Evaporation apparatus and evaporation method adopting active carbon fiber plate as evaporation plate

A technology of activated carbon fiber and evaporation device, which is applied to evaporator accessories, horizontal tube evaporators, etc., can solve the problems of small evaporation surface, easy failure of movable parts, and easy scaling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing, but not a kind of limitation;

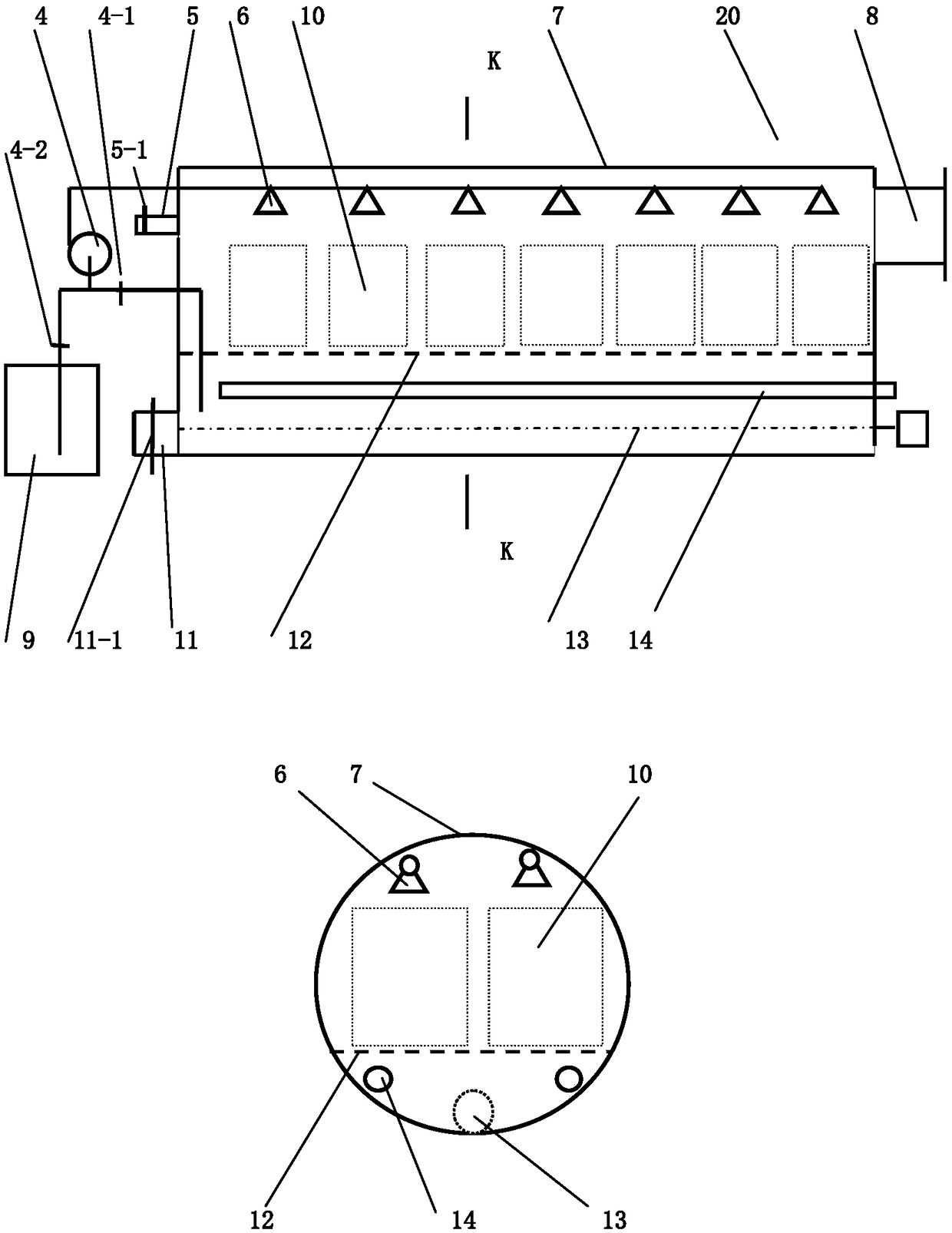

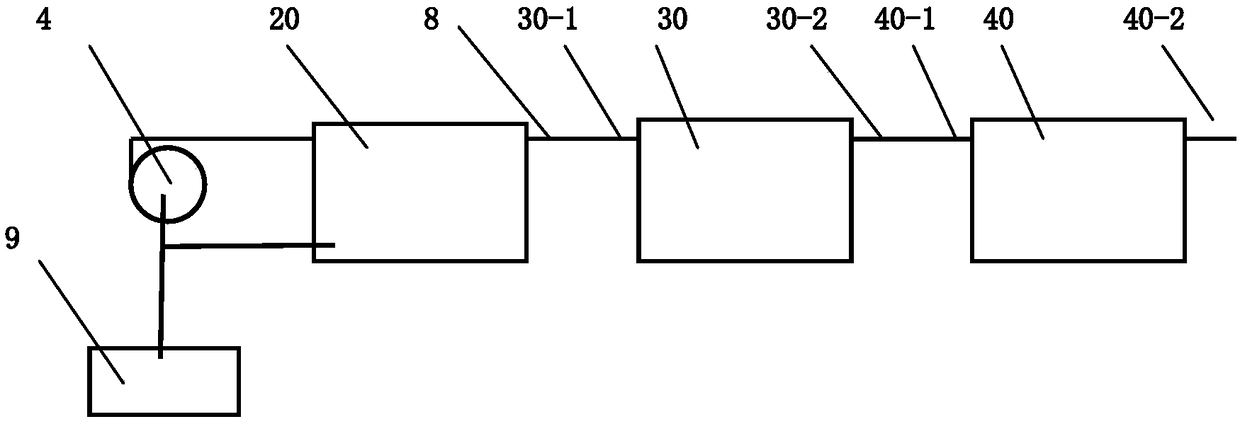

[0024] An evaporating device using activated carbon fiber boards as evaporating plates, which is composed of an evaporating tank (20), a cold well (30), an air extractor (40), a cleaning water tank (9), and a water