Double film bag type automatic packaging machine and automatic packaging process thereof

An automatic packaging machine and bag-forming technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low packaging production capacity, rising packaging cost, and inability to solve the packaging process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

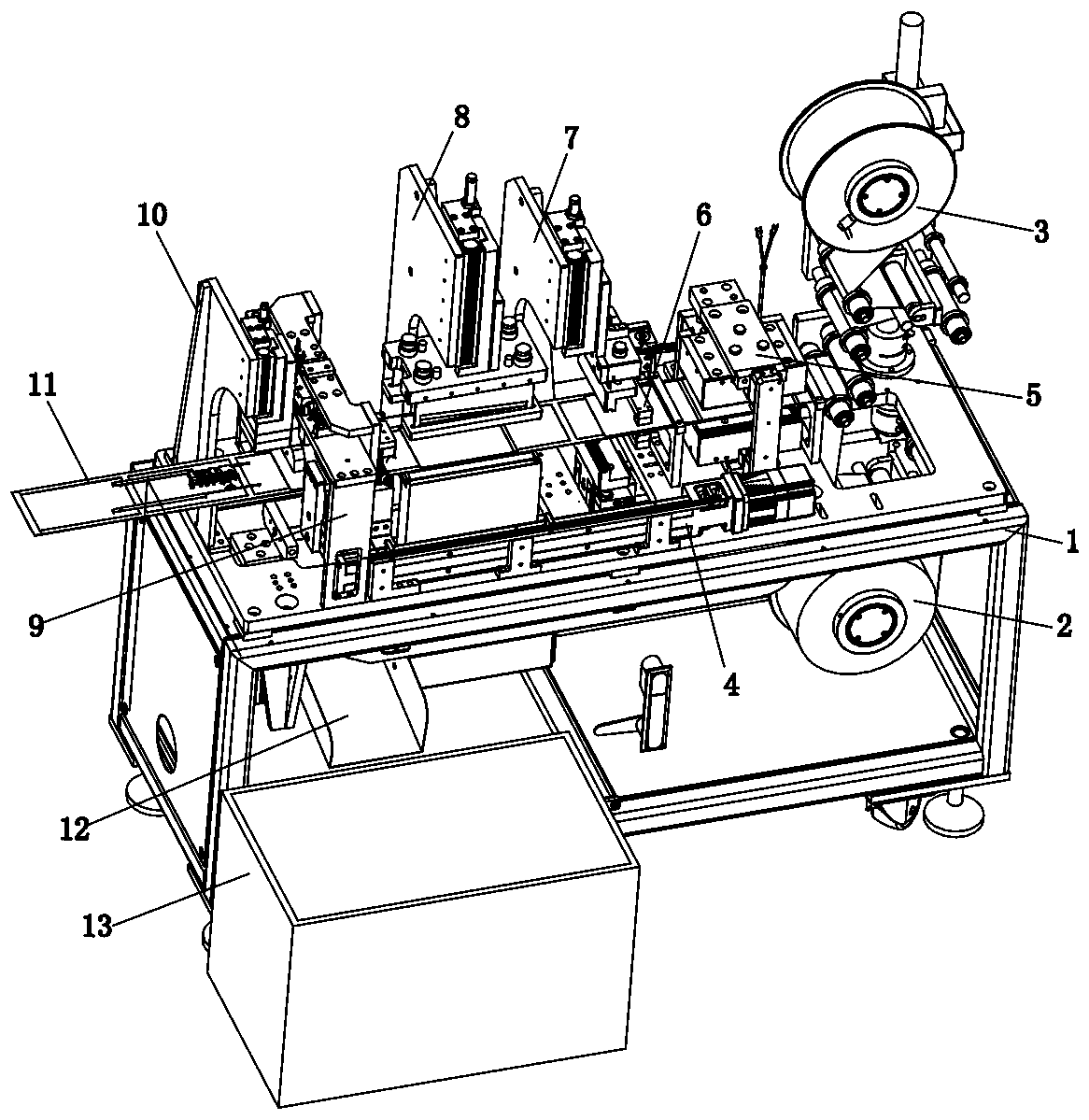

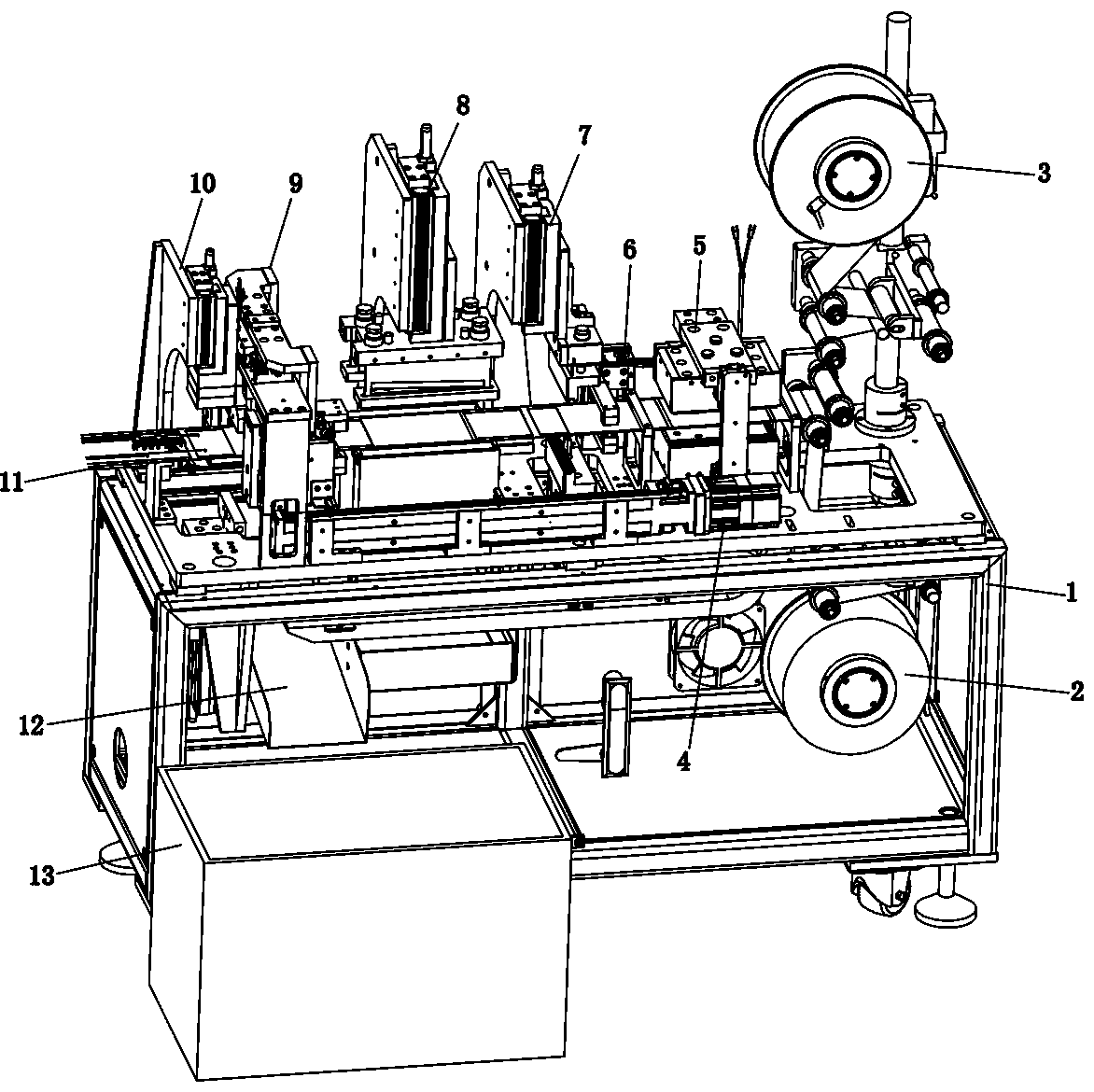

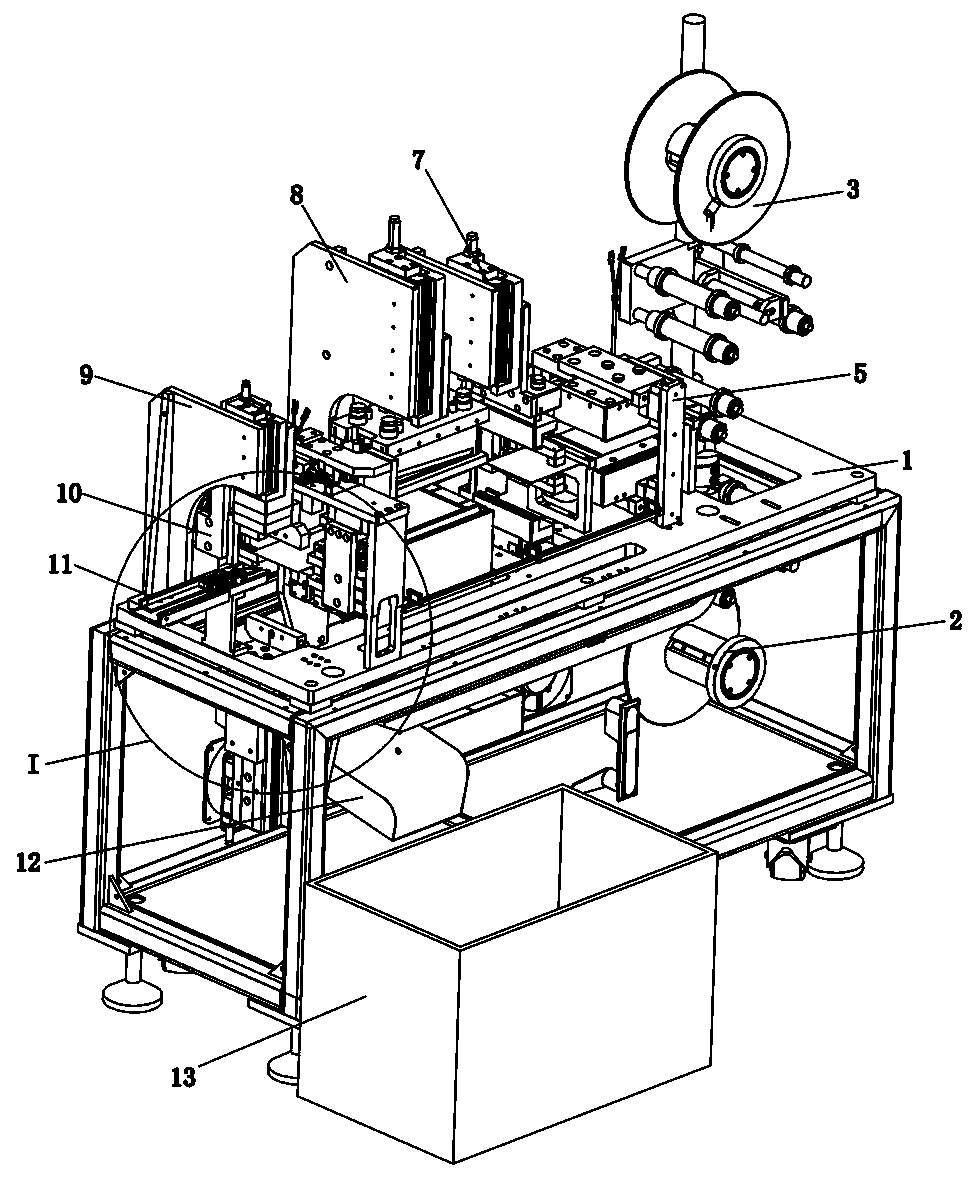

[0037] The present invention will be further described below in conjunction with accompanying drawing:

[0038] Such as Figure 1 to Figure 13 As shown, the technical scheme adopted by the present invention is as follows: a double-film bag-forming automatic packaging machine, comprising a lower film rolling mechanism 2, an upper rolling film mechanism 3, a bag body pull-out mechanism 4, a three-side heat-sealing mechanism 5, a clip Bag mechanism 6, bag cutting mechanism 7, side cutting mechanism 8, bag stretching mechanism 9, sealing mechanism 10 and material pushing mechanism 11, wherein, the above-mentioned lower rolling film mechanism 2 and upper rolling film mechanism 3 are respectively arranged on the frame 1 The lower and upper parts of the upper and lower roll film mechanism 2 and the strip film derived from the upper roll film mechanism 3 are stacked up and down; the above-mentioned bag body pull-out mechanism 4 is arranged on the frame 1 along the strip-shaped film ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com