Sealing, cutting and winding machine used for cold packaging of cigarettes in cartons

A winding machine and cold packaging technology, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of high cost, high power consumption, and reduction, and achieve the effect of short consumption time and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

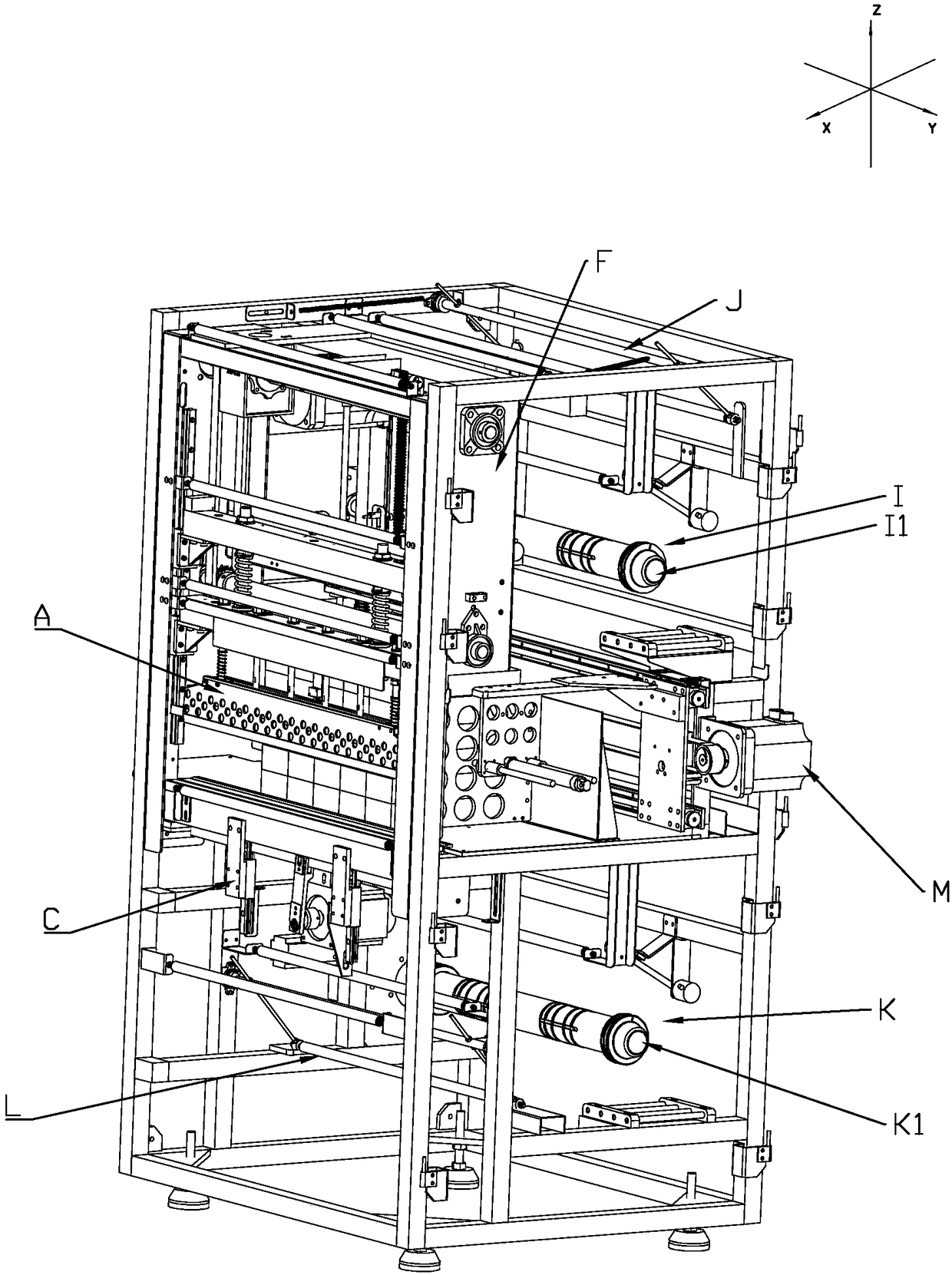

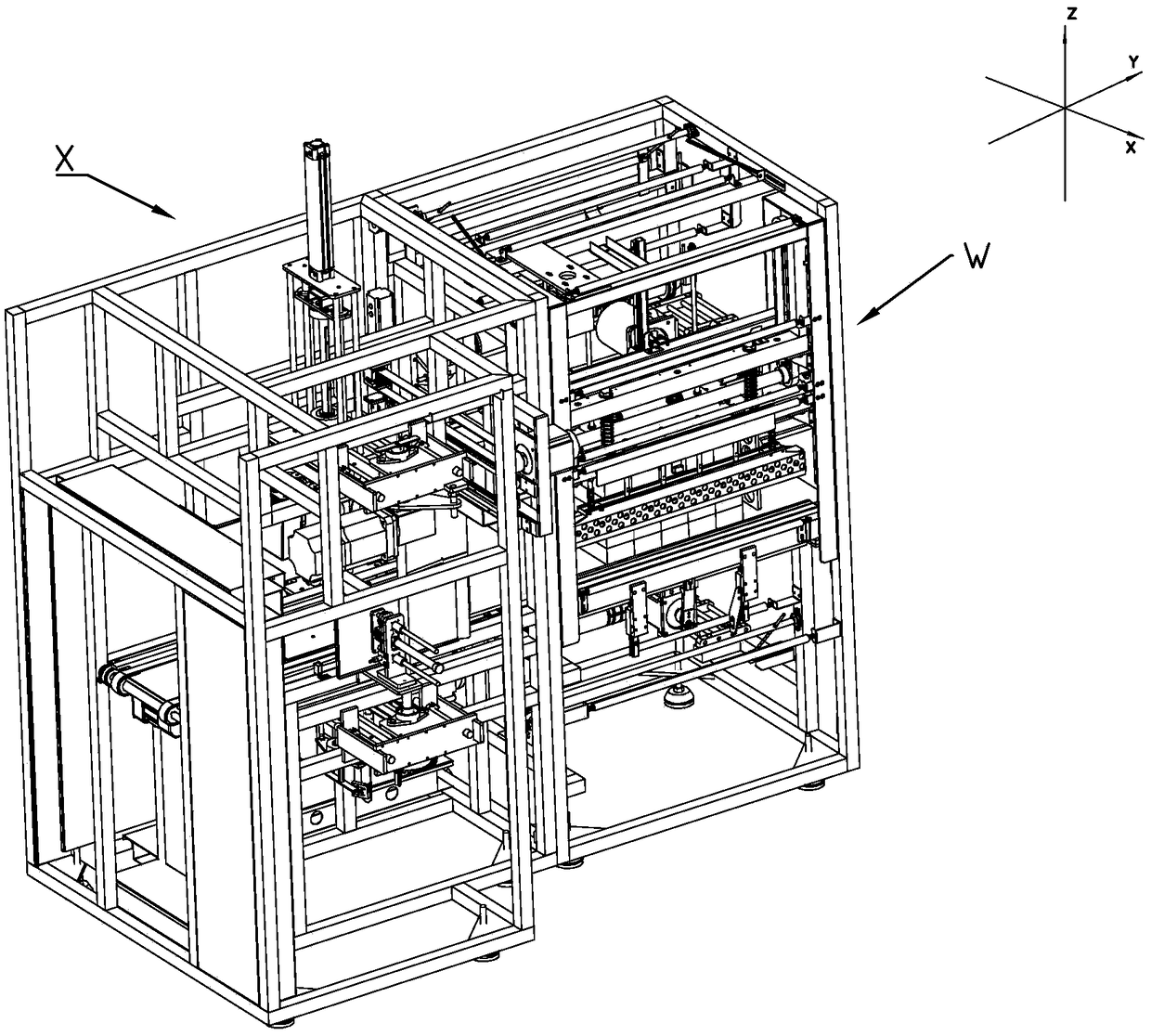

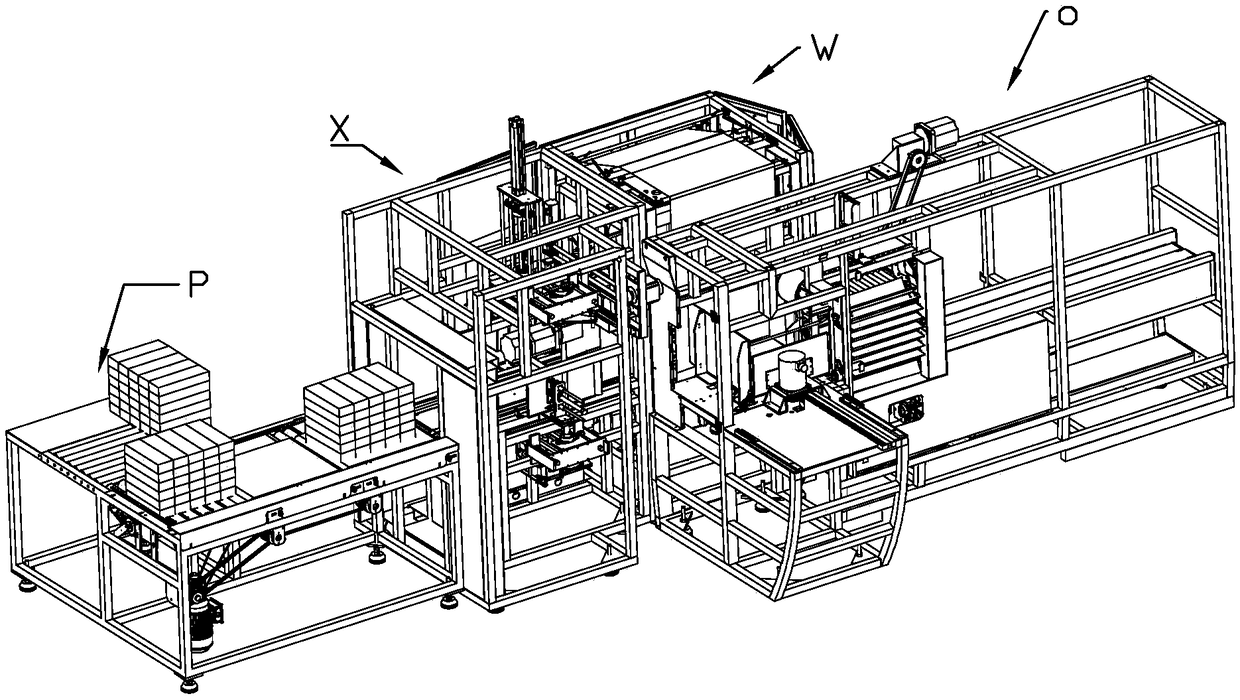

[0069] For a more complete and accurate expression, in the following, the figure 1 The X-Y-Z coordinate system of X-Y-Z expresses its positional relationship, X points to the front, X points to the right, and Z points to the top. Even in the rest of the specification drawings the viewing angles are in the same direction as figure 1 different, in the description figure 1 The coordinate system shall prevail to express the relative positional relationship of each component.

[0070] In order to observe and illustrate the specific structure of each device and component more clearly, all the devices and components in the drawings have removed the outer sheet metal components, and onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com