All-directional sprinkling irrigation device for agricultural hydraulic engineering

A technology of water conservancy projects and sprinkler irrigation devices, applied in watering devices, agriculture, applications, etc., can solve problems such as limited sprinkler irrigation areas, achieve complete irrigation, realize spraying range, and be beneficial to growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

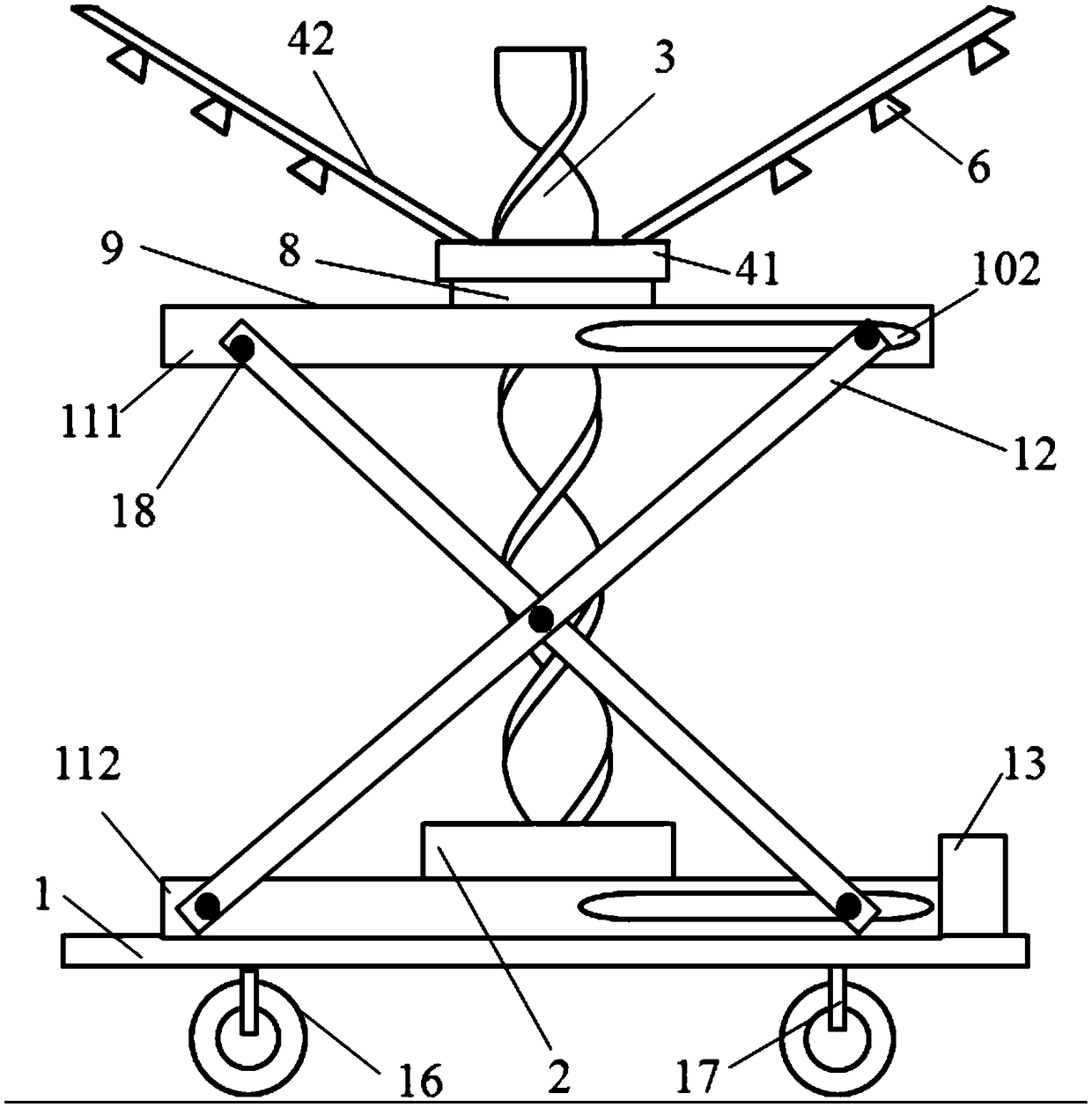

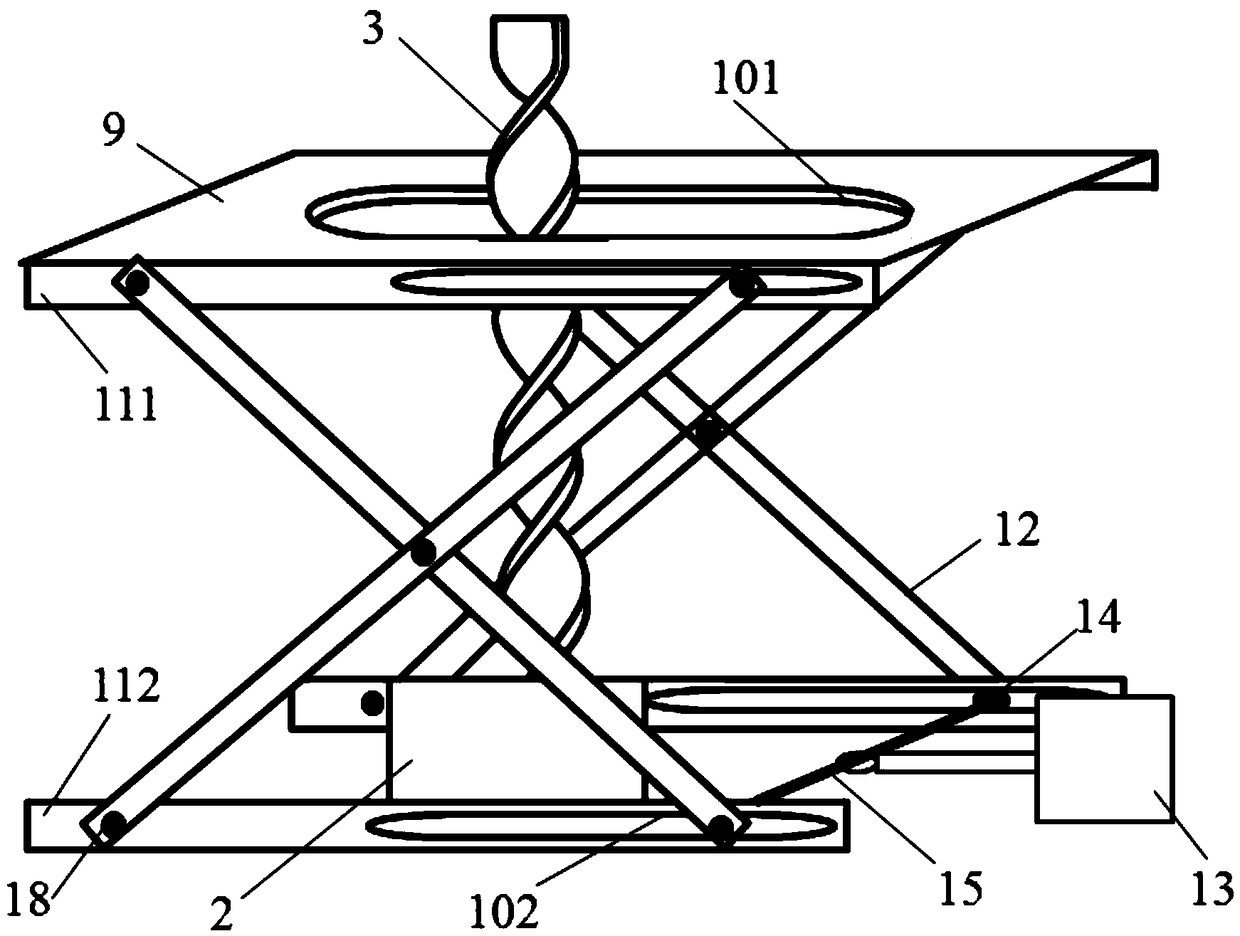

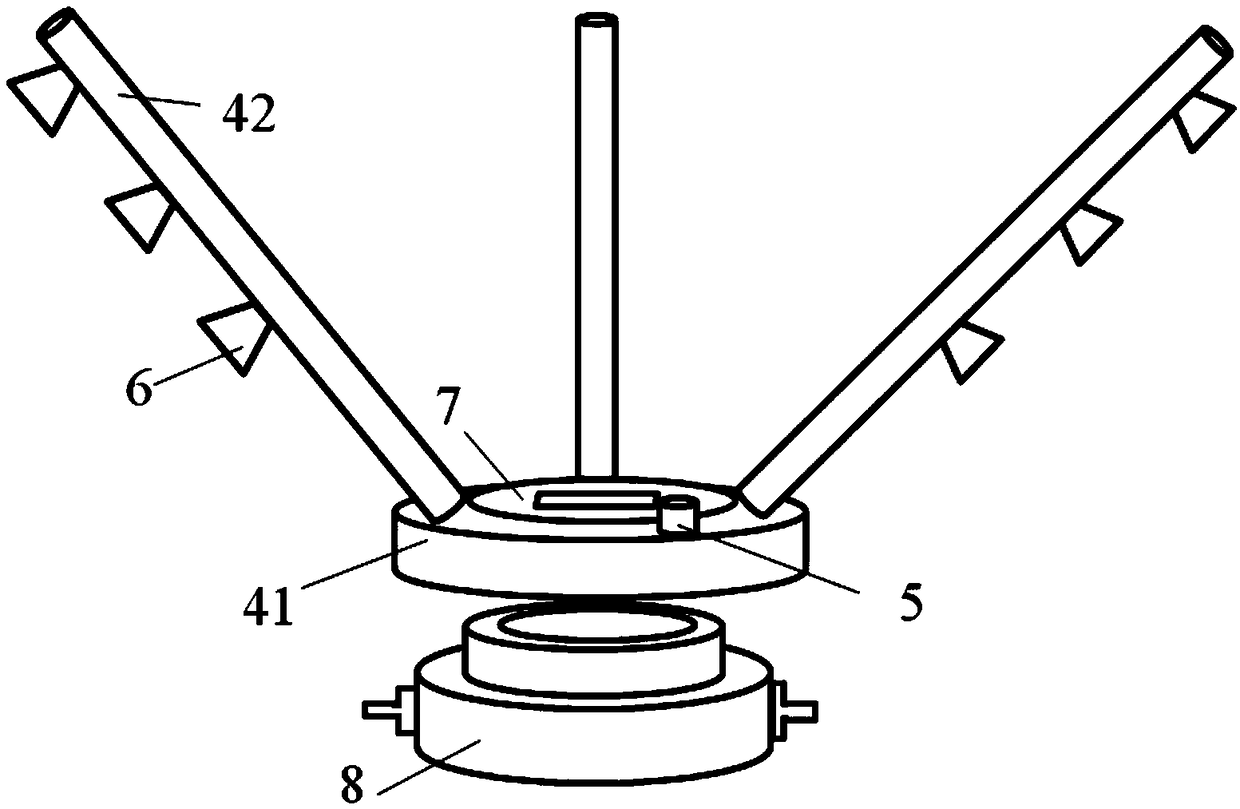

[0017] An all-round sprinkler irrigation device for agricultural water conservancy projects, see Figure 1-4 , including base plate 1, base plate 1 is provided with oil cylinder 13 and base 2, base 2 is vertically provided with twist rod 3, base plate 1 is also provided with upper bracket 111 and lower bracket 112, between