A method for statistic analysis of fatigue life of titanium alloy formed by laser deposition

A fatigue life and laser deposition technology, used in manufacturing computing systems, complex mathematical operations, and process efficiency improvement, can solve problems such as poor powder melting, inaccurate description of fatigue life distribution characteristics, and large fatigue dispersion. estimated effect

Active Publication Date: 2019-01-15

BEIHANG UNIV

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] Experiments and theoretical studies show that the laser deposition molding process is completely different from the traditional mechanical processing method. Its unique process characteristics make the material / structure will be affected by more factors during the molding process, making it inevitable that there will be pores inside the material / structure. Defects such as poor powder melting

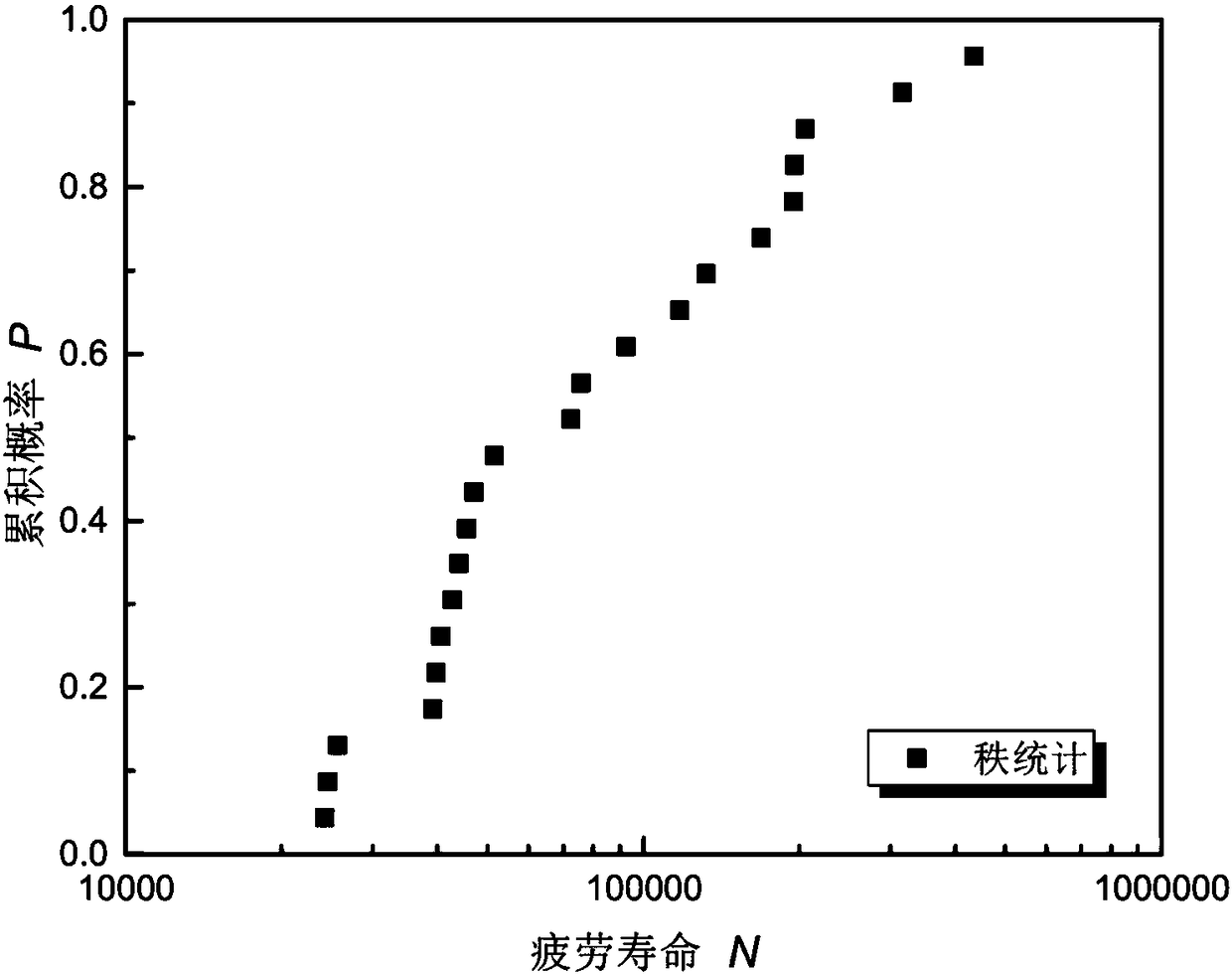

These defects are randomly distributed inside the part. Under the action of alternating loads, laser deposition molding materials will have different failure characteristics from traditional materials. Compared with the single fatigue failure mode of traditional mature process materials, laser deposition molding titanium alloy materials will appear two There are two main failure modes: one is the same failure mode as that of traditional materials, and the other is the failure mode caused by cracks induced by defects; the corresponding material life of these two failure modes is different, resulting in a larger failure mode than traditional materials. The statistical analysis of the fatigue life of laser deposition formed titanium alloy materials is a key technical problem that needs to be solved urgently.

