Dipping glue type shoe sole processing method and shoe sole processing equipment

A processing method and processing equipment technology, applied to footwear, other household appliances, household appliances, etc., can solve the problem of high manufacturing cost of shoe sole molds, heavy weight of finished shoes, wear resistance, anti-slip, corrosion resistance and other unstable physical properties and other issues, to achieve the effect of saving sole mold costs, reducing manufacturing costs, and enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

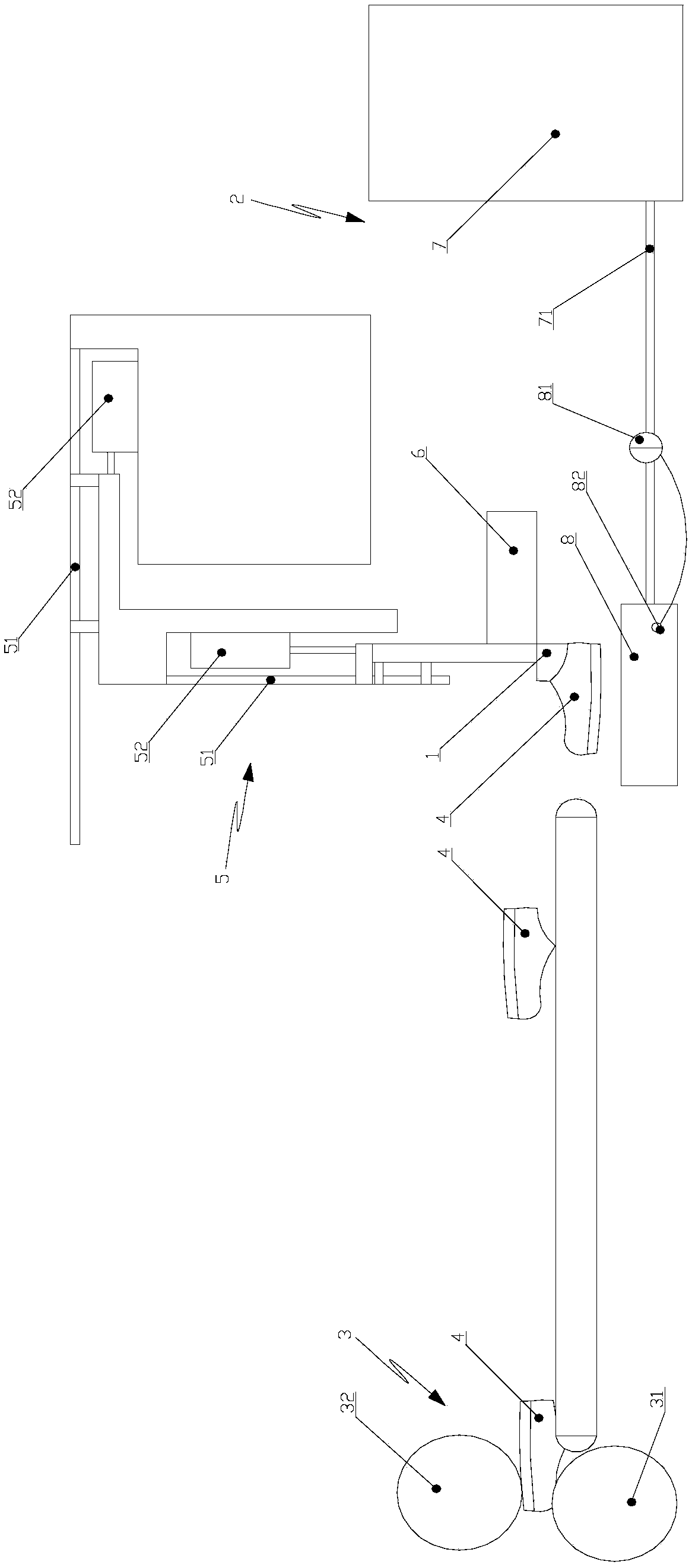

[0034] figure 1 A shoe sole processing device according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a manipulator device 1 , a dipping device 2 and an embossing device 3 .

[0035] Wherein, the manipulator device 1 is used for gripping and turning over the shoes 4 .

[0036] The manipulator device 1 is connected with a group of translational driving mechanisms 5 and a turning mechanism 6 .

[0037] The translation drive mechanism 5 includes a guide rail 51 and a drive mechanism 52 .

[0038] The driving mechanism 52 is used to drive the manipulator 1 to translate and slide along the guide rail 51 .

[0039] The turning mechanism 6 is used to drive the manipulator 1 to turn over 180° in the vertical direction.

[0040] The translation driving mechanism 52 can be a cylinder or a motor screw,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com