upper bracket 111 and lower bracket 112 A support rod 12 is provided, and the two support rods 12 are hinged to each other. The two ends of the support rod 12 are respectively connected with the two sides of the upper bracket 111 and the lower bracket 112. The upper bracket 111 includes a support plate 9, and the support plate 9 is provided with Slide rail Ⅰ101, slide rail Ⅰ101 is provided with a sliding seated bearing 8, on which a twisted rod nut 7 is arranged, the small hole on the twisted rod nut 7 matches the twisted rod 3, and the twisted rod nut 7 and the seated The bearing 8 is threaded on the twist rod 3, the outer wall of the twist rod nut 7 is fix...

Embodiment 2

[0023] First, the sprayer is put through the small hole on the twist rod nut 7 on the twist rod 3, so that the lower end of the twist rod nut 7 is in close contact with the upper end of the bearing with seat 8. When all-round irrigation is required, move the device to the place where irrigation is required, open the oil cylinder 13, so that the oil cylinder 13 drives the connecting rod 15 to move backward, the slider 14 slides backward in the slide rail II 102, and the support rod 12 and the lower bracket 112 The angle between them increases, and at the same time drives the support plate 9 to move upward. Since the twist rod 3 is fixed, the center of the support plate 9 will move during the rising process, and the bearing with seat 8 will slide in the slide rail I101, and at the same time push the sprinkler. Make the sprinkler rotate clockwise or counterclockwise along the twisted pattern on the twist rod 3 along the small hole on the twist rod nut 7, so that the spray head 6 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com