The test results show that it is difficult to accurately describe the fatigue life distribution of metal materials formed by laser deposition using the lognormal distribution model recommended in GB / T 24176 and ISO 12107, which will lead to inaccurate description of the fatigue life distribution characteristics, which in turn will cause characteristic parameters The estimation is inaccurate, the reliable life is too low and the actual situation does not match

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

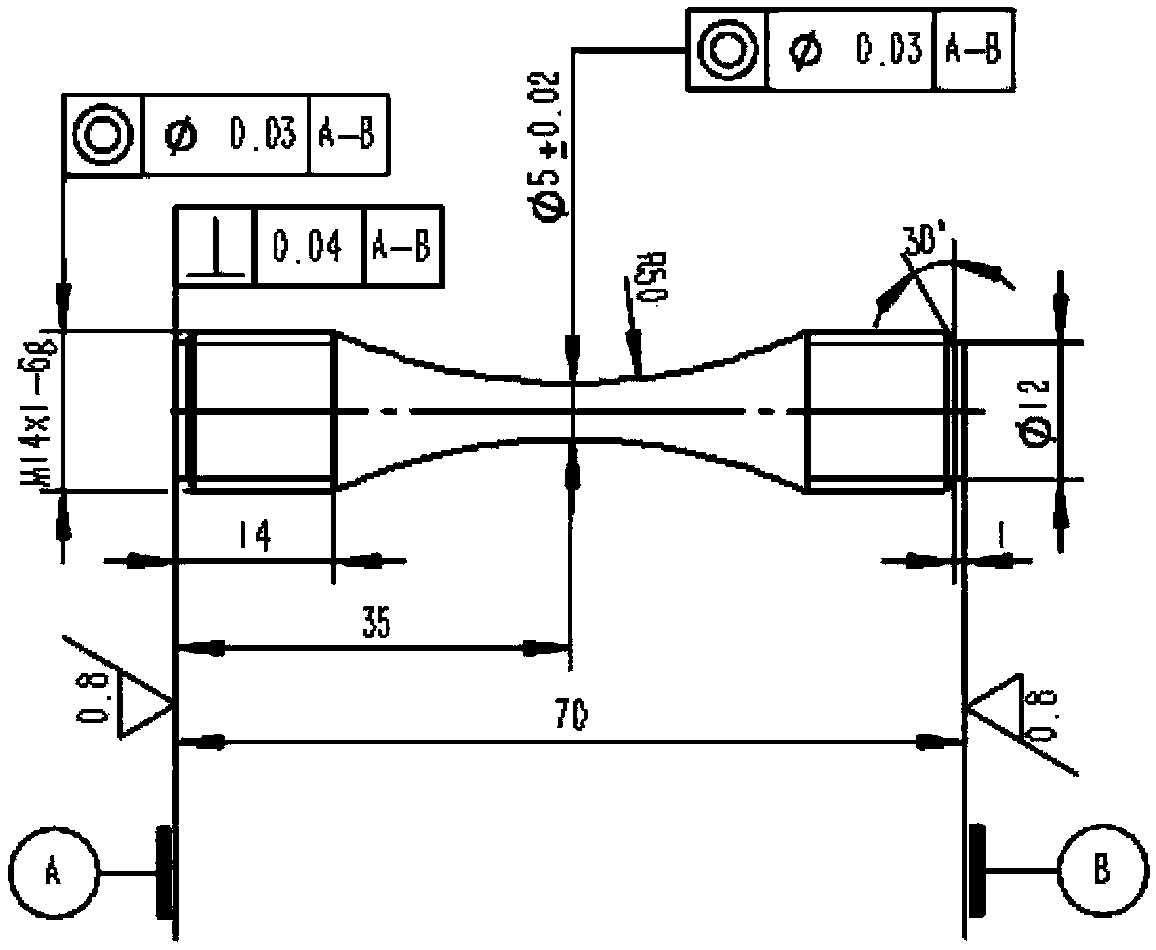

[0072] Step 1: Acquisition of fatigue life data.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

