Support device used for roll forging machine tool

A technology for supporting devices and machine tools, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc. Extend the service life and realize the effect of station conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples.

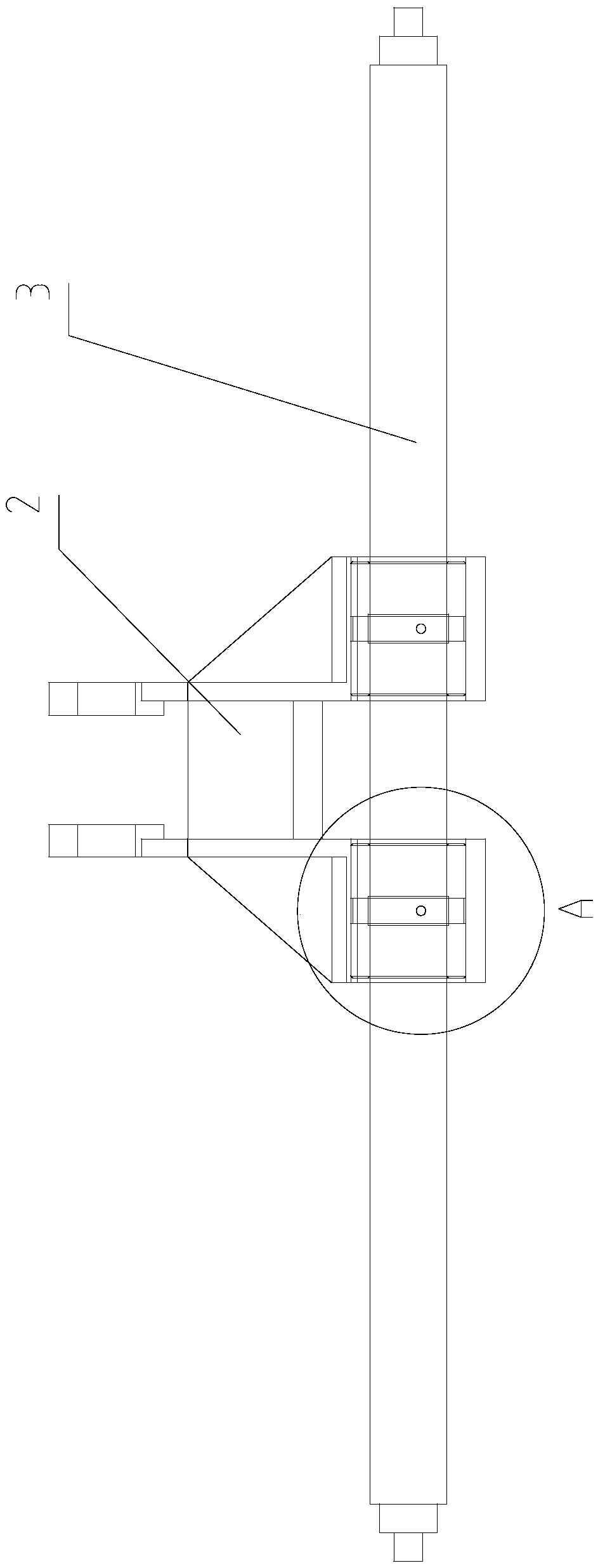

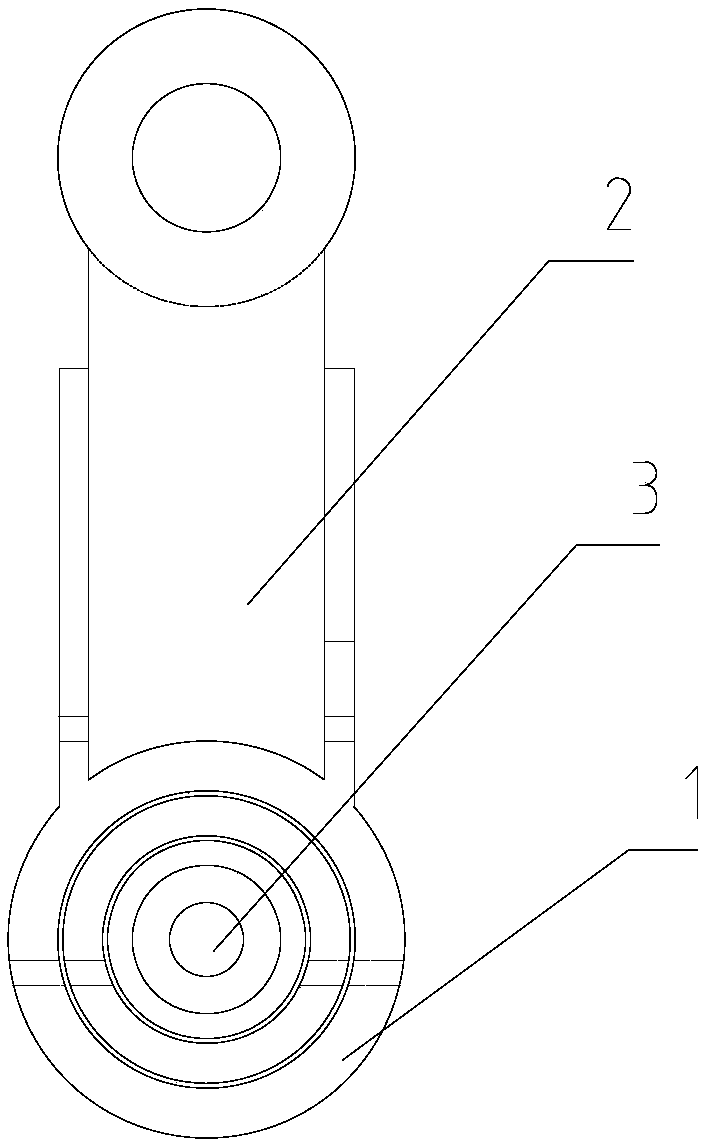

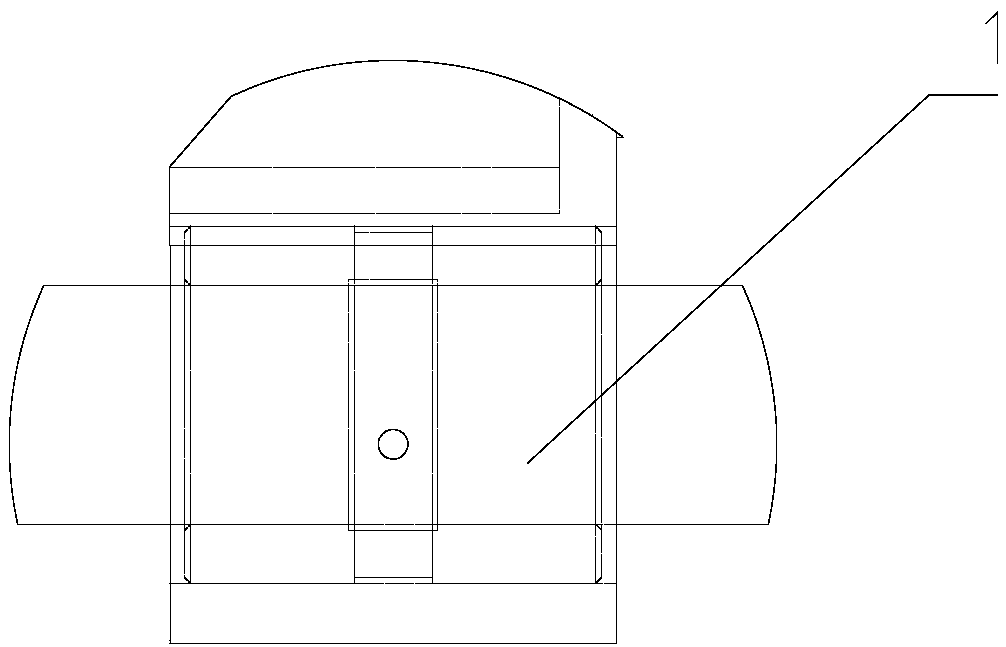

[0020] A supporting device for a roll forging machine tool, which is provided with a bushing 1, an inner hole is arranged on the bushing 1, and a support shaft 3 is arranged in the inner hole, the gap fit is between the support shaft 3 and the bushing 1, and the outer wall of the bushing 1 A bracket 2 is arranged on it, and the interference fit between the bracket 2 and the bushing 1 is provided. The upper end of the bushing 1 wall is provided with an oil injection hole 5, and the diameter of the oil injection hole 5 is 2 mm, which can be used in conjunction with most oil injection nozzles. There is an oil groove 4 on the inner hole of the bushing 1, and the lubricating oil is injected into the bushing 1 from the oil injection hole 5 and enters the oil groove 4. During the process of automatic feeding and station conversion, it plays a good lubricating effect and effectively reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com