Full-automatic assembly device for luggage connecting piece

A technology for assembling devices and connectors, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

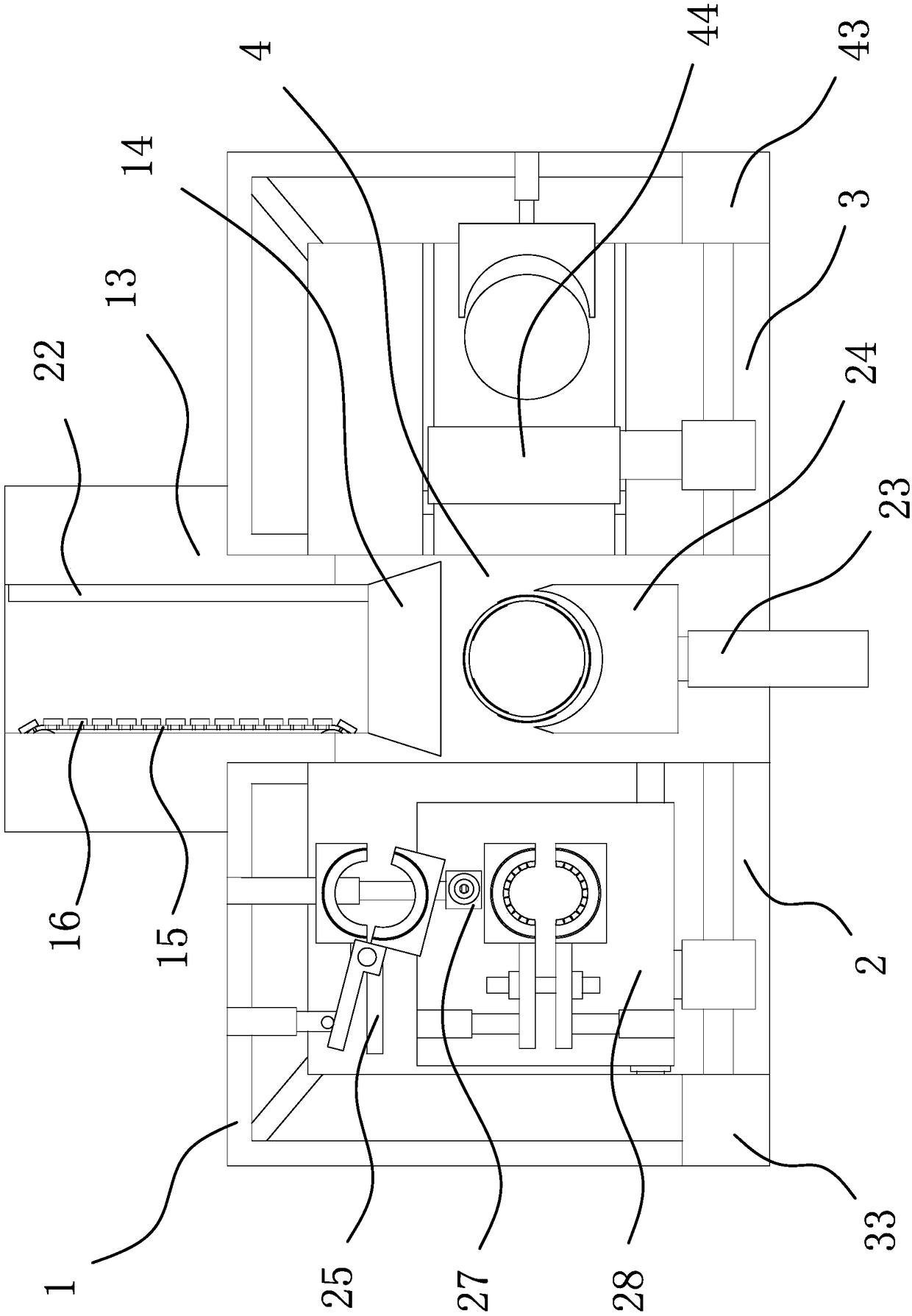

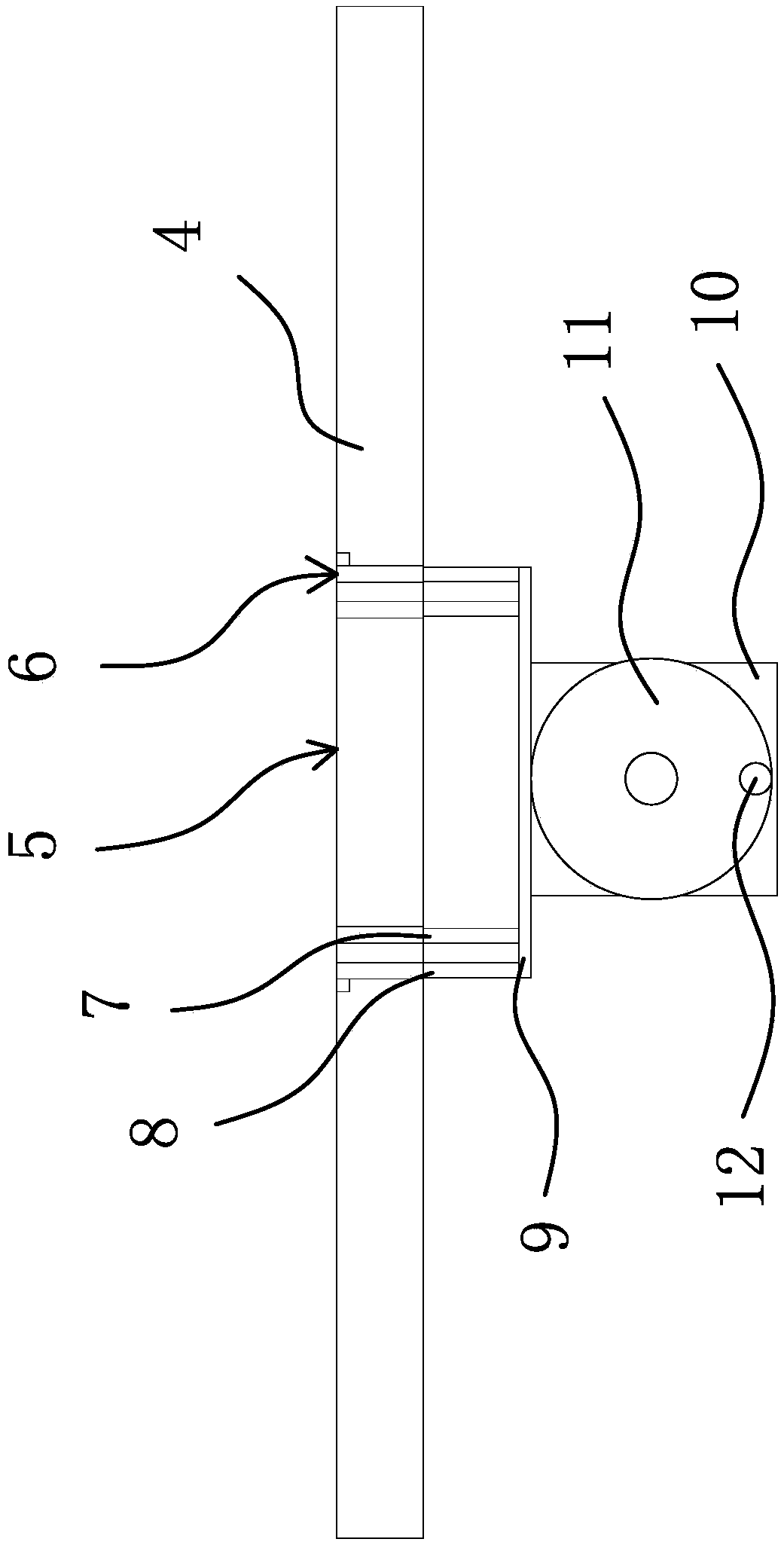

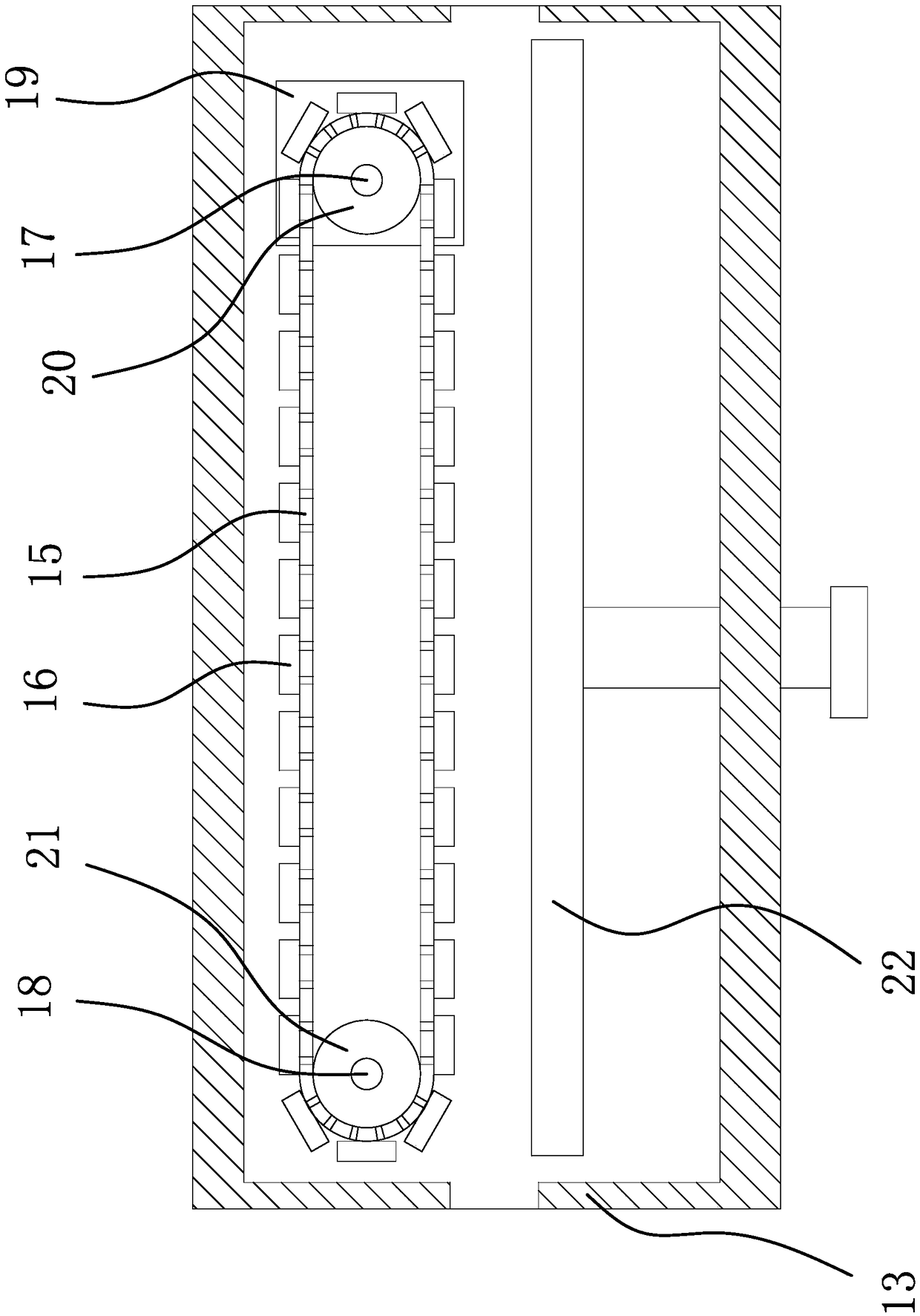

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0040] The utility model relates to a luggage connector, which is composed of a plastic part and a sealing ring, and is widely used in the manufacture of luggage. Specifically, the plastic part includes a cylindrical body, and two annular slots are opened on the upper circumference of the body. The middle part of the body is hollow, and the middle part of the body is integrally formed with a partition, and the middle part of the partition has a straight hole. , the two ends of the body are in the shape of a truncated cone with gradually decreasing diameter, and several through grooves are opened on the outer wall of the body along its axial direction; the sealing ring is made of rubber material, and is in the same shape as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com