Underwater explosive cutter component and underwater explosive cutting method

An underwater blasting and cutter technology, which is applied in the fields of engineering blasting and special blasting, can solve the problems of underwater blasting cutting operation efficiency, reduced effect, and increased construction cost, so as to improve practicability and flexibility, reduce construction costs, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

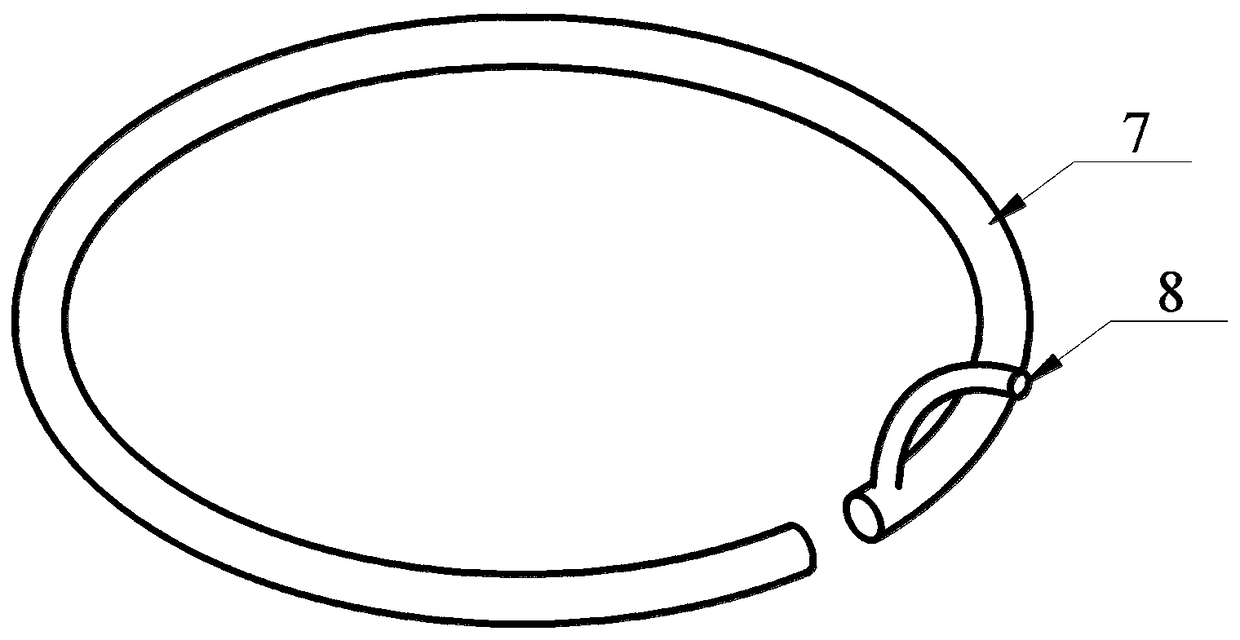

[0028] Embodiment: The underwater explosive cutter assembly of the present invention and its application in the underwater explosive cutting of a cylindrical steel pipe.

