Double three-dimensional eight-target four-wheel alignment system

A four-wheel alignment system and three-dimensional technology, which is applied in wheel testing and other directions, can solve the problems of prolonging the four-wheel alignment process time, and achieve the effects of reducing four-wheel alignment time, quick installation, and improving maintenance production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

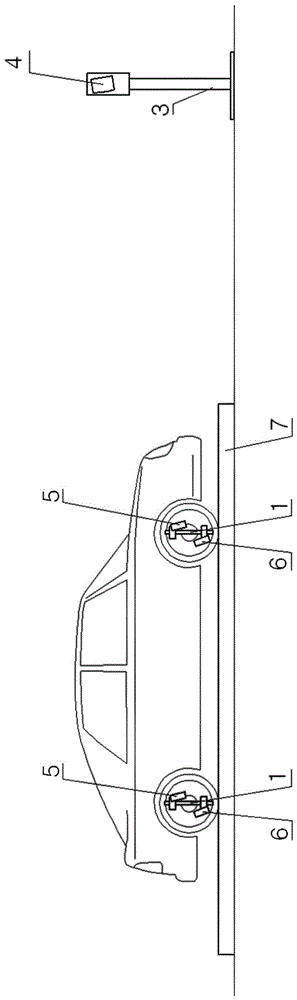

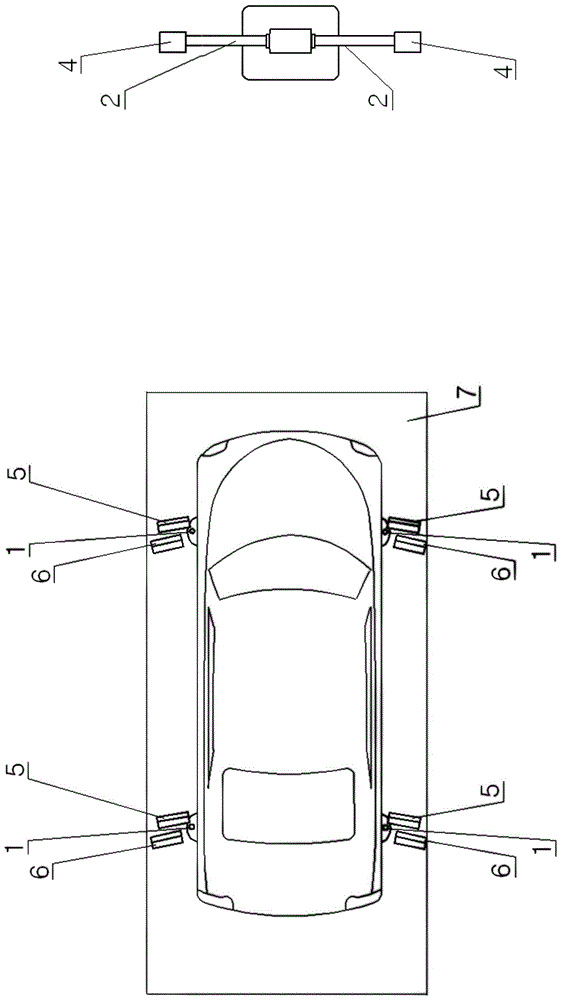

[0016] The same as the traditional four-wheel alignment system, the present invention includes a target target, a target fixture, a camera beam and a computer; digital cameras are installed on the left and right sides of the camera beam; and the digital camera is connected to the computer.

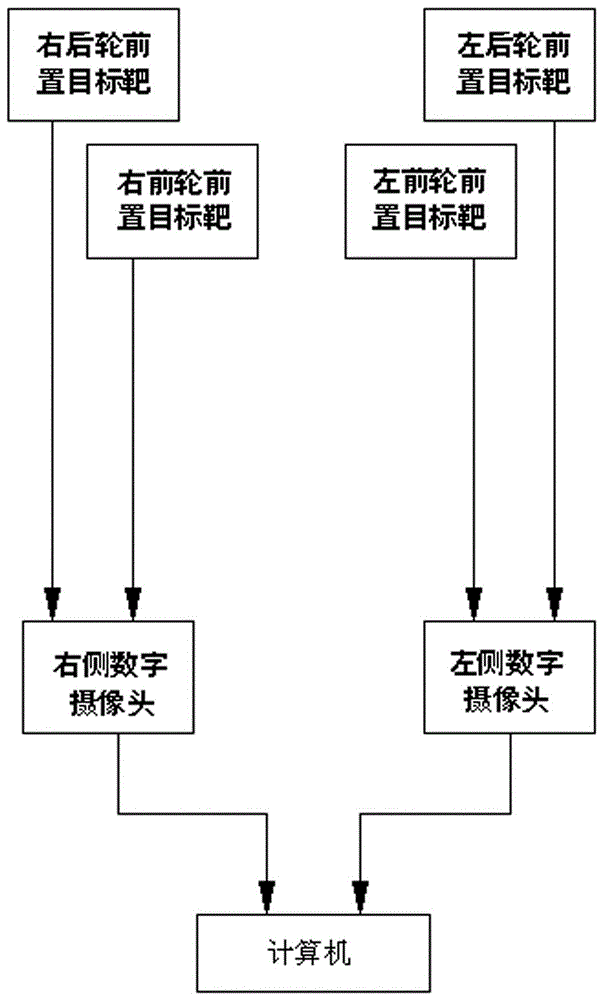

[0017] Different from the traditional system, the present invention is configured with eight targets, and each target fixture is fixed with two targets, and one of the two targets on each target fixture and the digital camera form the first measurement subsystem, The other of the two target targets on each target fixture and the digital camera form the second measurement subsystem; the computer obtains two sets of mutually independent four-wheel alignment data from the first measurement subsystem and the second measurement subsystem respectively; the computer passes The operation of a dual-system compensation module generates four-wheel alignment verification results based on two sets of fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com