Hollow drill bit for water seal punching and use method thereof

A hollow drill and water seal technology, applied in metal processing and other directions, can solve the problem of water seal rubber being difficult to remove, and achieve the effects of reducing friction, improving efficiency, and simplifying the use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

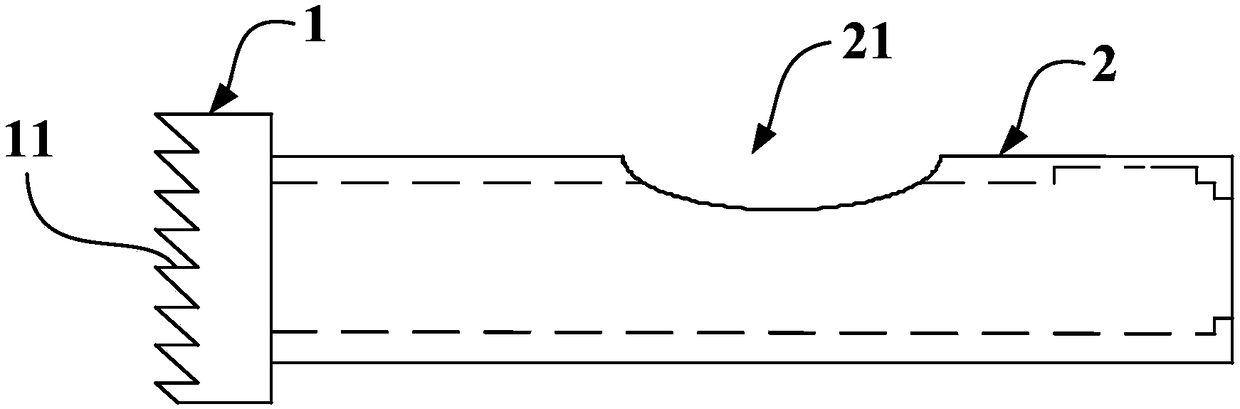

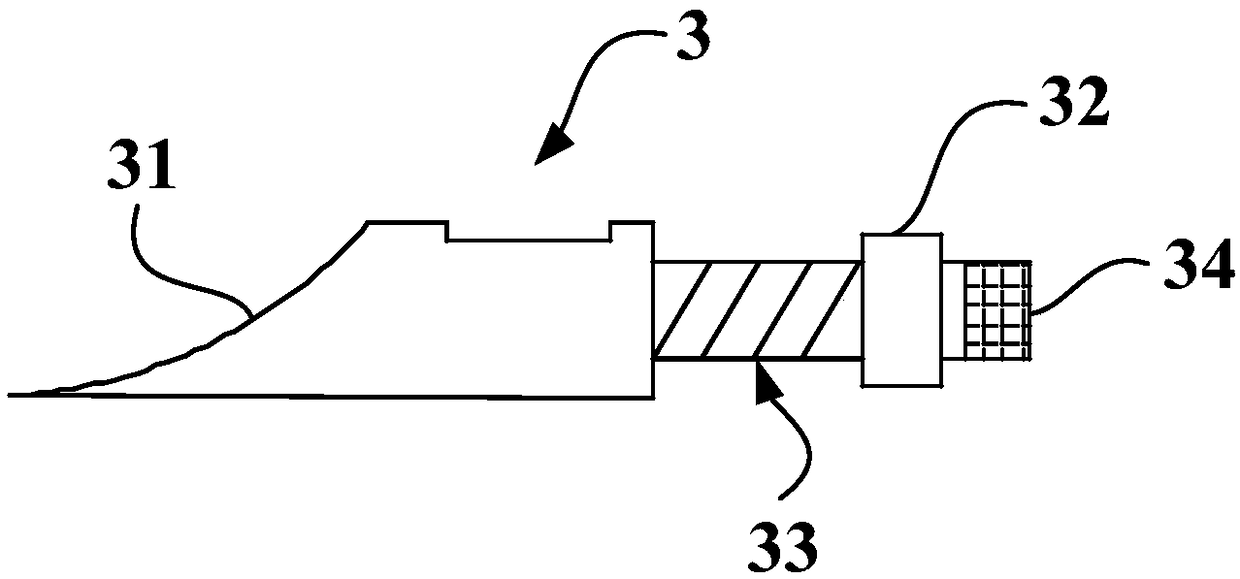

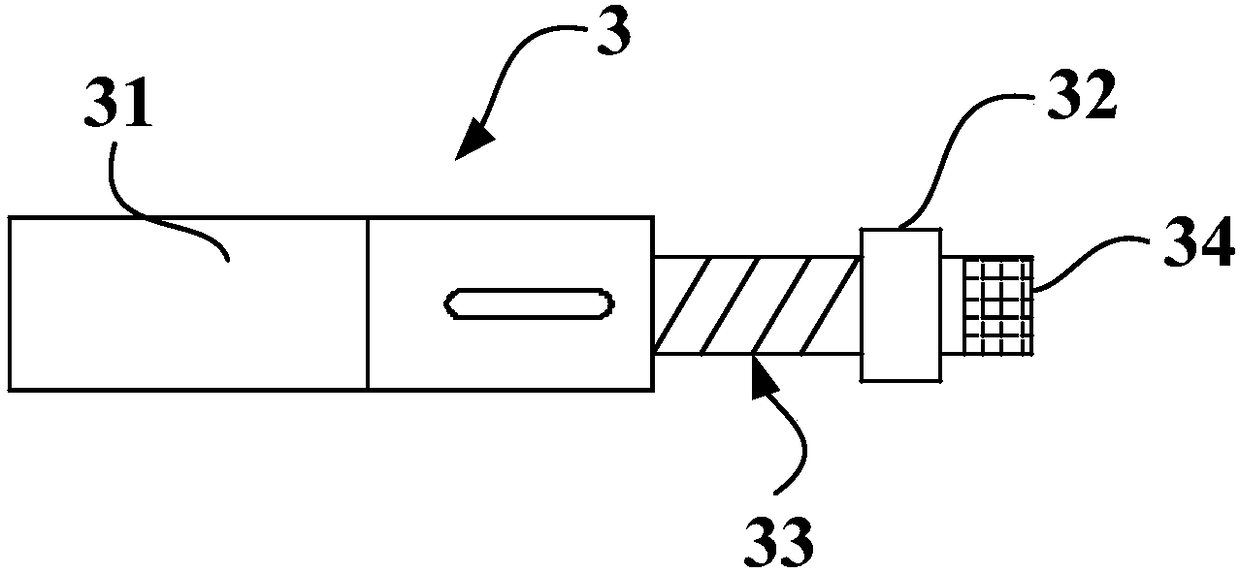

[0023] Embodiment 1 of the present invention provides a hollow drill bit for water-sealed drilling. Hollow drill bits for water-seal drilling, including drilling parts, sleeves and discharge guides; the drilling parts are hollow and arranged at one end of the sleeve and communicated with the sleeve, drilling There are multiple conical teeth on the end surface away from the sleeve, and the tooth width of the conical teeth gradually increases along the direction from the top of the conical tooth to the root of the tooth; the tube wall of the sleeve is provided with a discharge port ; One end of the discharge guide is plugged into the sleeve and the discharge guide has a guide surface to guide the drilled material out of the drill to the discharge port, and the discharge guide and the sleeve are connected by a key to realize synchronous rotation; The other end of the material guide protrudes from the sleeve, and the other end of the discharge guide is provided with a positioning ...

Embodiment 2

[0035] Embodiment 2 of the present invention provides a kind of using method of the hollow drill bit that water seal perforation is used, and this method uses the hollow drill bit that water seal perforation is used as in embodiment one; Using method comprises the steps:

[0036] S01, set one end of the discharge guide in the sleeve and connect with a key to ensure that the two rotate synchronously;

[0037]In this step, connect the discharge guide and the sleeve through a key connection, and adjust the discharge guide surface to a position corresponding to the discharge port;

[0038] S02, the elastic reset member is sleeved on the discharge guide member extending out of the sleeve, and the positioning member is arranged on the discharge guide member;

[0039] In this step, an elastic return member such as a spring is sleeved on the other end of the discharge guide, and the elastic return member is pressed by the positioning member to prevent the elastic return member from de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com