Curved glass and molding method thereof

A technology of curved glass and molding method, applied in glass molding, glass remolding, glass production and other directions, can solve the problems of low yield of curved glass molding, optimize appearance quality, reduce residual stress, and avoid pitting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Used to illustrate the beneficial effects of the curved glass of the present invention and its forming method

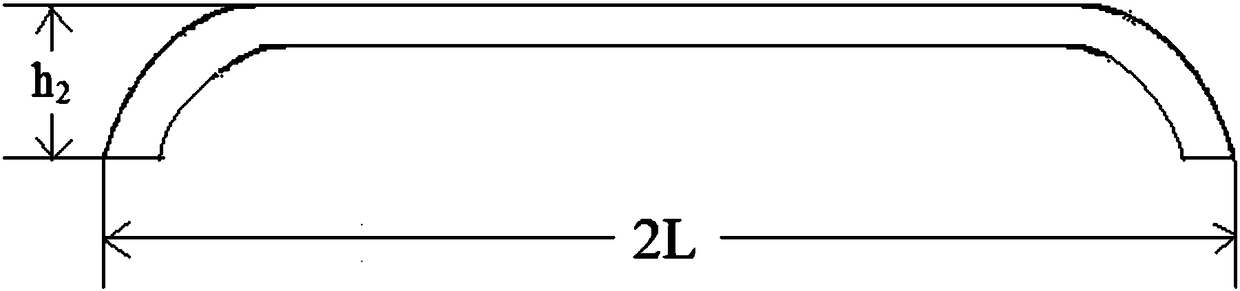

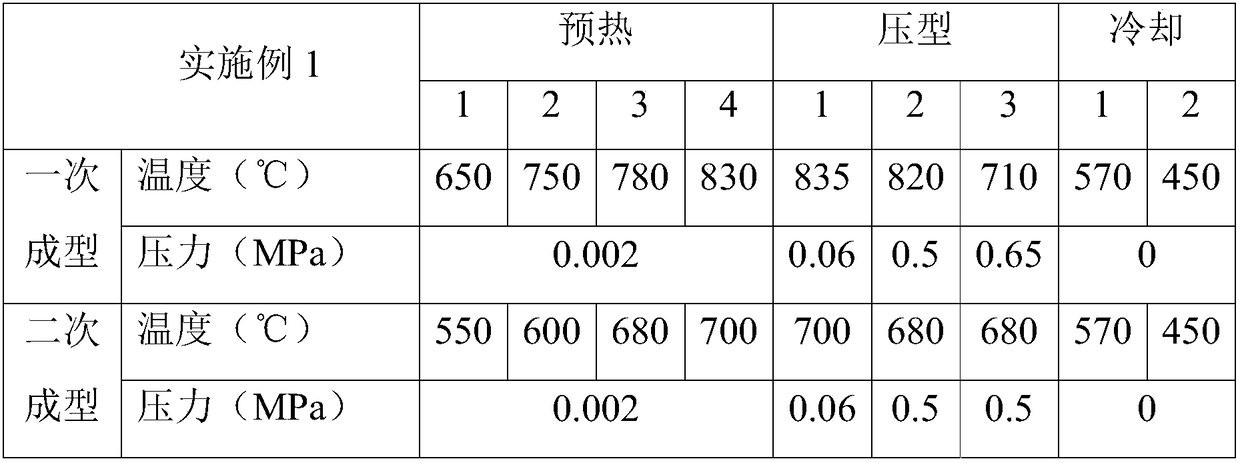

[0031] Take the glass substrate (Corning Gorilla Glass IV, length, width, and thickness: 155*75*0.5mm) and put it into the primary forming mold (the width direction of the glass substrate corresponds to the axial direction of the mold, the same below), and the primary forming mold Put it in the molding furnace, respectively go through four stages of preheating, three stages of molding and two stages of cooling to form a curved glass body. The height of the vertical projection of the curved glass body is h 1 (29.8mm), wherein the process conditions of four-stage preheating, three-stage profiling and two-stage cooling are shown in Table 1, and the residence time of each stage is 60s.

