a polishing machine

A polishing machine and transmission mechanism technology, applied in the field of polishing machines, can solve the problems of low transmission efficiency, high energy consumption, easy slipping and overloading, etc., and achieve the effects of maintaining stability, large grinding range, and reducing secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

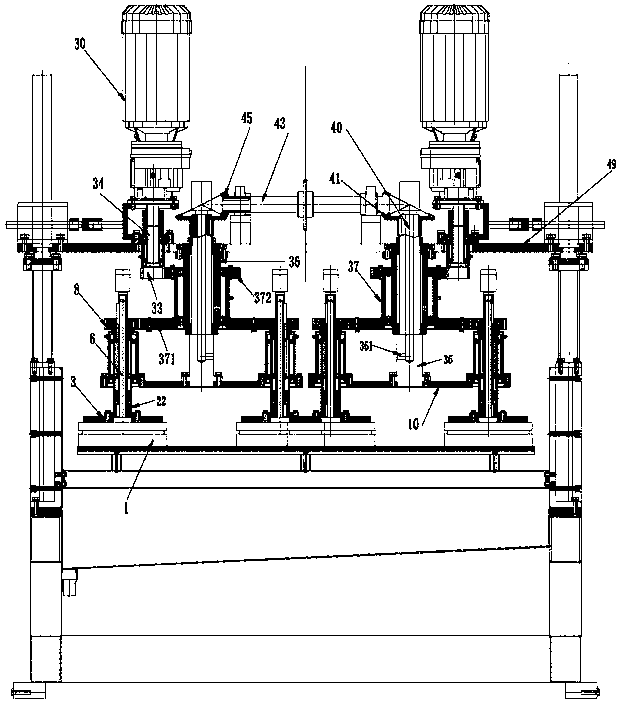

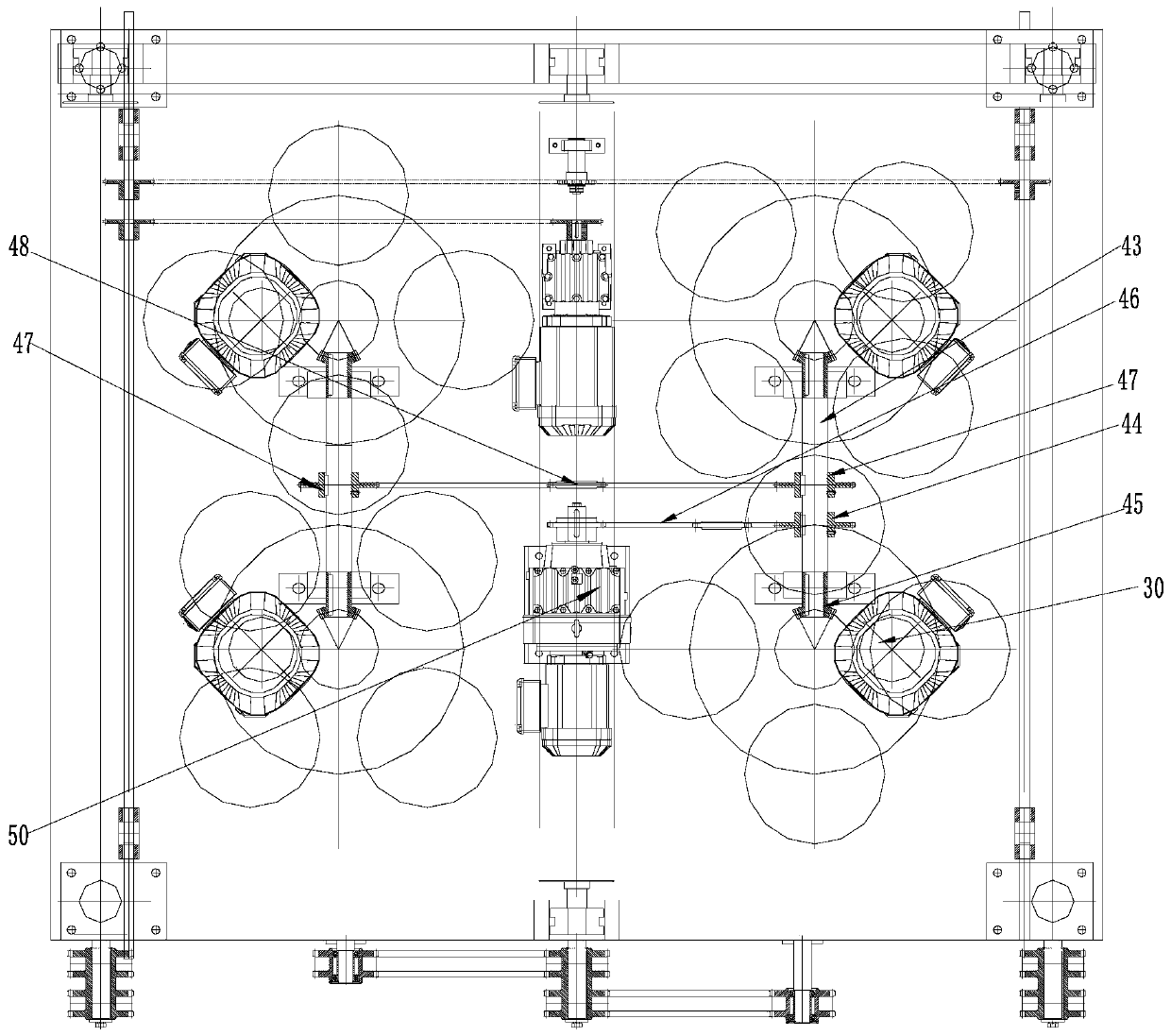

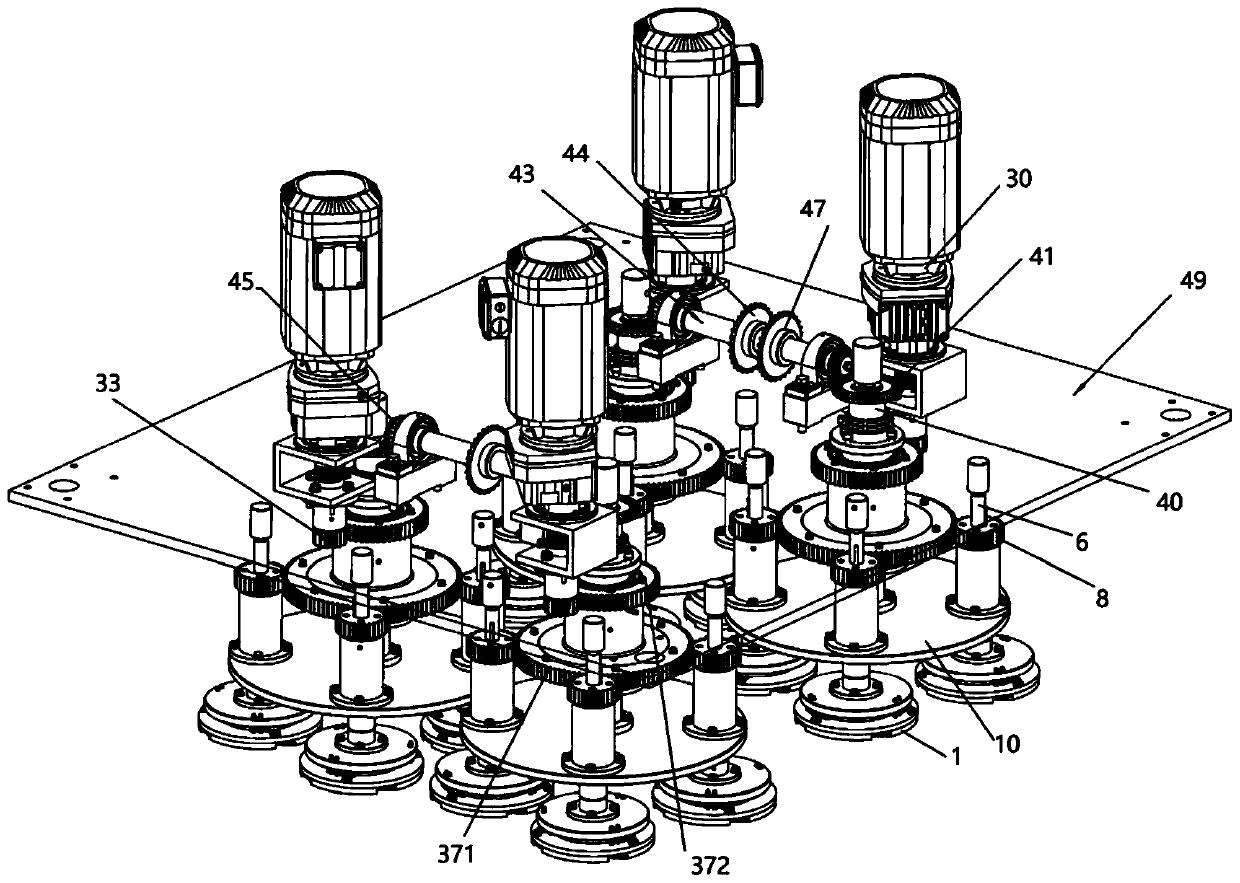

[0032] see Figure 1 to Figure 3 As shown, a polishing machine is installed on a whole frame and includes four groups of grinding head transmission mechanisms installed on a mounting plate 49, each group of grinding head transmission mechanisms includes four grinding head assemblies, and the grinding head The rotation of the assembly includes the rotation of the grinding head and the revolution of the grinding head; each grinding head assembly is evenly fixed on the corresponding mounting plate 10 and divided into upper and lower parts by it, and four grinding head assemblies are evenly arranged around the mounting plate 10 On the bottom of the mounting plate 10 is the working area. Each grinding head assembly includes a transmission shaft 6 that can move up and down and a grinding head 1 driven by the transmission shaft 6 in the working area. The grinding head gear 8 that can drive the transmission shaft 6 to rotate; the grinding head rotation motor 30 is arranged on the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com