Electric locomotive roof insulator washing machine

A technology for roof insulation and electric locomotives is applied in the directions of cleaning methods and appliances, cleaning methods using liquids, cleaning methods using tools, etc. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

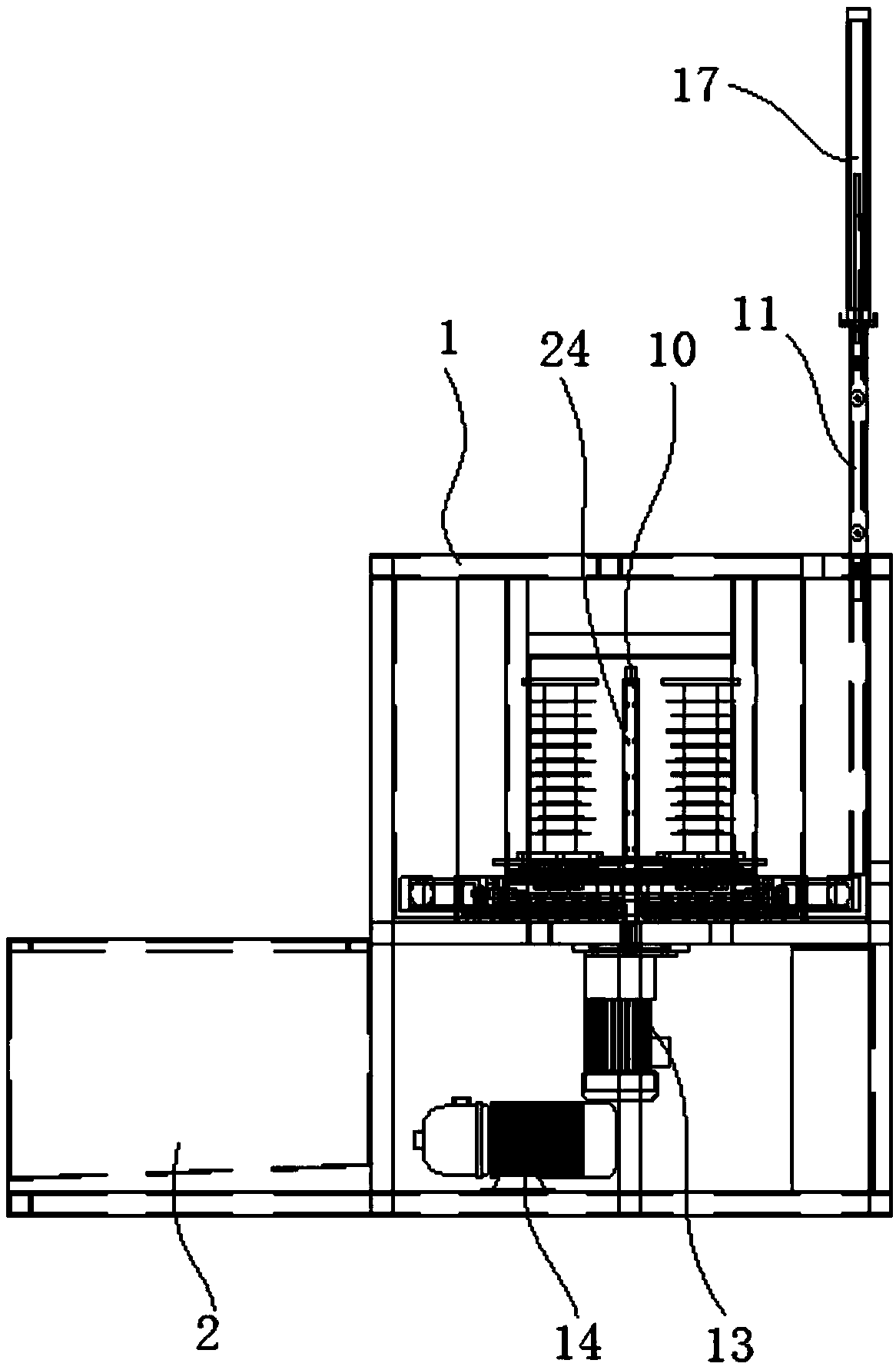

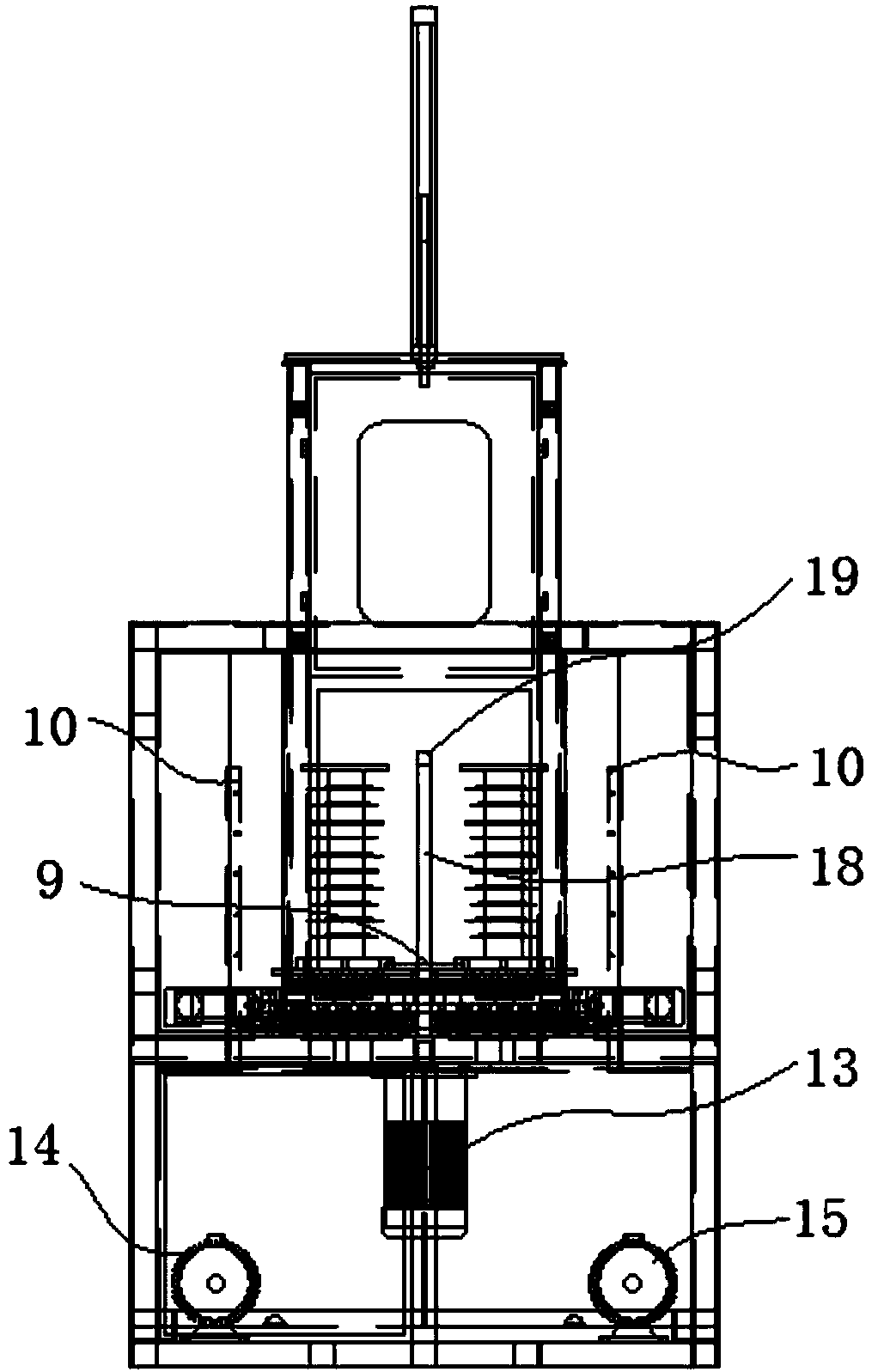

[0025] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

