Auto-focusing debug method, device, apparatus and storage medium

A technology of automatic focusing and debugging method, applied in the optical field, can solve problems such as long debugging time, and achieve the effect of shortening time, improving debugging efficiency, and fast and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

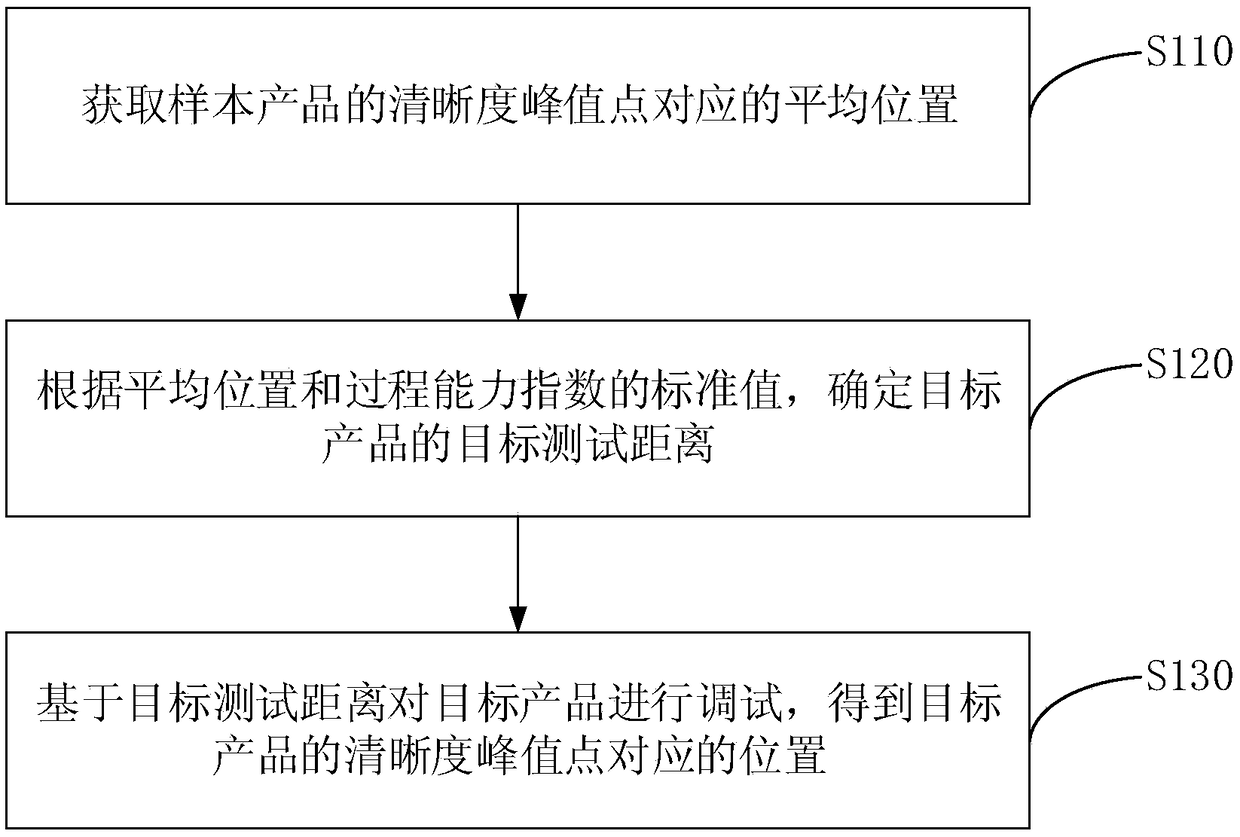

[0027] figure 1 It is a flowchart of the auto-focus debugging method in Embodiment 1 of the present invention. This embodiment is applicable to the situation of realizing auto-focus debugging. The method can be executed by an auto-focus debugging device, which can adopt software and / or hardware Realize, for example, that the means may be configured in a device. In this embodiment, the autofocus debugging of the camera module is taken as an example for description. The method may specifically include:

[0028] S110. Obtain an average position corresponding to the sharpness peak point of the sample product.

[0029] Wherein, the sample product may be a product requiring auto-focus, and the specific type is not limited in this embodiment, for example, it may be a camera module. The specific number of sample products is not limited, and in this embodiment may be at least 2000, the more the better. The sharpness peak point is the highest sharpness of the image obtained by using...

