Lathe tailstock moving device

A technology of moving device and tailstock, which is applied in tailstock/top, turning equipment, tool holder accessories, etc., which can solve the problems of time-consuming, labor-intensive and production efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

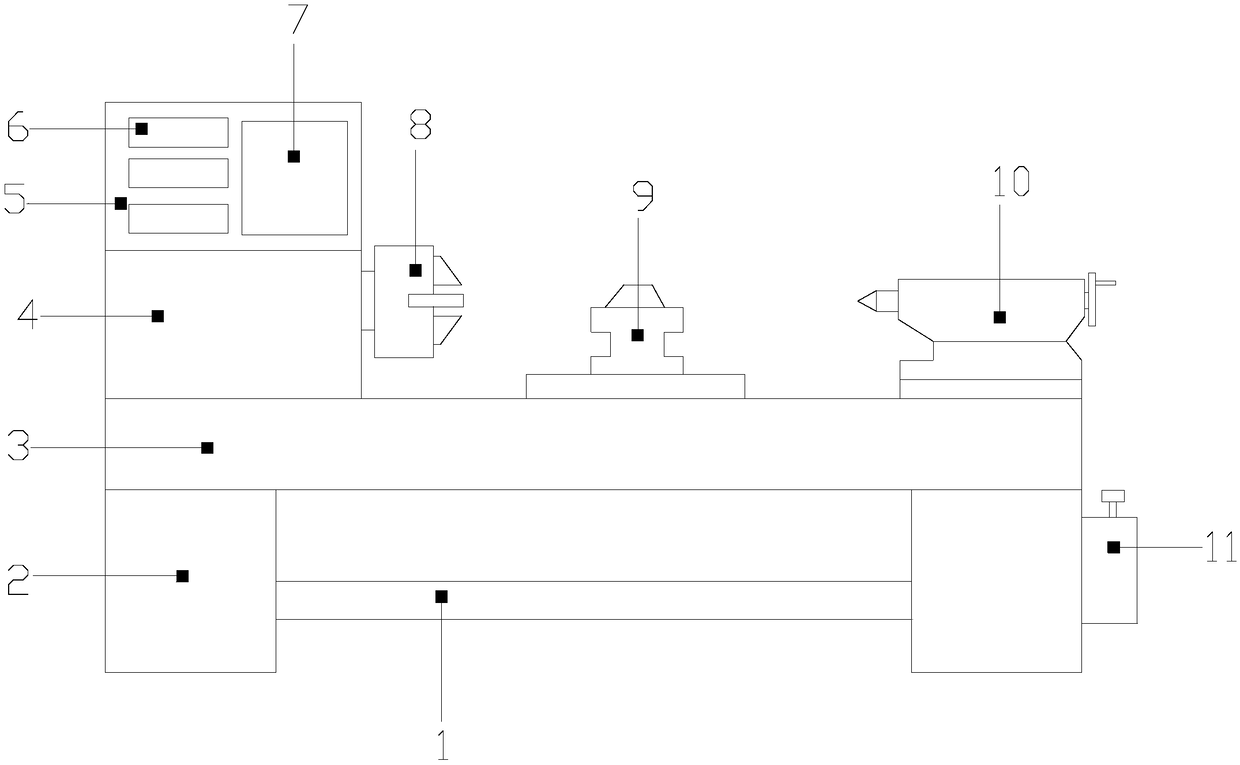

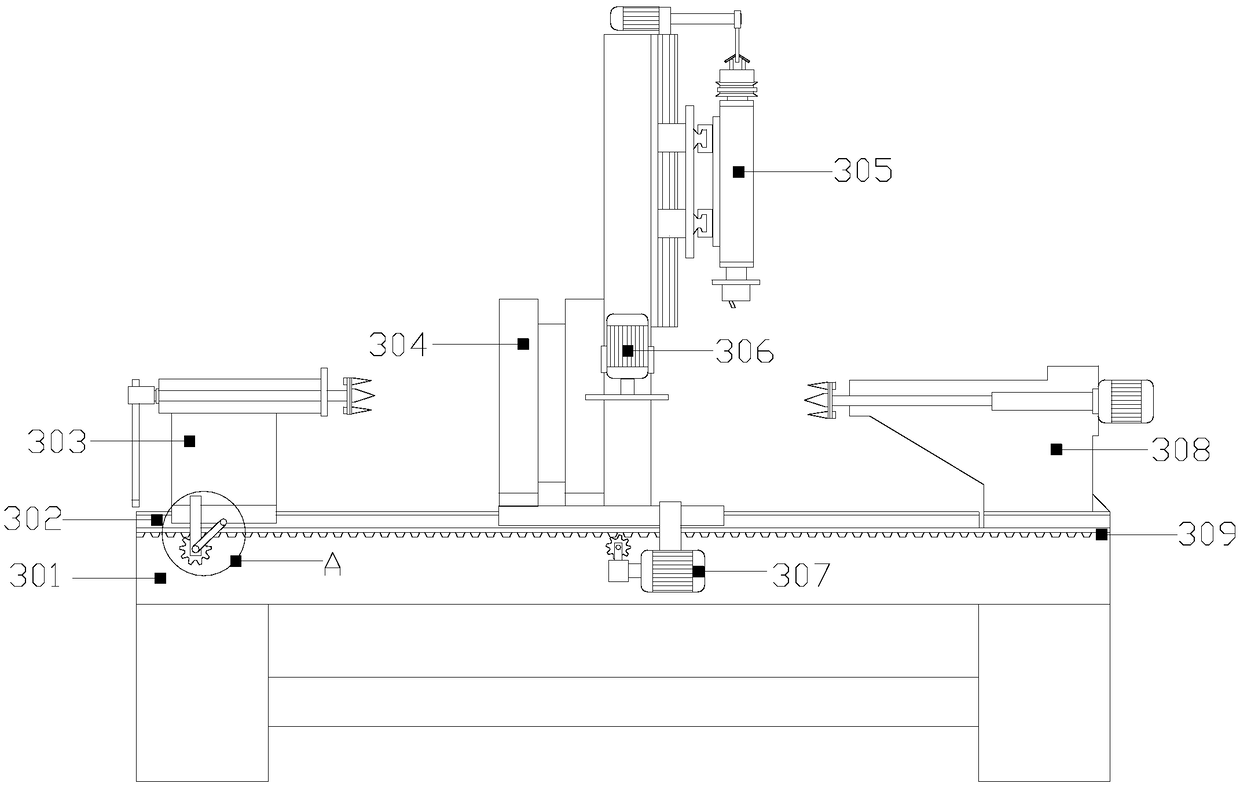

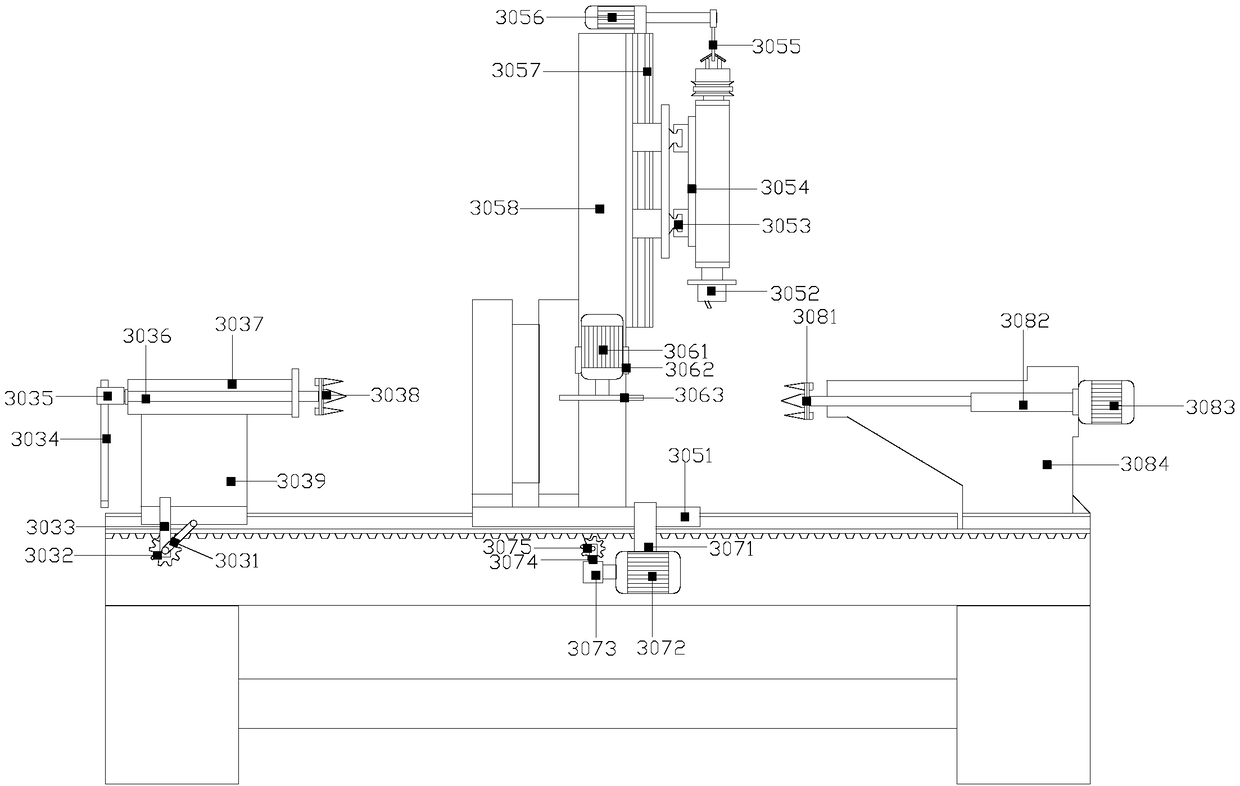

[0022] like Figure 1-Figure 5As shown, the present invention provides a lathe tailstock moving device, the structure of which includes a support rod 1, a fixed bracket 2, an efficient and fast processing mechanism 3, a spindle box 4, a control box 5, a control switch 6, a display 7, and a three-jaw chuck 8. Rotary tool holder 9, tailstock 10, lubrication box 11, the upper ends of the fixed brackets 2 are respectively welded to both sides of the bottom end of the efficient and fast processing mechanism 3, and the two ends of the support rod 1 extend horizontally to the two fixed brackets 2 The inner sides are welded together, the left side of the lubrication box 11 is fixedly welded to the right side of the fixed bracket 2, the spindle box 4 and the control box 5 are both rectangular structures, and the bottom of the spindle box 4 is fixedly welded to the upper end of the efficient and fast processing mechanism 3 On the left side, the control switch 6 is provided with more tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com