Polishing table device of explosion-proof motor

An explosion-proof motor and grinding table technology, applied in electromechanical devices, grinding/polishing safety devices, manufacturing of motor generators, etc. The effect of reducing costs, overcoming jitter, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

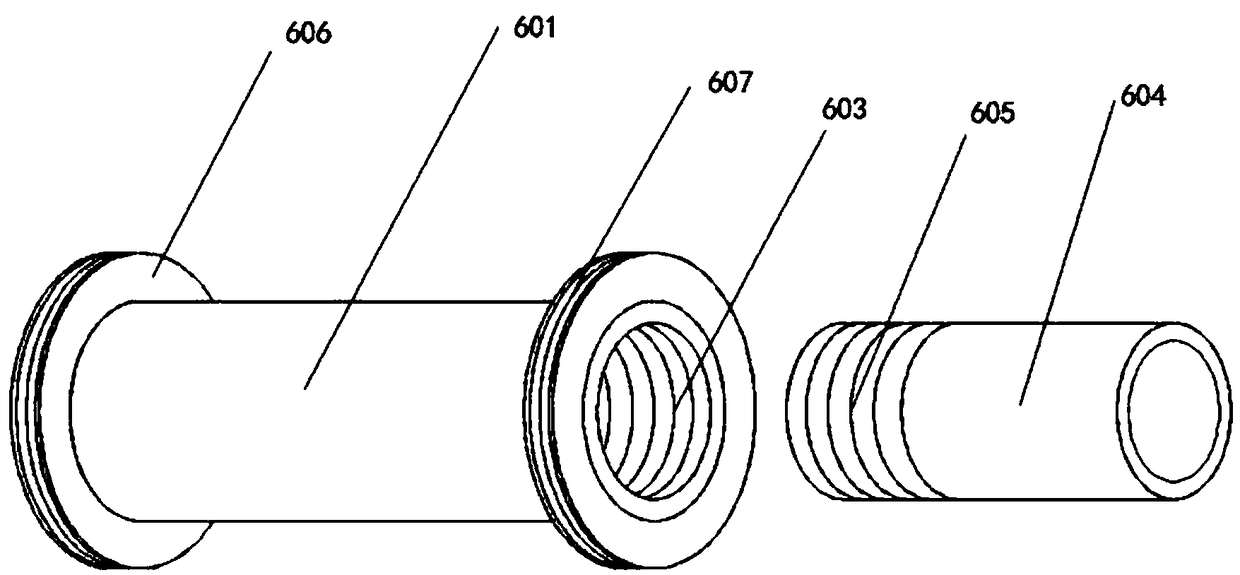

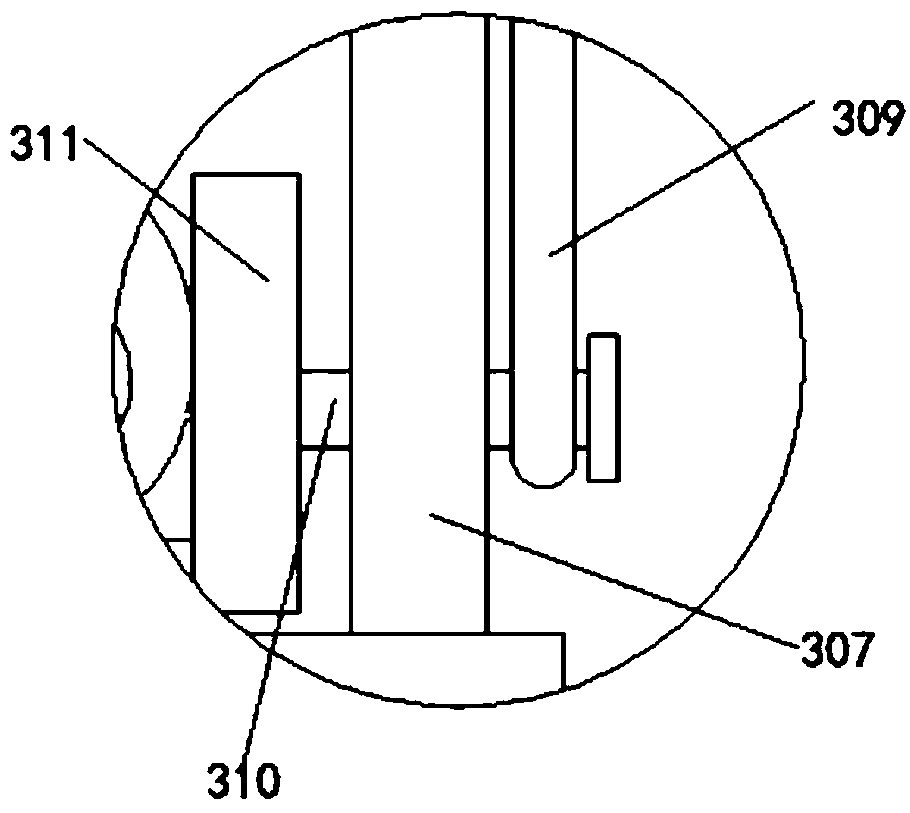

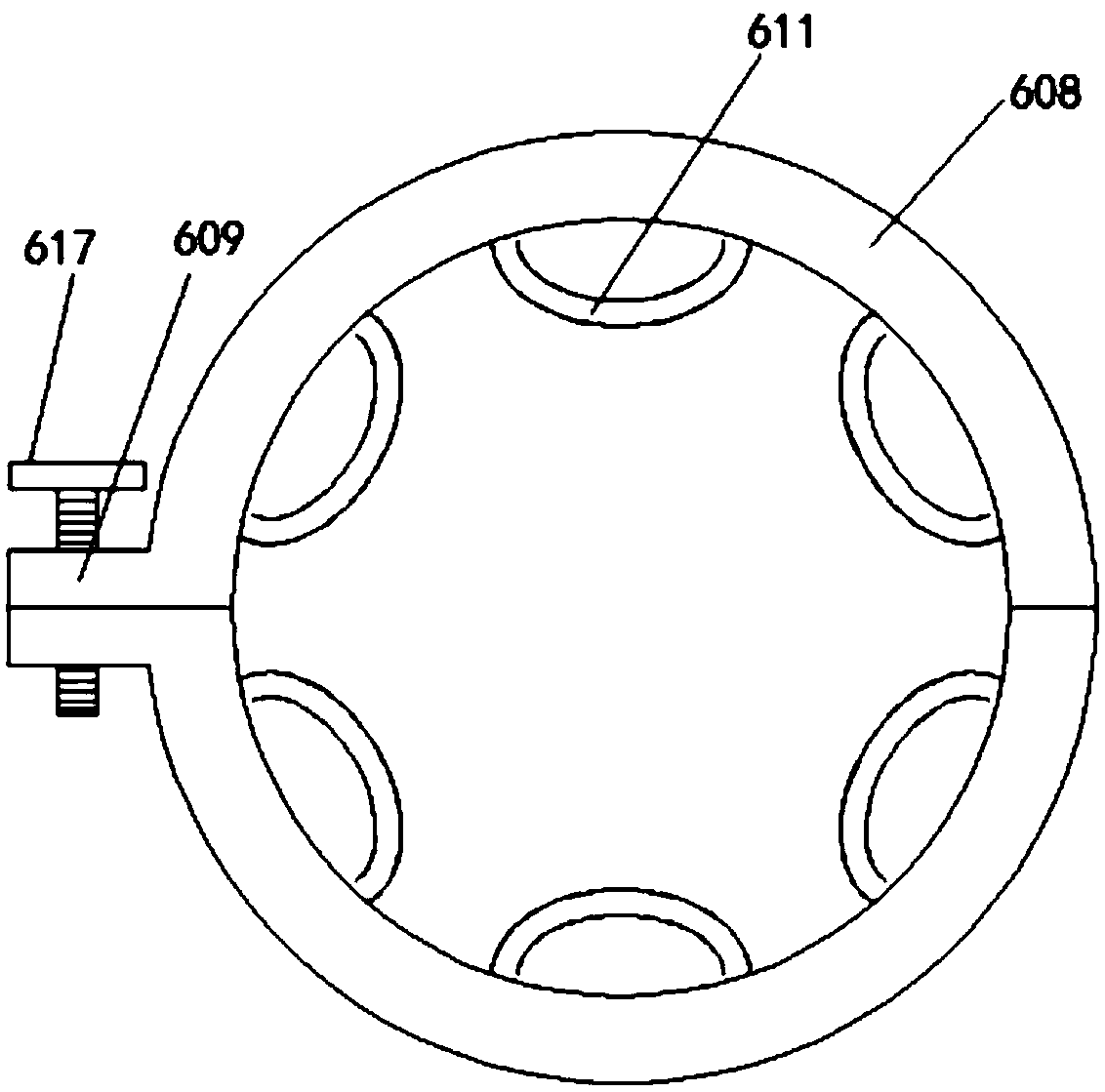

[0042] like Figure 1-Figure 5 As shown, the explosion-proof motor grinding table device includes the explosion-proof motor grinding table device described in the application number "201721343736.4", the application date is "2017.10.19" and the patent name is "an explosion-proof motor shell grinding table";

[0043] The explosion-proof motor grinding table device includes a concave operating table, a rectangular operating table and a bottom plate. A motor is embedded in the middle of the groove wall on one side of the concave operating table, and the output end of the motor is connected to one end of the rotating shaft through a coupling. Transmission connection; both ends of the groove wall on one side of the concave operation table are provided with electric push rods, one end of the two electric push rods is respectively connected to the two ends of the push plate side by transmission, and the middle part of the shaft runs through The center of the push plate, the other end...

Embodiment 2

[0050] like Figure 1-Figure 8 As shown, the explosion-proof motor grinding table device includes the explosion-proof motor grinding table device described in the application number "201721343736.4", the application date is "2017.10.19" and the patent name is "an explosion-proof motor shell grinding table";

[0051] The explosion-proof motor grinding table device includes a concave operating table, a rectangular operating table and a bottom plate. A motor is embedded in the middle of the groove wall on one side of the concave operating table, and the output end of the motor is connected to one end of the rotating shaft through a coupling. Transmission connection; both ends of the groove wall on one side of the concave operation table are provided with electric push rods, one end of the two electric push rods is respectively connected to the two ends of the push plate side by transmission, and the middle part of the shaft runs through The center of the push plate, the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com