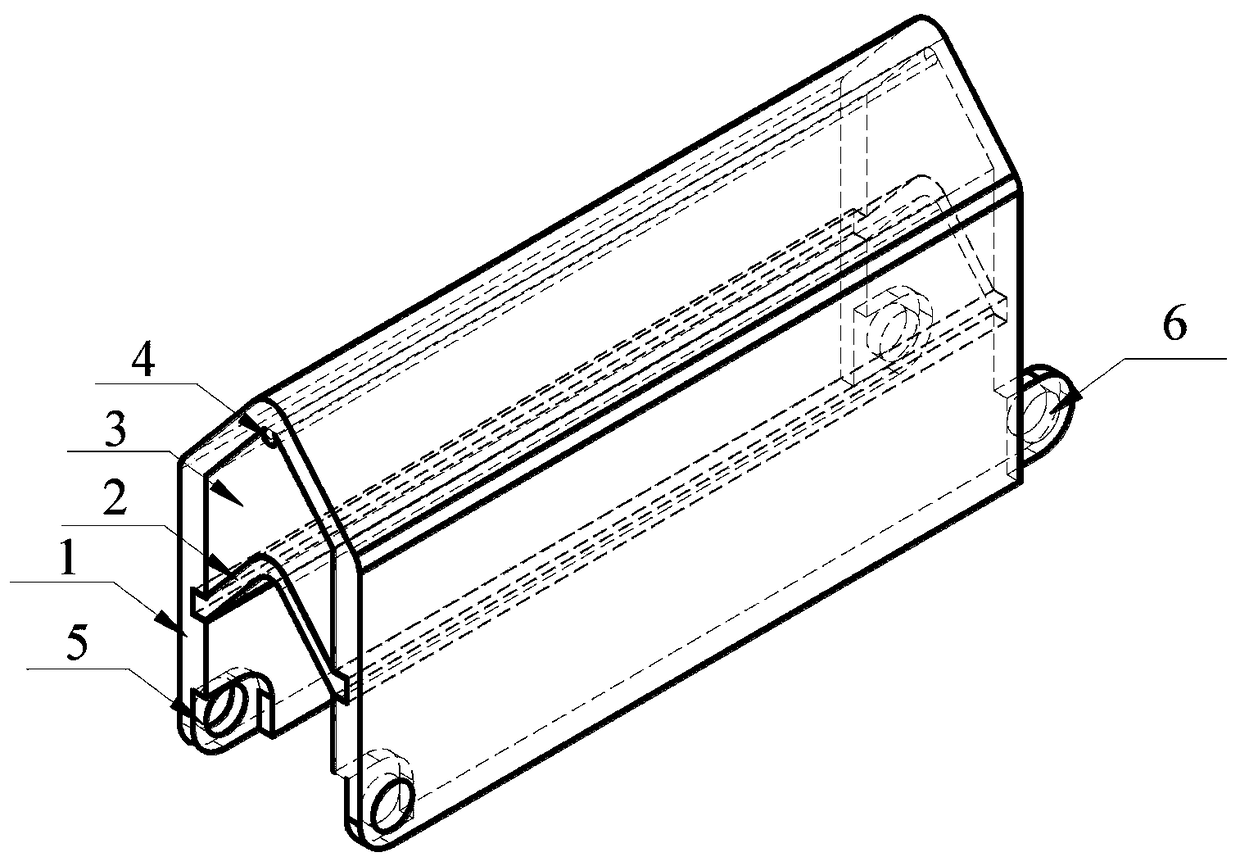

[0029] This embodiment takes the underwater explosive cutting of a cylindrical steel pipe as an example. Cylindrical steel pipes are mostly used in underwater drilling platforms, steel structure bridges, etc., and they need to be dismantled because the oil life reaches the design life. In this example, the cut steel pipe 12 has an outer diameter of 300 mm and a wall thickness of 10 mm. The steel pipe is located underwater and needs to be cut by underwater explosion. According to the outer diameter of the steel pipe, 10 explosive cutters with a length of 10 cm are selected.

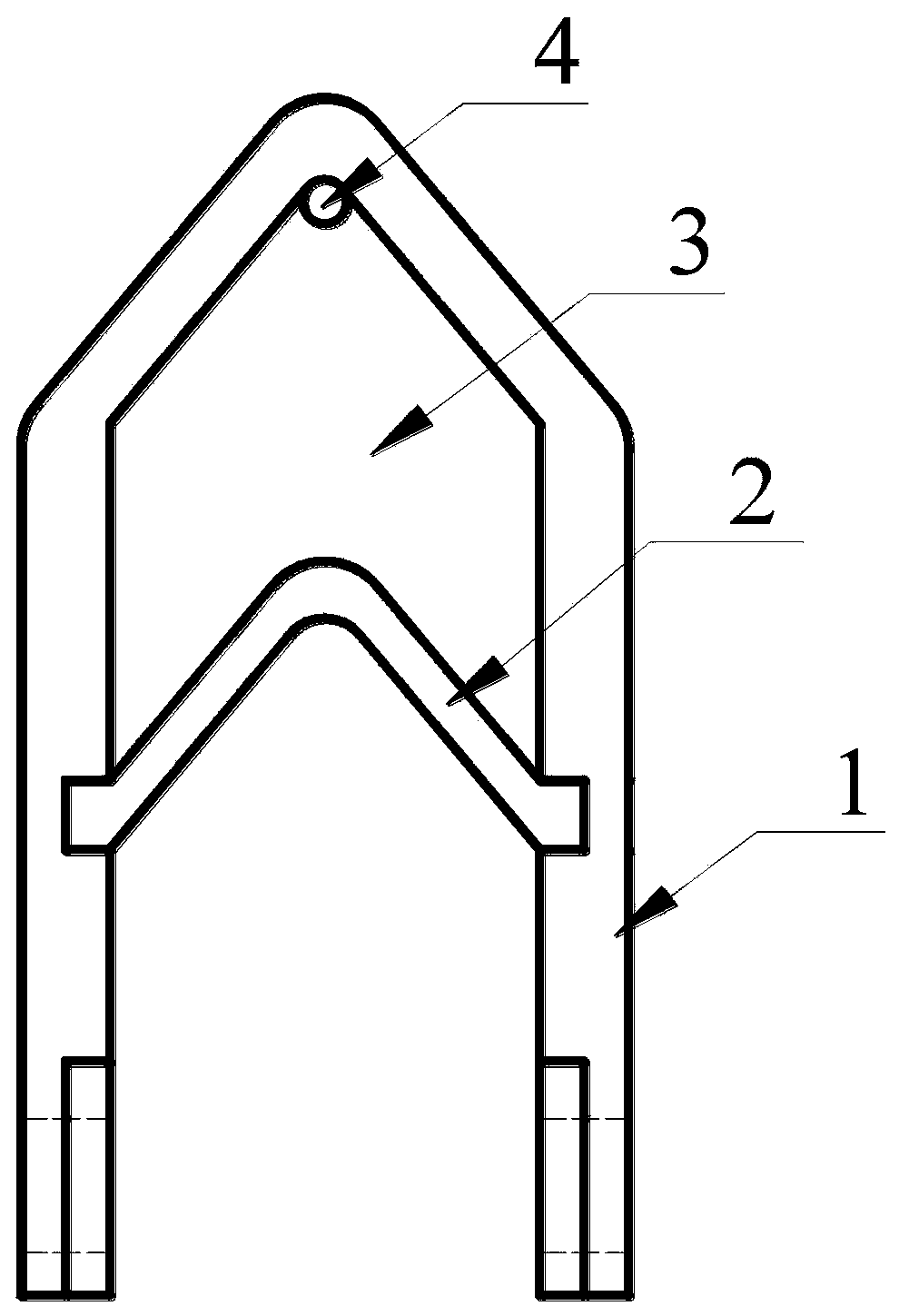

[0030] The explosive cutter is composed of a cutter shell 1, a metal energy-concentrating cover 2, and a high-energy explosive 3. The cutter shell 1 is a cross-section profile shaped like a door, and the top of the metal shell's cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com