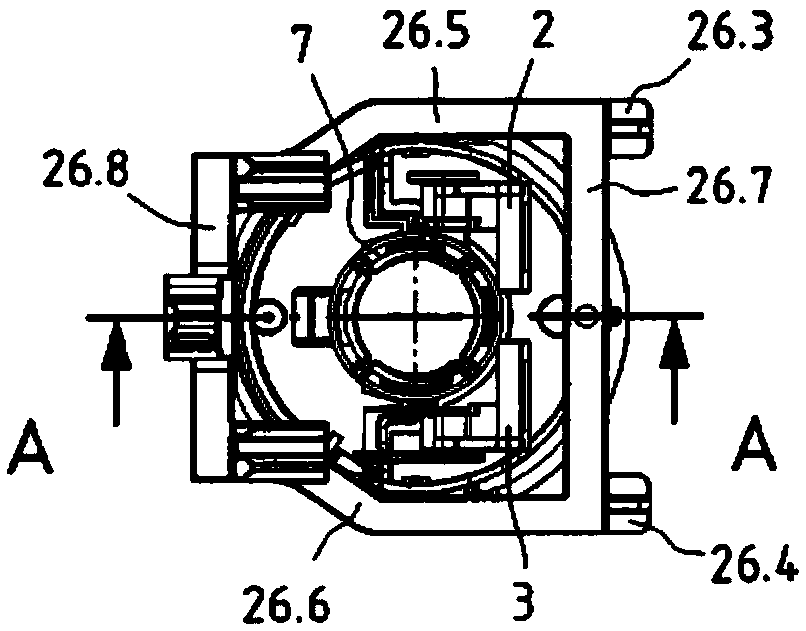

[0026] The figures of the figures show a drain valve 1 which can be installed in a sanitary cistern, in particular in a concealed cistern. The drain valve 1 is preferably designed as a dual-displacement drain valve, ie a larger flush volume for so-called full flushes or a smaller flush water volume for so-called partial flushes can be selectively delivered by means of the drain valve. For operating the drain valve 1 , an operating device (not shown) is arranged in the upper region of the tank. The operating device has two operating elements that can be controlled independently of one another. By way of example, the operating elements are implemented as movably mounted pushbuttons, wherein each pushbutton is assigned a lifting mechanism (not shown). The respective lifting mechanism is coupled to one of the two pull tabs 2, 3 of the drain valve 1, which has at its upper end an elongated lug 2.1, 3.1 in which the lifting mechanism engages.

[0027] The drain valve 1 has a subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com