New vacuum brick equipment

A new type of vacuum technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of wall leakage, low mortar fullness, waste of cement mortar, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

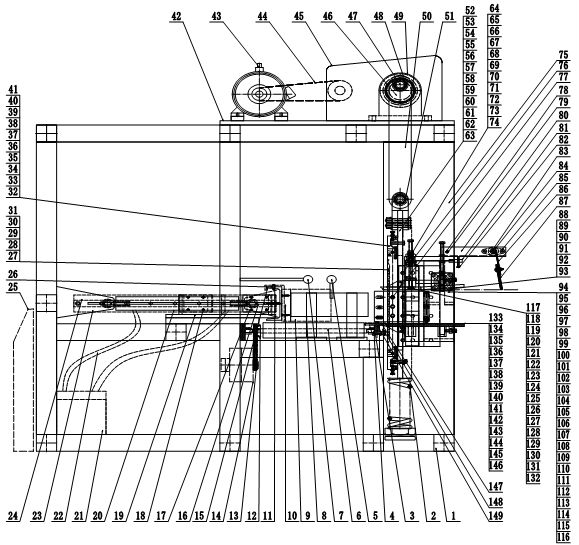

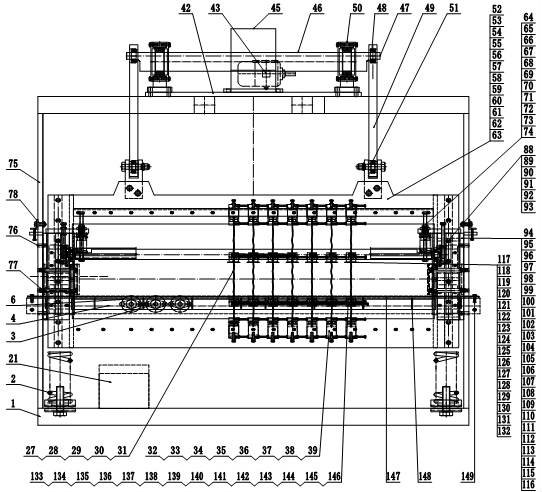

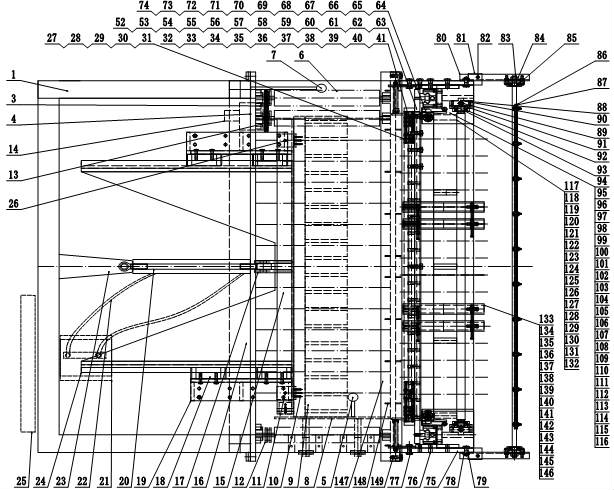

[0050] The present invention is further explained in conjunction with the accompanying drawings: the new vacuum brick equipment used in the new building materials industry consists of a frame 1, a push plate 15, an S streamlined blade 27, a knife hanging fixture 32, a power base steel plate 42, and a knife frame 52, internal and external thread cylinder 64, side wall plate 75, screw bearing seat 88, knife frame slide block base 94, upper pressing plate rotating shaft frame 117, lower supporting plate 133 twelve parts are formed.

[0051] Frame 1 is welded by a plurality of square steel, which consists of spring 2, roller seat bearing 3, roller bar 4, adobe rear sensor 5, roller 6, adobe front sensor 7, adobe baffle 8. Composition of wooden bricks 9, billet cleaning push plate 10, positioning pin steel plate 11, sprocket wheel 12, chain 13, roller motor 14; spring 2 is fixed on the square steel on the bottom surface of frame 1 to absorb and release the knife frame 52 to move up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com