Concrete rebound instrument based on annular spring

A ring-shaped spring and concrete technology, applied in instruments, scientific instruments, testing material hardness, etc., can solve the problems of unfavorable realization, inconvenient operation, large size of external auxiliary facilities, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

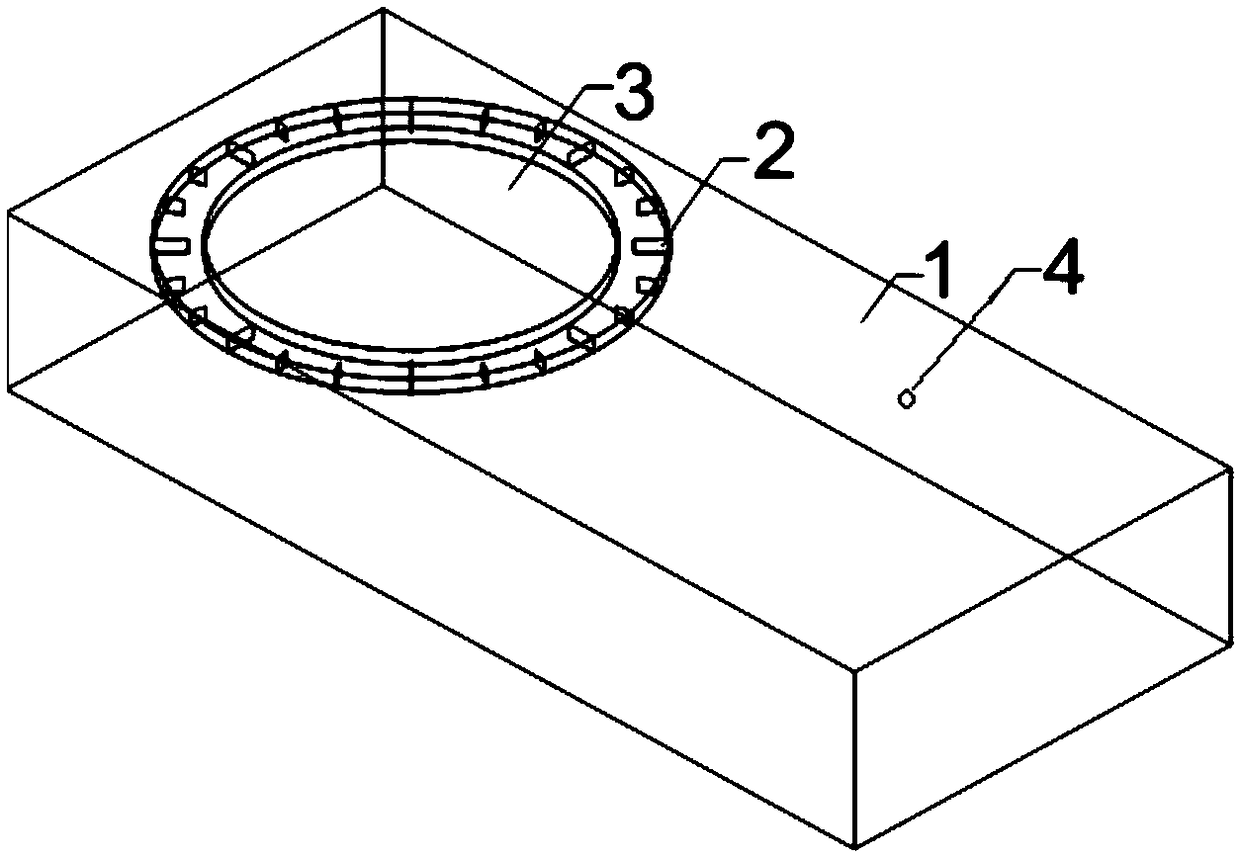

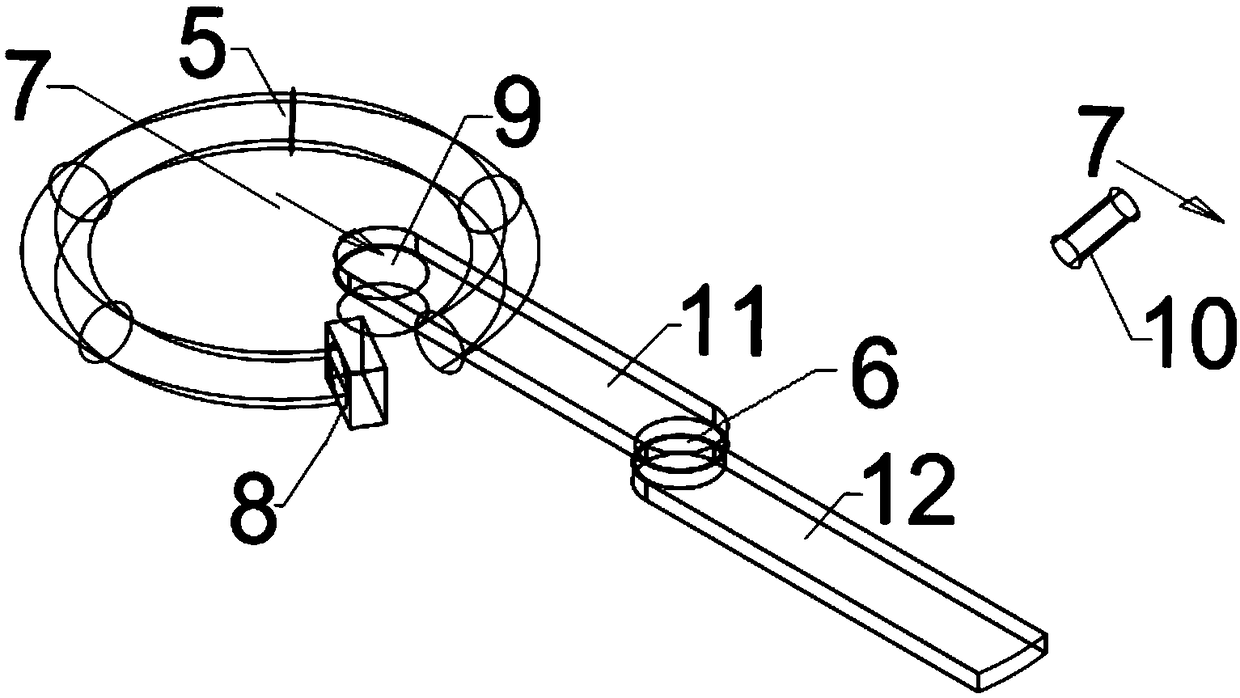

[0020] The present invention is designed as Figure 1-Figure 4 As shown, a concrete hammer device based on a ring spring provided by the patent of the present invention includes a casing 1, a dial 2, a ring spring 5, a double-link device and ancillary