Modularized detachable VOCs gas absorbing and purifying facility and applications thereof

A technology of gas absorption and purification equipment, which is applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc., which can solve the problems such as difficulty in achieving exhaust gas purification effect, low purification and filtration efficiency, inconvenient loading and unloading of carbon, etc., to achieve the protection of VOCs purification Effect, equipment life cycle protection, effect of equipment life cycle extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

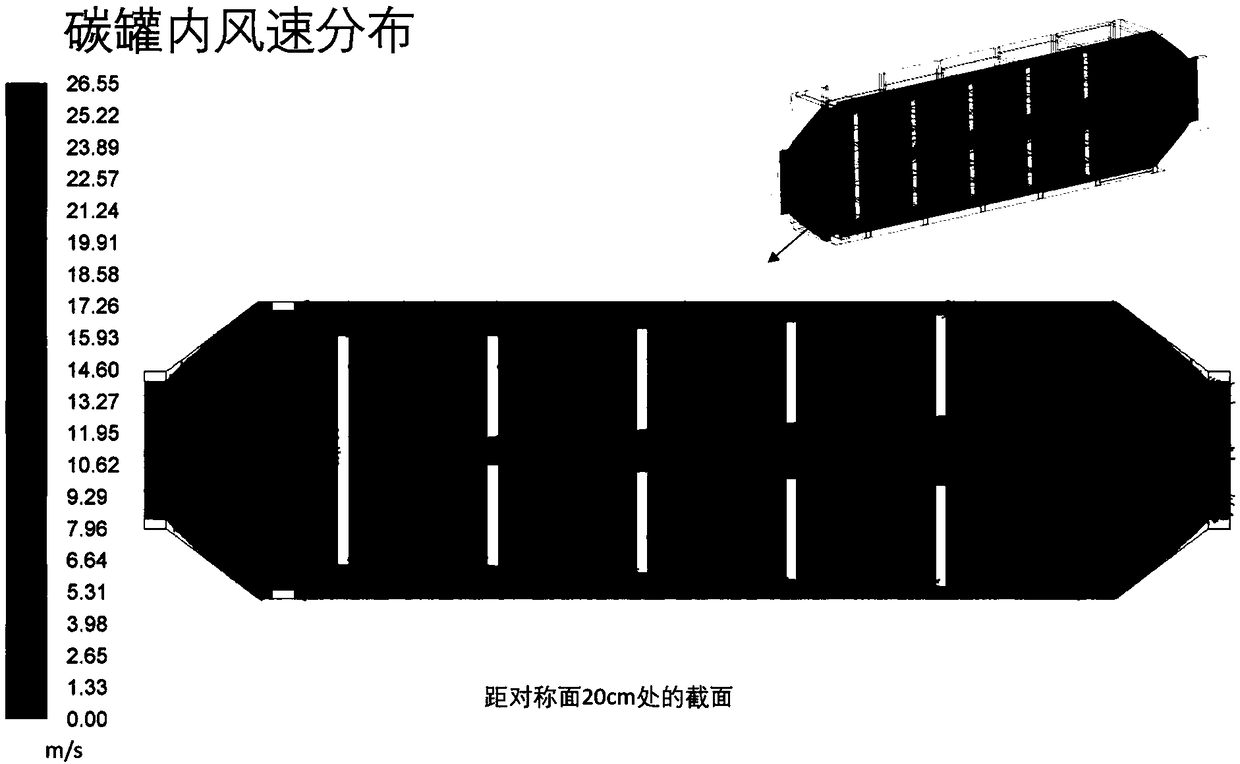

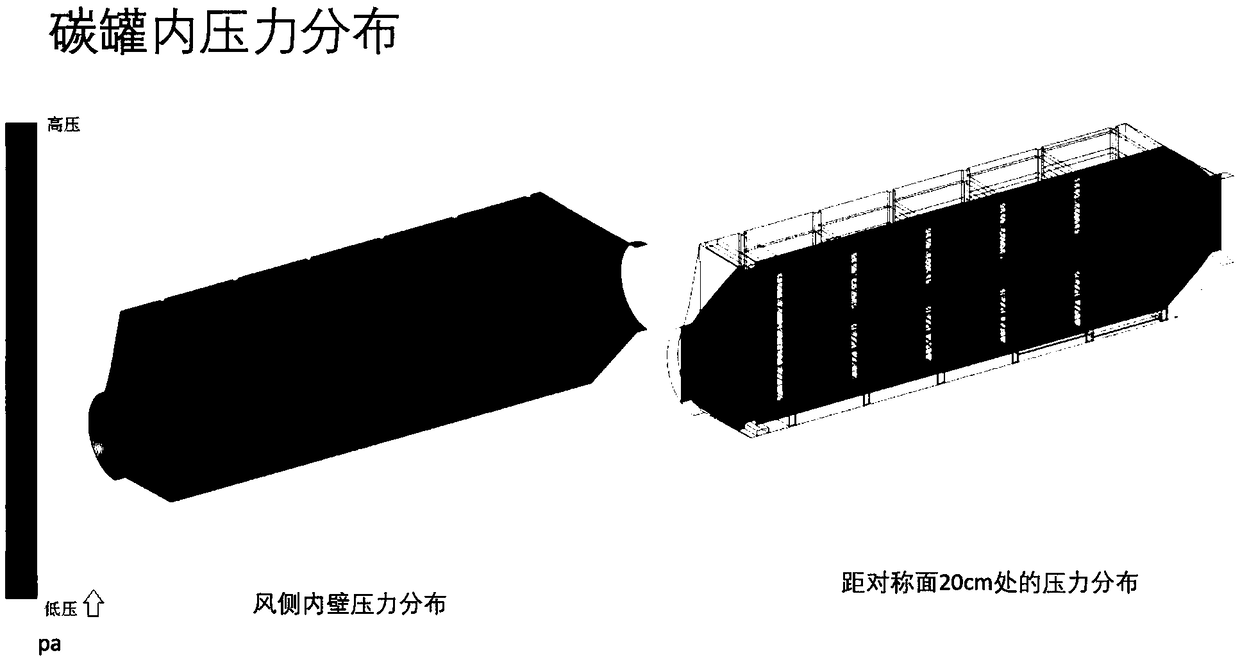

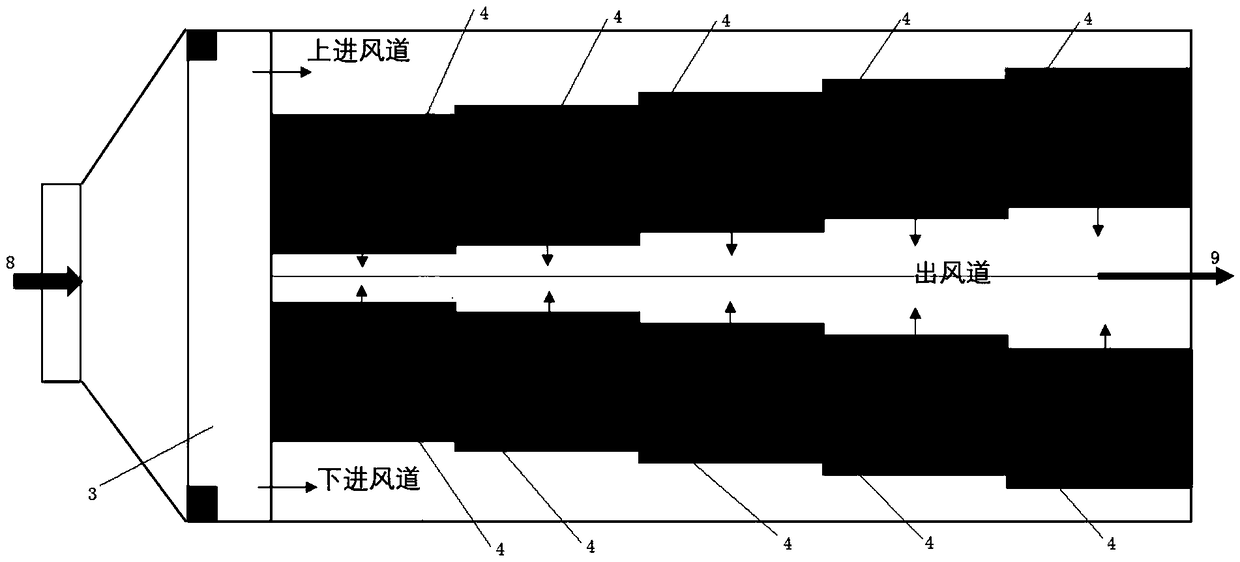

[0033] This embodiment provides a modular detachable VOCs gas absorption and purification equipment 1, including a pressure measuring valve 2, a filter device 3, an activated carbon box 4, a carbon bag, a spray pipe 5, a windshield, a deflector 6, and a drain valve 7. Air inlet 8, air outlet 9, support column 10, sealing plate 11.

[0034] In an embodiment, the modular detachable VOCs gas absorption and purification equipment may be simply referred to as: equipment.

[0035] Modular detachable VOCs gas absorption and purification equipment 1 can be designed according to the actual working conditions. The material is made of high-quality steel such as: Q235B\304\316L\32205. For special corrosive medium conditions, PP or Made of stainless steel material. The pressure measuring valve 2 is arranged near the upper edge of the middle part of the modular detachable VOCs gas absorption and purification equipment 1 air inlet 8, air outlet 9 and the modular detachable VOCs gas absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com