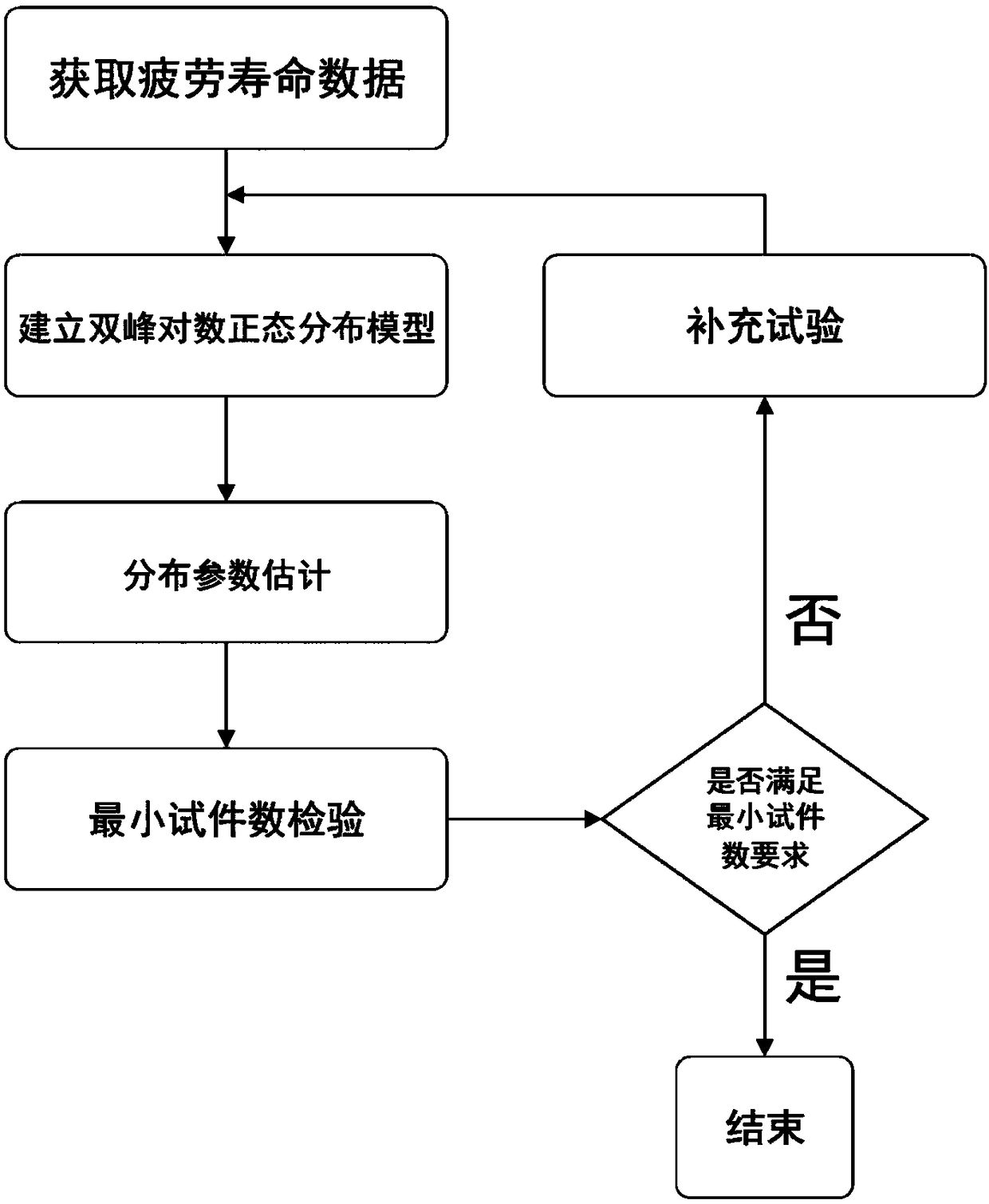

A method for statistically processing the fatigue life of titanium alloy formed by laser deposition is characterized in that a bimodal lognormal distribution model is adopted to describe the fatigue life of a titanium alloy specimen formed by laser deposition, and a maximum likelihood method and a rank statistics minimum distribution function residual sum of squares (SSE) method are adopted to estimate distribution parameters. Specifically, the method includes: acquiring fatigue life data; establishing the bimodal lognormal distribution model; performing distributed parameter estimation basedon the maximum likelihood estimation and minimum SSE; performing test with a minimum number of test pieces. The application of the invention can more accurately describe the dispersion characteristicsof the fatigue life of the laser deposition molded titanium alloy specimen, and more accurately obtain the characteristic parameters of the fatigue life of the laser deposition molded titanium alloy.

Description

technical field [0001] The invention relates to a statistical analysis technology for the fatigue life of metal materials, in particular to a statistical analysis method for the fatigue life of titanium alloy materials formed by laser deposition. Background technique [0002] Fatigue fracture under alternating load is the main failure mode of the structure. In order to ensure the safety and economy of the structure, modern advanced mechanical structures are designed with anti-fatigue design ideas. According to this design idea, materials with good fatigue resistance should be used in the structural design stage. Therefore, it is necessary to carry out fatigue performance testing and characterization of materials. A large number of theoretical and experimental studies have shown that the fatigue life of materials has obvious dispersion, that is, the same batch of test pieces obtained by the same material technology and test piece processing technology, the fatigue life of di...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/18

CPCG06F17/18Y02P90/30

Inventor 贺小帆王天帅湛伟刚王晓波

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com