Immersion type desulfurization device with mechanical stirring

The technology of a mechanical stirring and desulfurization device is applied in the field of molten iron pretreatment, which can solve the problems of high cost and inconvenient disassembly, and achieve the effects of low cost, convenient replacement and maintenance, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

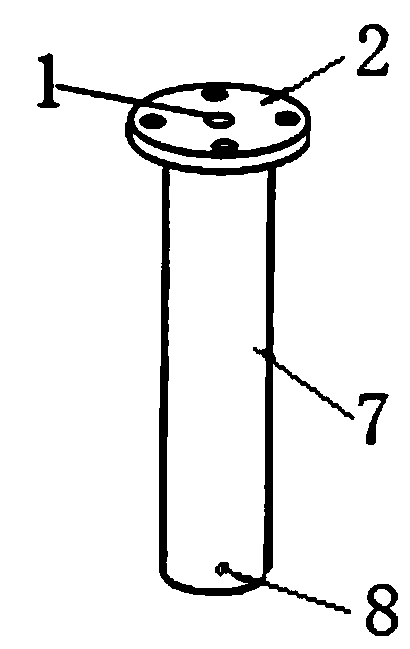

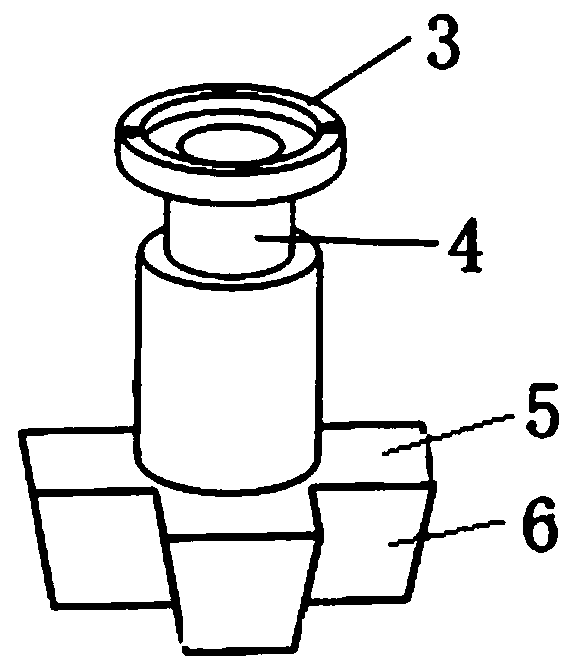

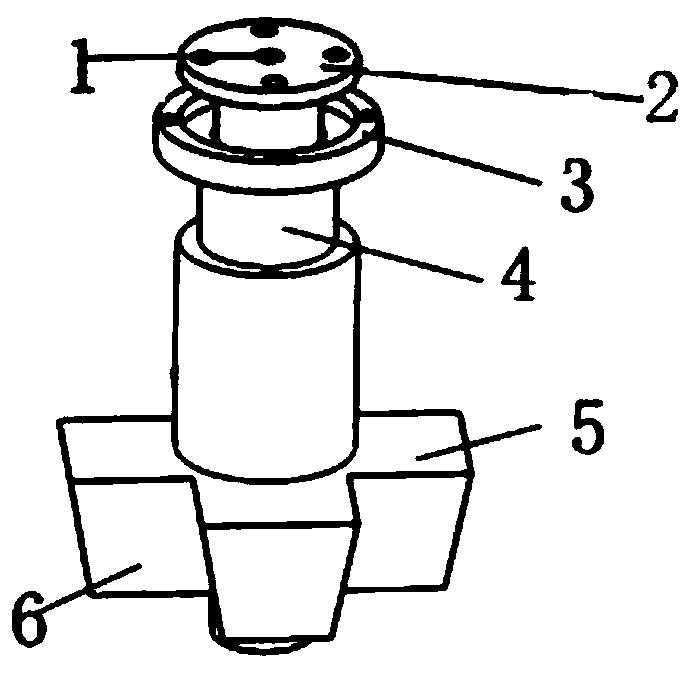

[0039] A submerged desulfurization device with mechanical agitation, including a submerged spray gun and a mechanical agitator. The submerged spray gun is inserted into the hollow in the center of the mechanical agitator, such as figure 1 The immersion spray gun shown includes a spray gun flange connector 2 and a spray gun body 8, and the spray gun flange connector 2 is arranged on the upper end of the spray gun cavity 8, and the spray gun flange connector 2 and the spray gun cavity 8 can be integrally formed, or The inner thread and the outer thread are connected together, and the center of the spray gun flange connector 2 is provided with a powder inlet 1, and the powder inlet 1 is connected to the spray gun body 8, and the center of the spray gun cavity 8 is a cavity, and at the end of the spray gun body 8 A powder outlet 7 is provided, and the spray outlet 7 is located at the lower end of the mechanical agitator, that is, the powder inlet 1 communicates with the spray gun b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com