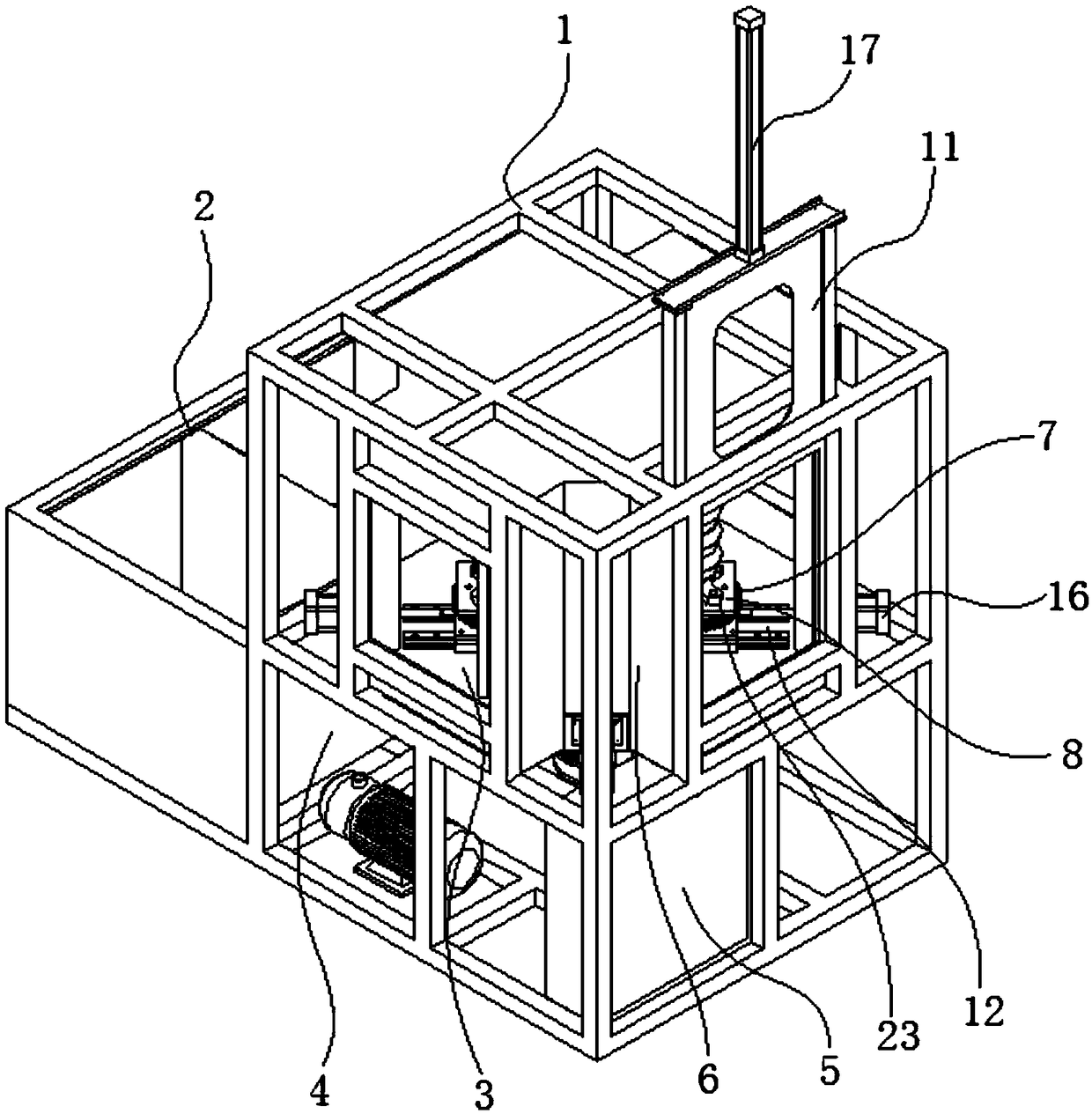

[0026] Such as Figure 1-4As shown, a cleaning machine for roof insulators of an electric locomotive includes a frame-type three-dimensional frame 1, a liquid storage tank 2, a cleaning room 3, a mechanical room 4, an electric control box 5 and a control panel 6, the cleaning room 3, the mechanical The room 4, the electric control box 5 and the control panel 6 are all set on the frame 1, the cleaning room 3 is located in the middle of the mechanical room 4, and is wrapped by the frame 1, and the liquid storage tank 2 is set on the frame 1 On one side, the electric control box 5 and the control panel 6 are located outside the mechanical room 4, the control panel 6 is located at the upper part, and the electric control box 5 is located at the lower part. The cleaning chamber 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com