components. A casing limit pin hole 4 is arranged on the top of the casing 1, and a reading pointer 7 is arranged on the plane of the ring spring 5 .

[0021] Wherein, in practical application, the ring spring 5 is a circular ring with a notch, and a shock-absorbing elastic washer 8 is provided on the side of the notch.

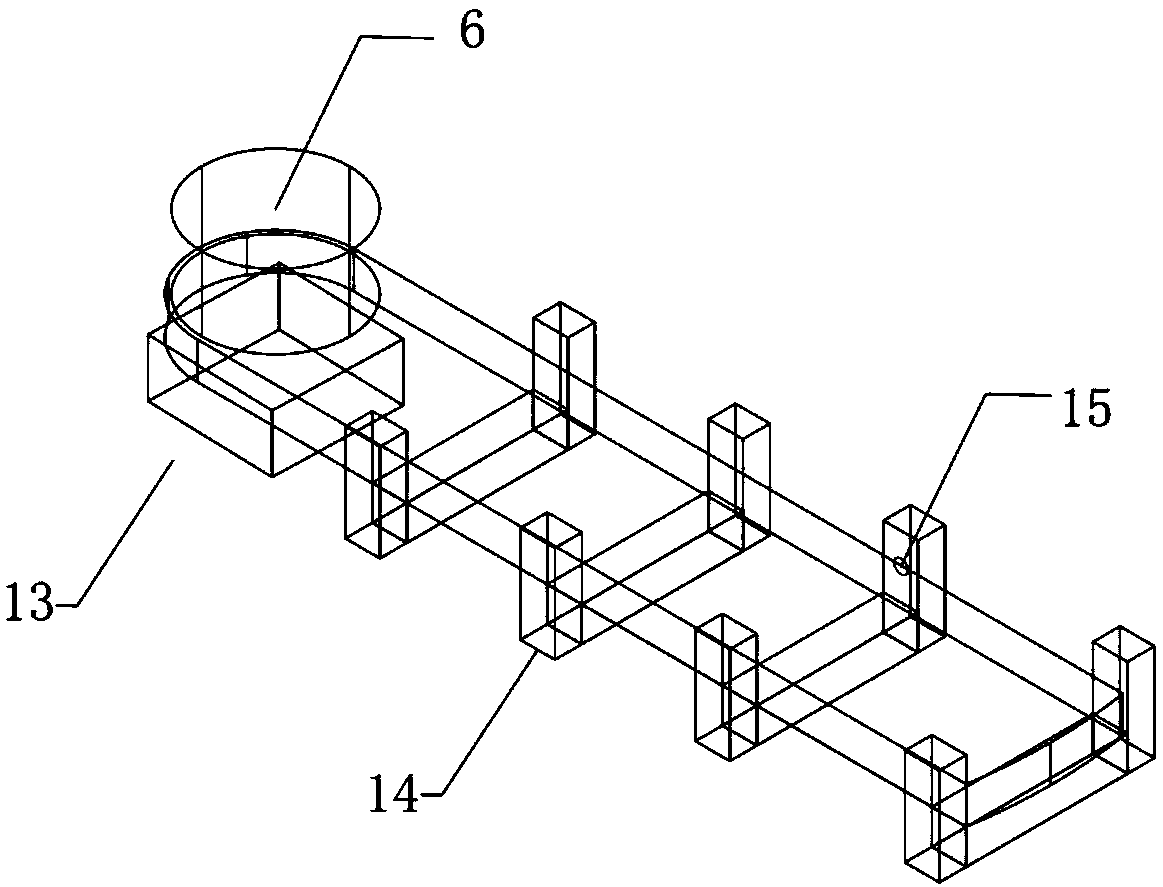

[0022] Wherein, in practical application, the double linkage device includes a metal linkage 11 , a strike lever 12 and a rotating shaft 9 . One end of the metal connecting rod 11 is hinged on one side of the notch of the annular spring 5 through the first rotating shaft 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com