A Self-Induction Piezoelectric Drive Circuit Based on Feedforward Adaptive Compensation

An adaptive compensation and drive circuit technology, applied in the field of measurement and control, can solve problems such as piezoelectric equivalent capacitance mismatch, induced voltage measurement error, etc., and achieve the effect of eliminating bridge imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

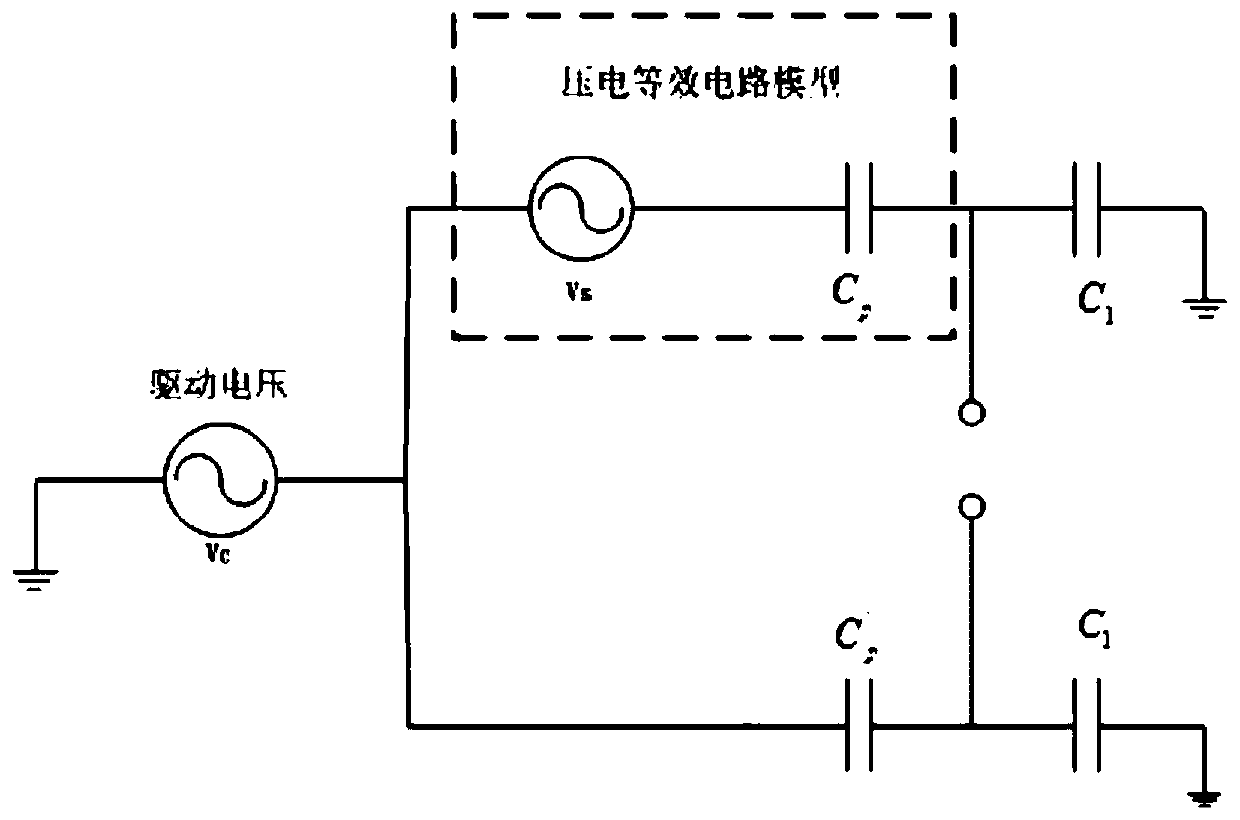

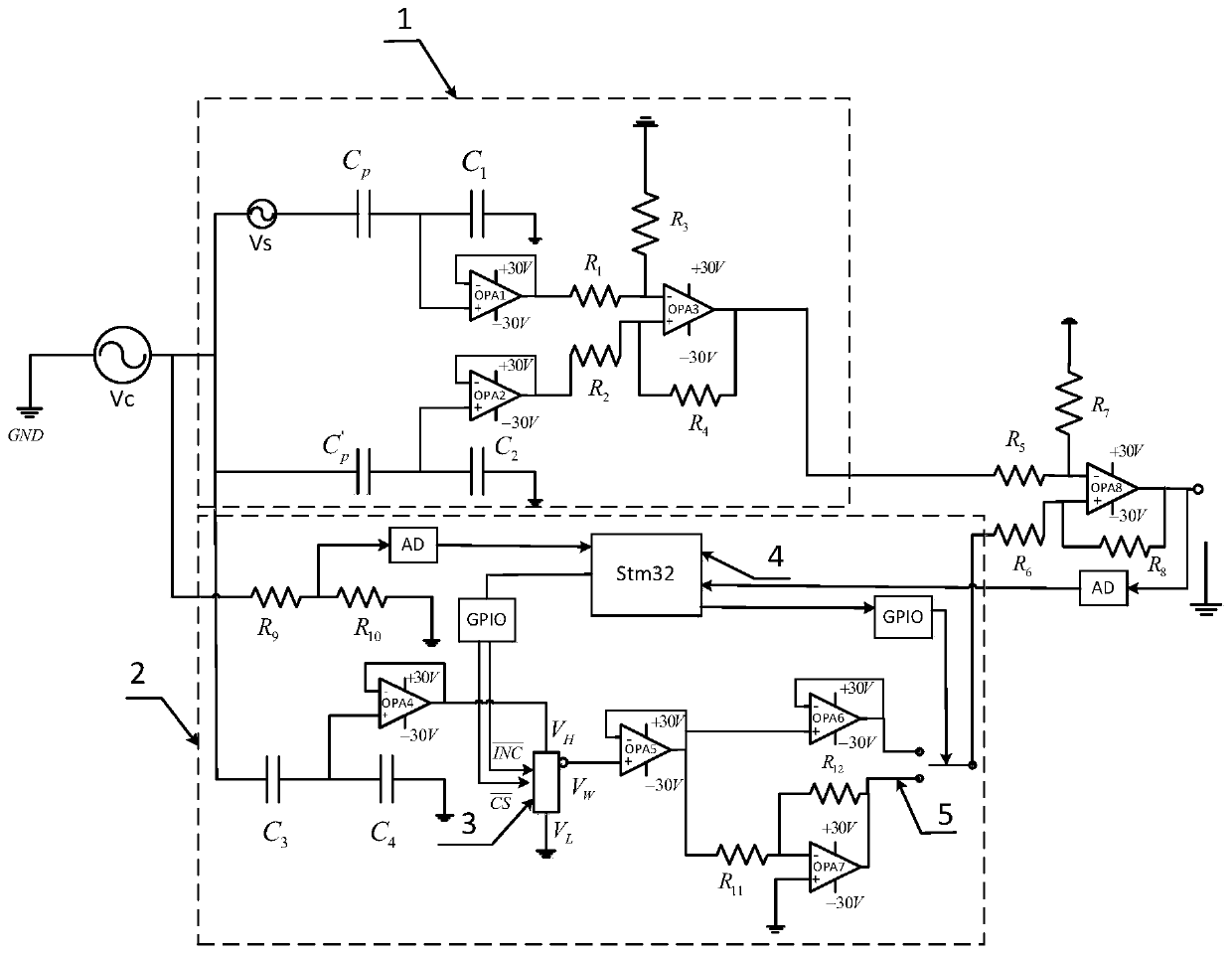

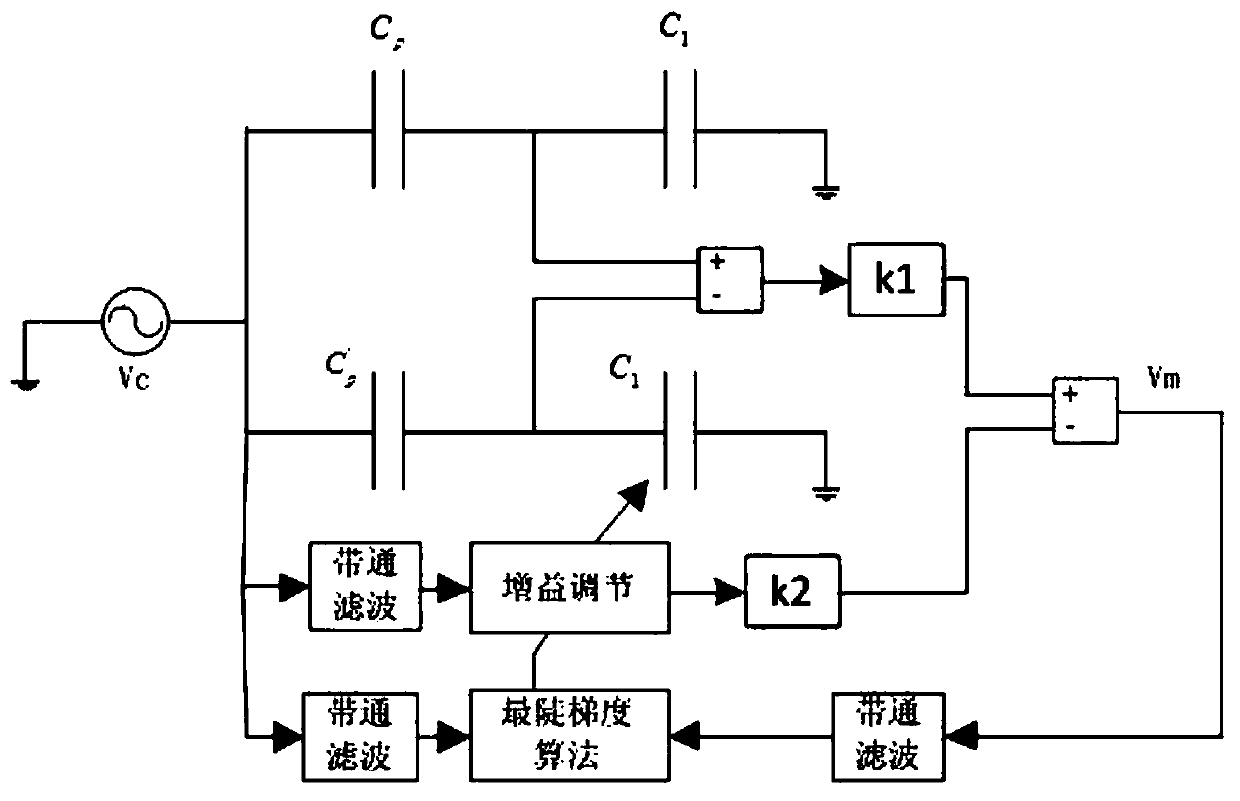

[0014] Such as figure 2 Shown, a self-induction piezoelectric drive circuit based on feedforward adaptive compensation, including: piezoelectric self-induction module 1, feedforward module 2, digital potentiometer 3, digital controller 4 and relay switch 5; piezoelectric self-induction Module 1 extracts the piezoelectric induction signal through the bridge circuit, and then applies it to the measurement output through one end of the subtraction circuit; the other end of the subtraction circuit uses the feedforward compensation module 2 to correct the induction signal caused by the imbalance of the bridge arm The measurement error is compensated; the compensation voltage is drawn from the drive voltage terminal, and applied to the digital potential 3 through the voltage follower after the voltage division capacitor and voltage division. Using the adjustable gain characteristic of the digital potentiometer, the amplitude gain of the compensation voltage is determined by the digi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com