pump (4), and is characterized in that the evaporating tank The air outlet (8) of (20) is connected with the air inlet (30-1) of the cold well, and the air outlet (30-2) of the cold well is connected with the air inlet (40-1) of the air extractor, and the air is extracted The air outlet (40-2) of the machine is connected to the atmosphere;

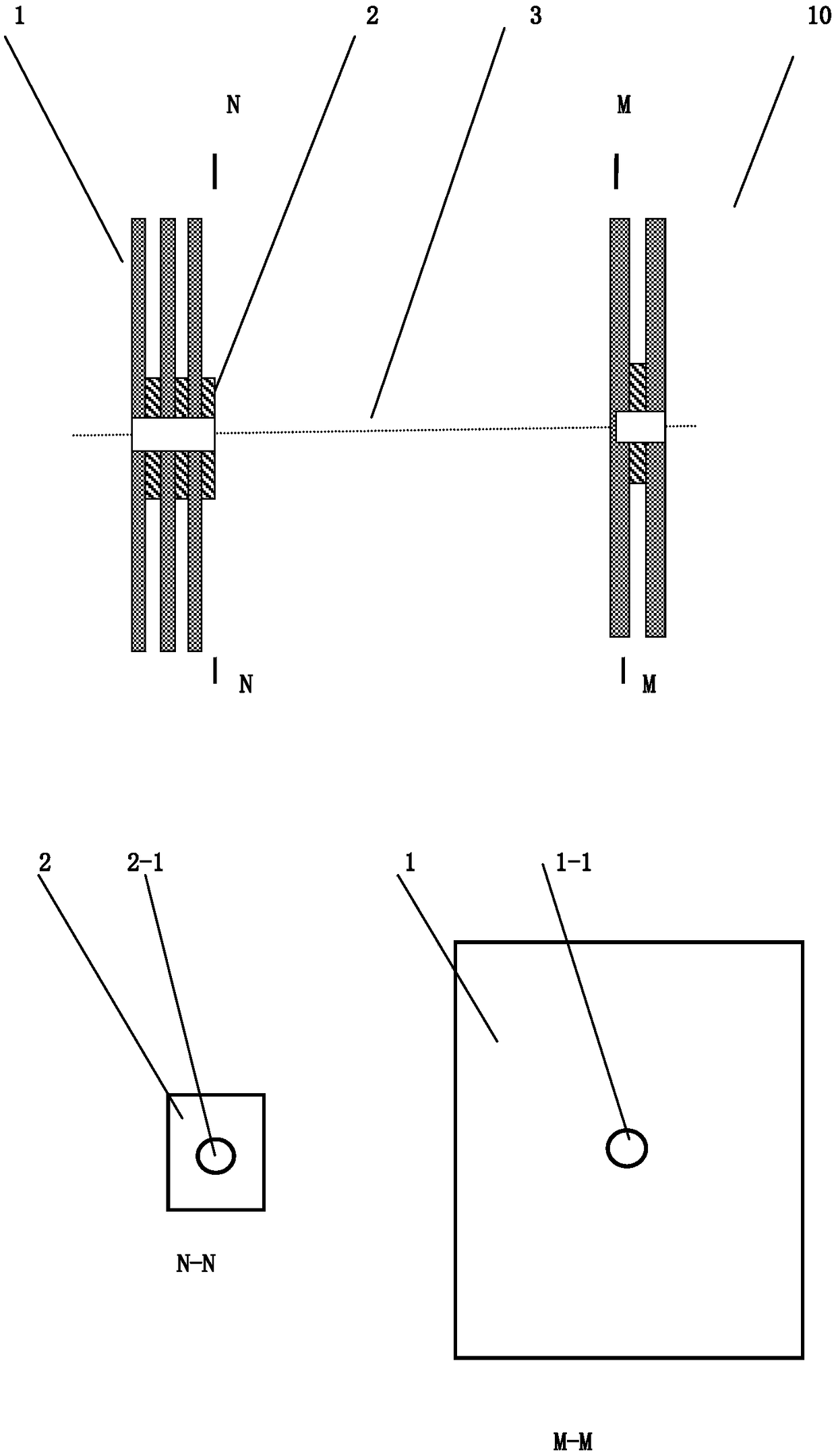

[0025] The evaporating tank (20) consists of a perforated grid plate (12), a heating pipe (14), a screw pusher (13), an evaporating assembly (10) using an activated carbon fiber board as an evaporating plate, a spray head (6) and a tank Body (7) constitutes;

[0026] The cylindrical tank body (...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap