A high-precision cold-pressing device for special-shaped wood strips

A high-precision, special-shaped technology, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve problems such as small application range, poor pressing stability, and cracking of wooden strips, so as to improve the application range and improve Work stability, the effect of improving the pressing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

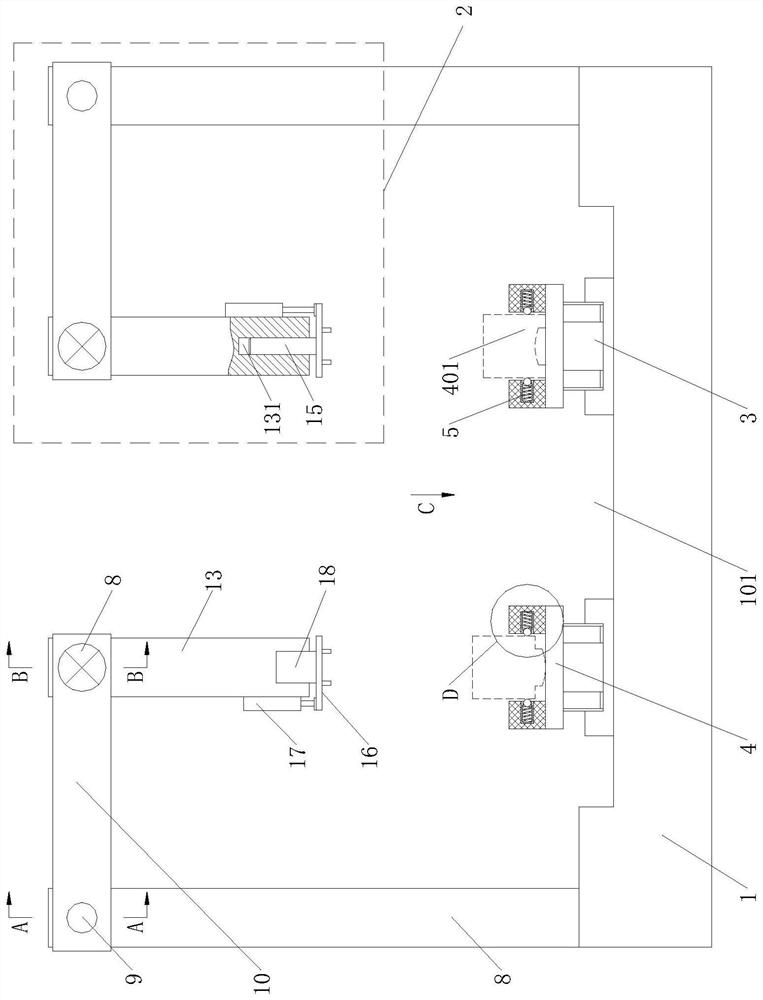

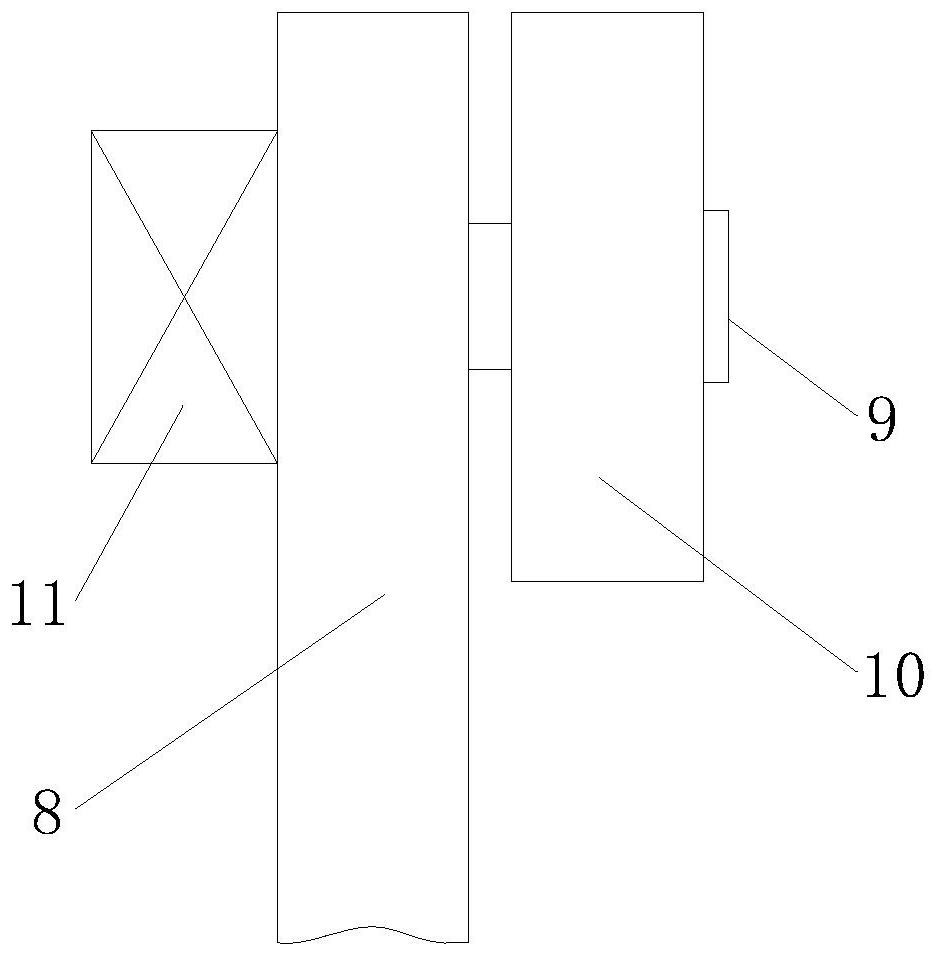

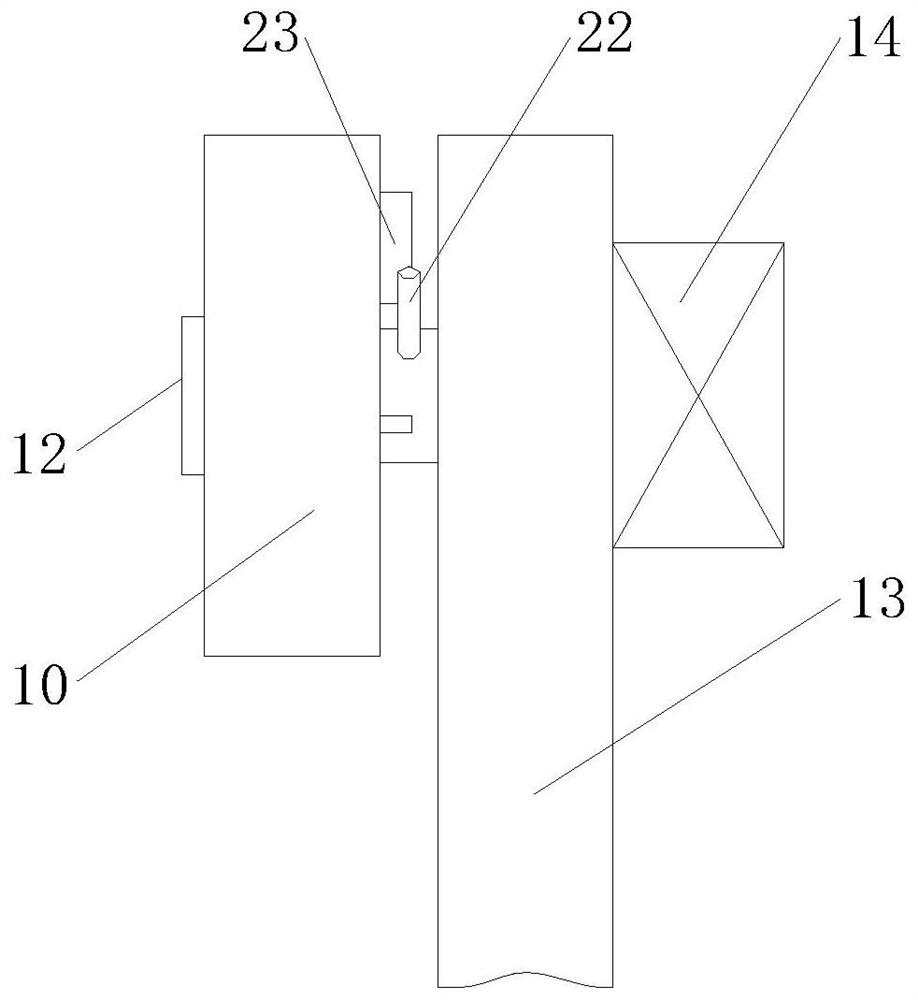

[0016] Examples. A high-precision cold-pressing device for special-shaped wooden strips, composed as figure 1 As shown, the workbench 1 is included. The center of the workbench 1 is provided with a conveying channel 101, and two guide rails 3 are arranged side by side in the conveying channel 101. Each guide rail 3 is provided with a movable positioning seat 4, and the center of the positioning seat 4 is provided There is a positioning groove 401. A plurality of locking components 5 are provided on both sides of the positioning groove 401 through a rectangular groove 402. The positioning seats 4 on the two guide rails 3 are connected to each other by a push plate 6, and one end of the push plate 6 is connected with a pushing cylinder 7; The conveying channel 101 is provided with a symmetrical grasping device 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com