A frame structure with variable facula for sla 3D printer

A printer and variable technology, applied in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve problems such as poor printing accuracy, changes in light spot positioning, low positioning accuracy and concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

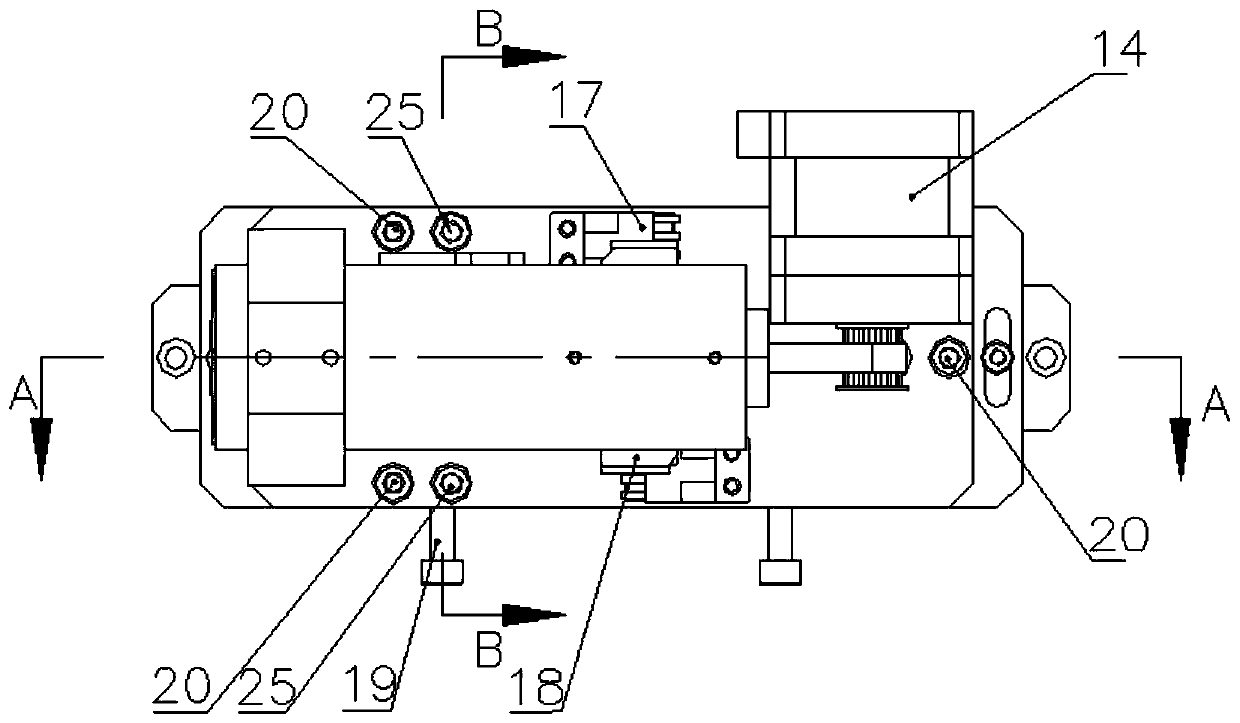

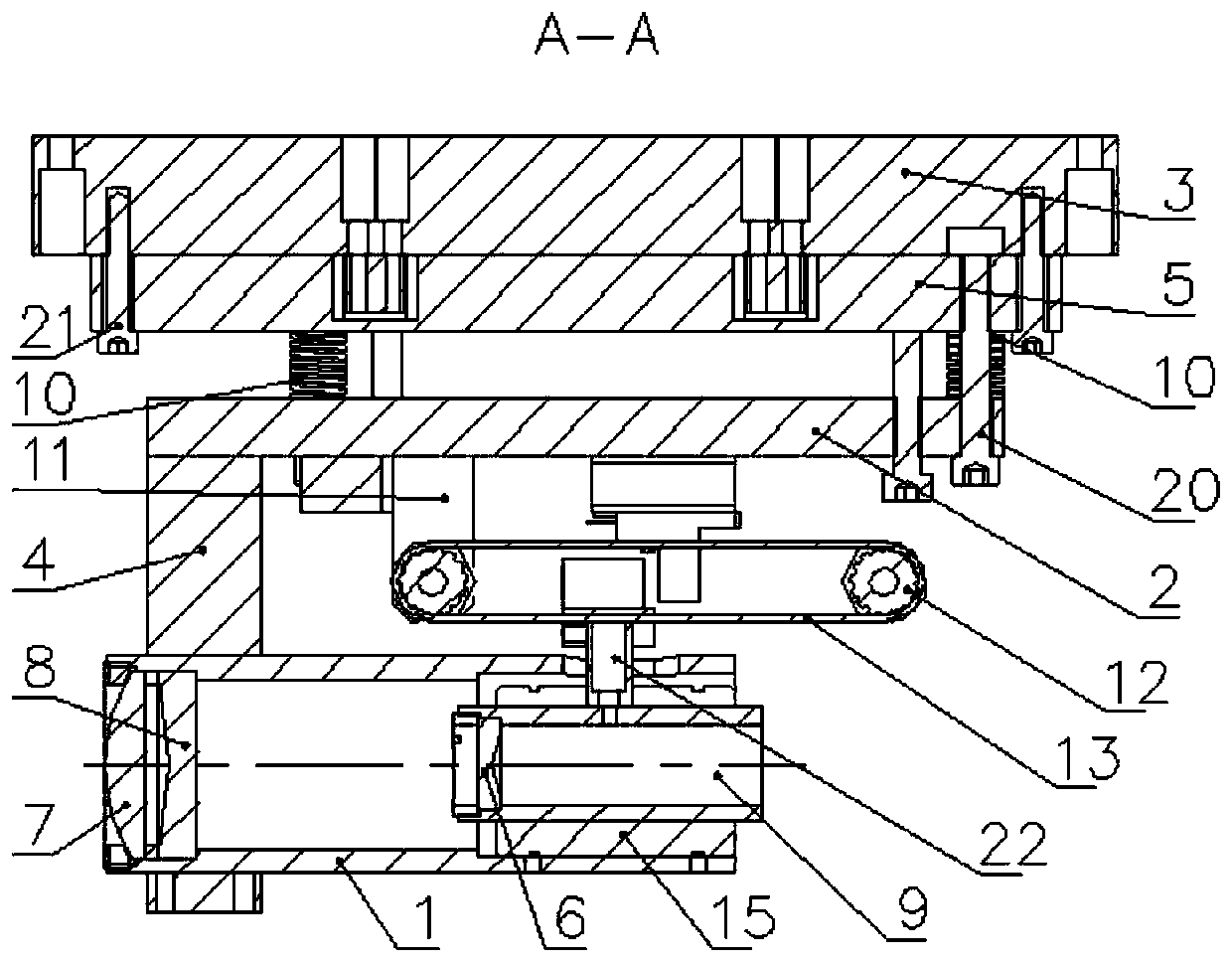

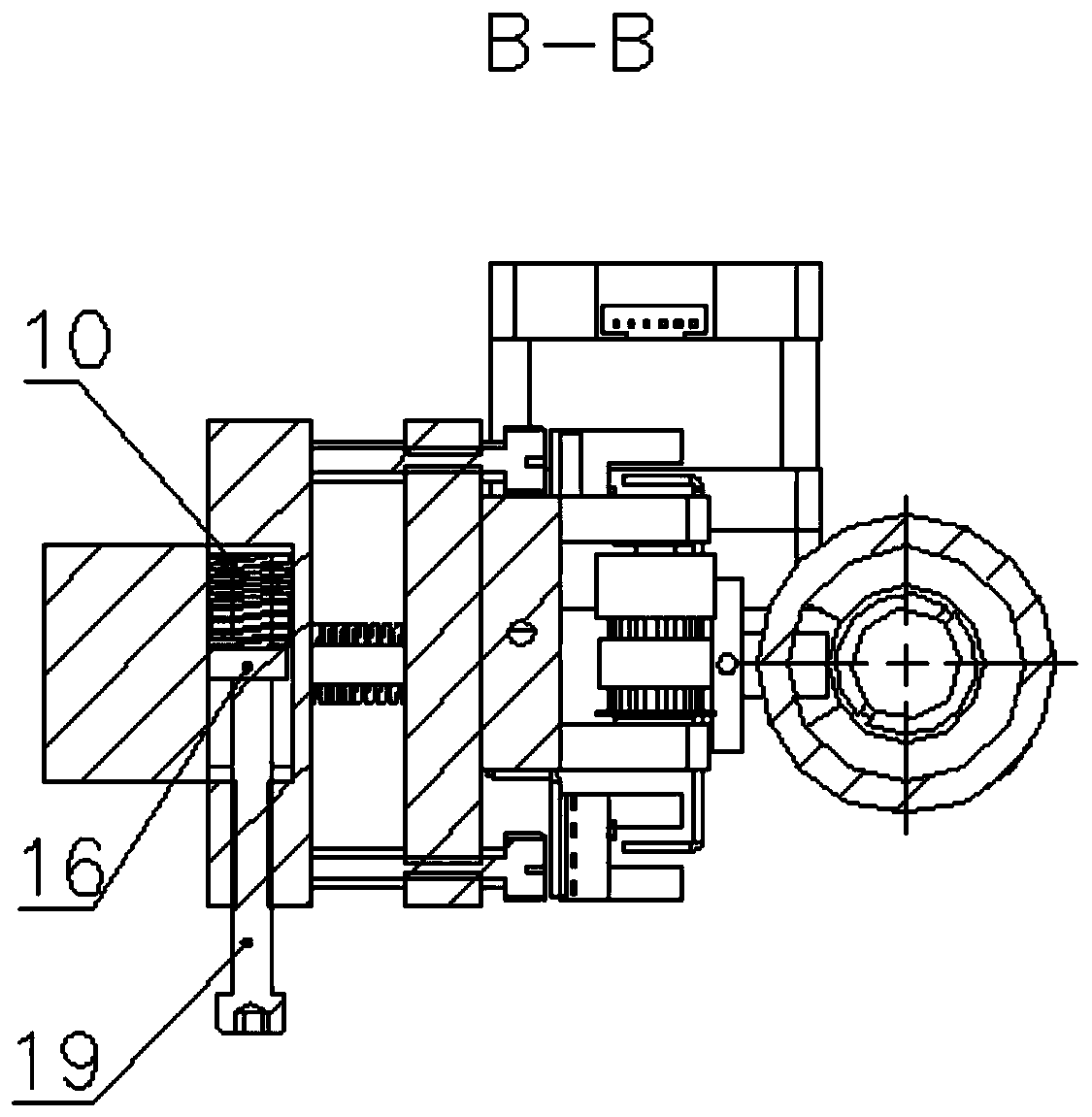

[0019] Such as Figure 1-3 As shown, the present invention provides an SLA 3D printer variable spot frame structure, including a lens barrel 1, a dimming base plate 2, a support 3 and a left and right adjustment plate 5, and the lower end of the support 3 is installed with left and right sides through screws M4X25 21 Adjustment plate 5, and the two ends of left and right adjustment plate 5 are all provided with the elongated screw hole that is used to install screw M4X25 21, and the two ends of left and right adjustment plate 5 sides are all equipped with screw M5X40 19, and screw M5X40 19 and left and right adjustment plate 5 There are springs 10 clamped between them, and the lower end of the left and right adjustment plates 5 is equipped with a dimming bottom plate 2 through screws M5X35 20, and springs 10 are set on the screws M5X35 20, and the springs 10 are clamped on the bottom surface of the left and right adjustment plates 5 and the dimming Between the top surfaces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com