[0032] Take the above-mentioned curved glass blank and put it into the secondary molding mold, put the secondary molding mold in the forming furnace, respectively go through four ...

Embodiment 2

[0037] Used to illustrate the beneficial effects of the curved glass of the present invention and its forming method

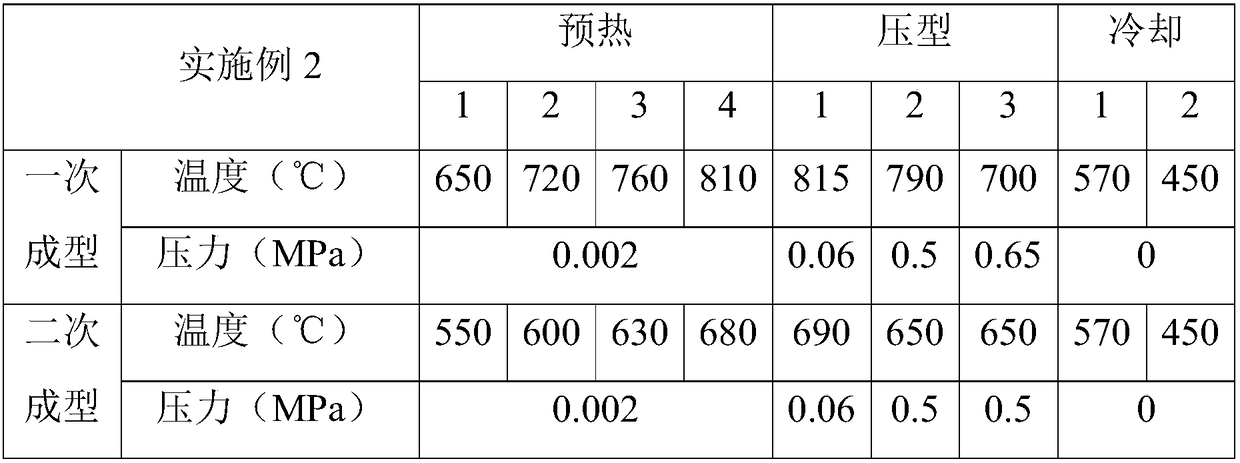

[0038] Take the glass substrate (Corning Gorilla Glass IV, length, width, and thickness: 155*75*0.5mm) and put it into the primary forming mold, put the primary forming mold in the forming furnace, and go through four stages of preheating and three stages of pressing respectively. Type and two-stage cooling to form a curved glass body, the height of the vertical projection of the curved glass body is h1 (21.3mm), wherein the process conditions of four-stage preheating, three-stage pressing and two-stage cooling are shown in Table 2, The duration of each segment is 60s.

[0039] Take the above-mentioned curved glass blank and put it into the secondary molding mold, put the secondary molding mold in the forming furnace, respectively go through four stages of preheating, three stages of molding and two stages of cooling to form a curved glass blank. The height o...

Embodiment 3

[0043] Used to illustrate the beneficial effects of the curved glass of the present invention and its forming method

[0044] Take the glass substrate (Corning Gorilla Glass IV, length, width, and thickness: 155*75*0.5mm) and put it into the primary forming mold, put the primary forming mold in the forming furnace, and go through four stages of preheating and three stages of pressing respectively. Forming and two-stage cooling to form a curved glass blank. The height of the vertical projection of the curved glass blank is h1 (13.7mm). The process conditions of four-stage preheating, three-stage pressing and two-stage cooling are shown in Table 3. The duration of each segment is 60s.

[0045] Take the above-mentioned curved glass blank and put it into the secondary molding mold, put the secondary molding mold in the forming furnace, respectively go through four stages of preheating, three stages of molding and two stages of cooling to form a curved glass blank. The height of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com