Embodiment 2

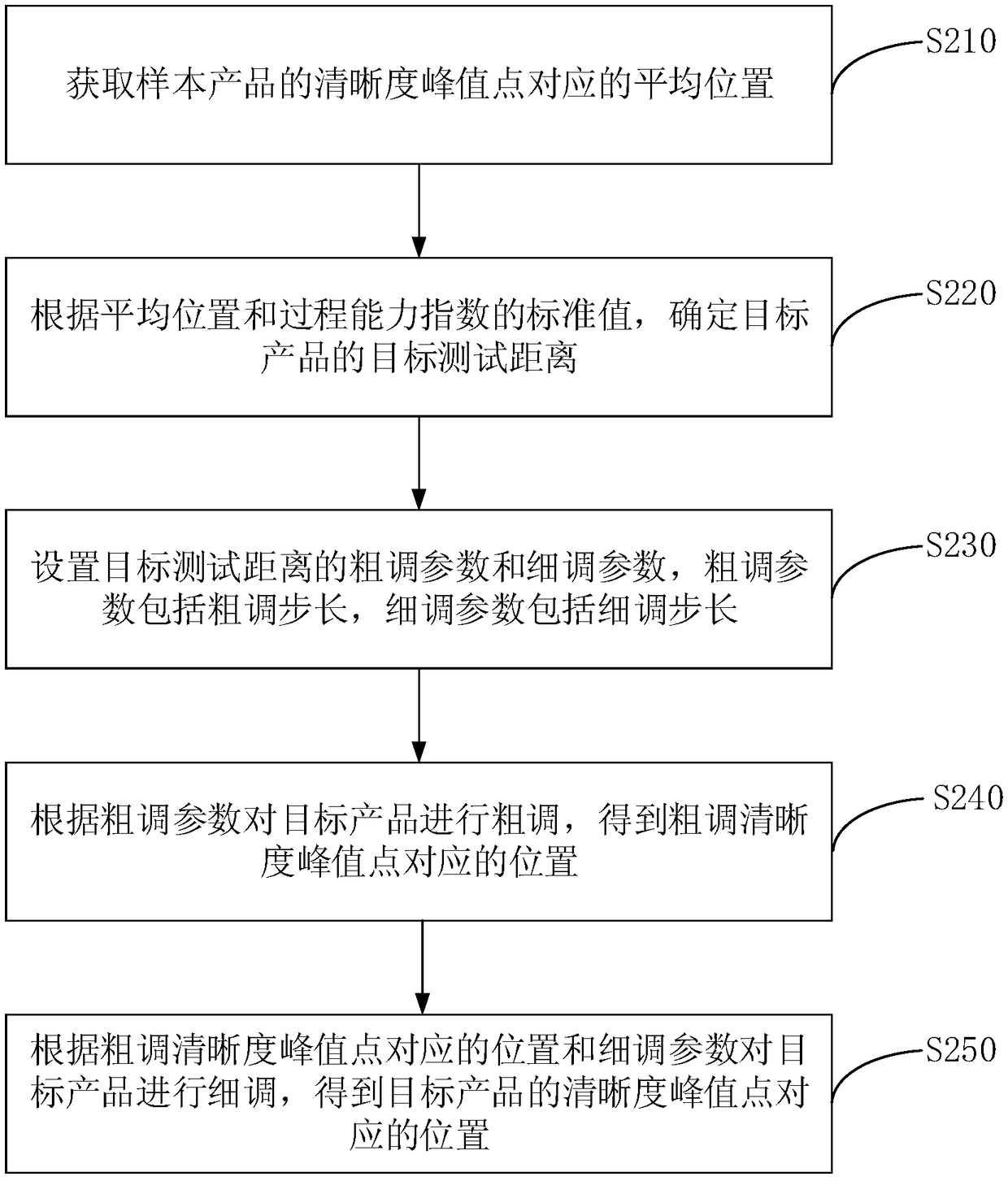

[0044] figure 2 It is a flow chart of the auto-focus debugging method in Embodiment 2 of the present invention. On the basis of the foregoing embodiments, this embodiment further optimizes the foregoing autofocus debugging method. Correspondingly, the method in this embodiment specifically includes:

[0045] S210. Obtain an average position corresponding to the sharpness peak point of the sample product.

[0046] Optionally, obtaining the average position corresponding to the sharpness peak point of the sample product includes: debugging each sample product based on the complete test distance of the sample product to obtain the position corresponding to the sharpness peak point of each sample product; The position corresponding to the degree peak point is obtained to obtain the average position.

[0047] S220. Determine a target test distance of the target product according to the average position and the standard value of the process capability index.

[0048] Optionally...

Embodiment 3

[0062] Figure 5 It is a schematic structural diagram of the auto-focus debugging device in Embodiment 3 of the present invention, and this embodiment is applicable to the situation of realizing auto-focus debugging. The auto-focus debugging device provided in the embodiment of the present invention can execute the auto-focus debugging method provided in any embodiment of the present invention, and has corresponding functional modules and beneficial effects for executing the method. The device specifically includes an average module 310, a distance module 320 and a debugging module 330, wherein:

[0063] An average module 310, configured to obtain the average position corresponding to the sharpness peak point of the sample product;

[0064] The distance module 320 is used to determine the target test distance of the target product according to the average position and the standard value of the process capability index;

[0065] The debugging module 330 is configured to debug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com