Iron and plastic composite barrel

A technology of plastic and metal barrels, which is applied in packaging and other directions, can solve the problems of impurities mixed in, high cost of using metal packaging barrels, and low recycling rate of metal barrels, so as to ensure purity, convenient and reliable reuse, and reduce use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

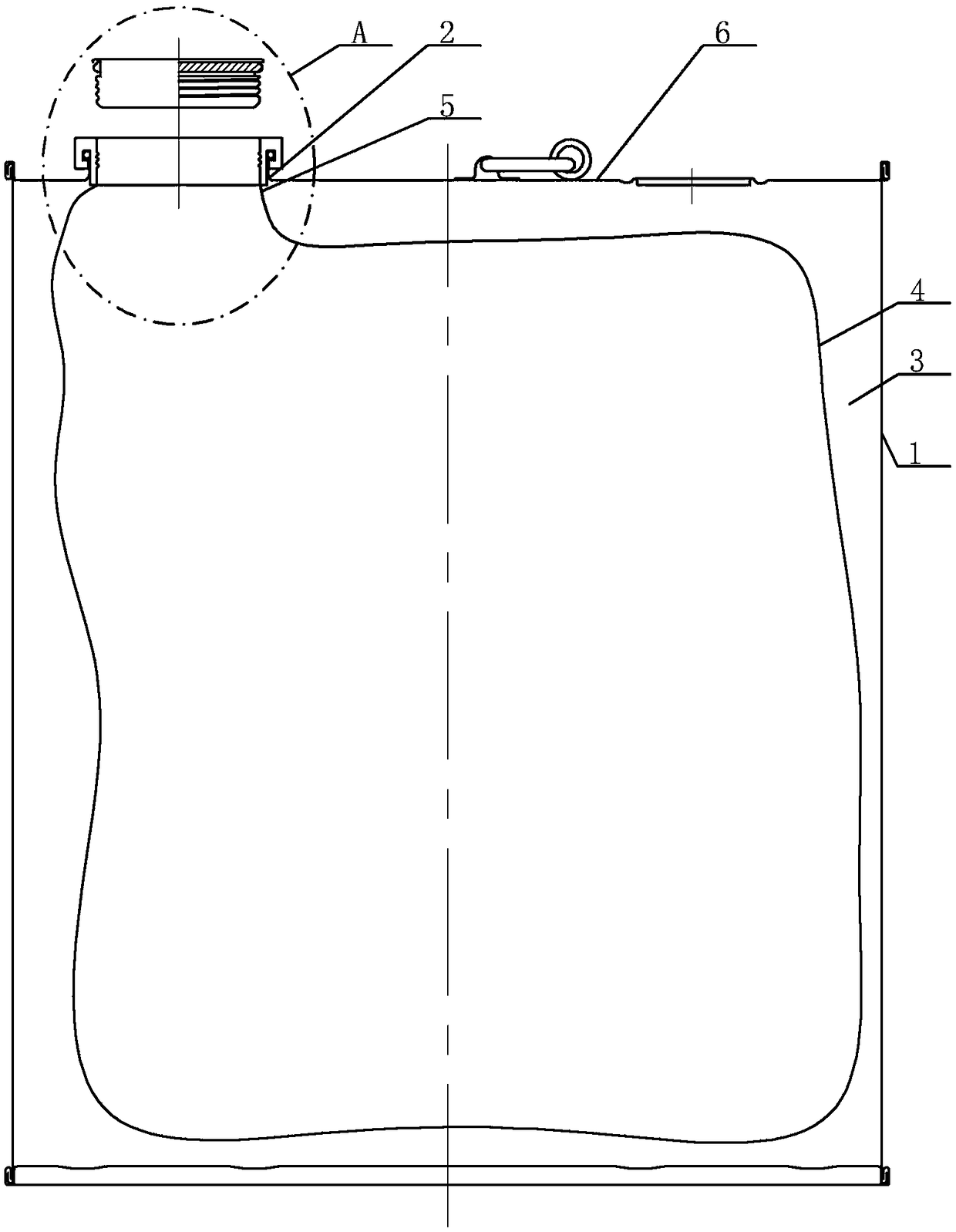

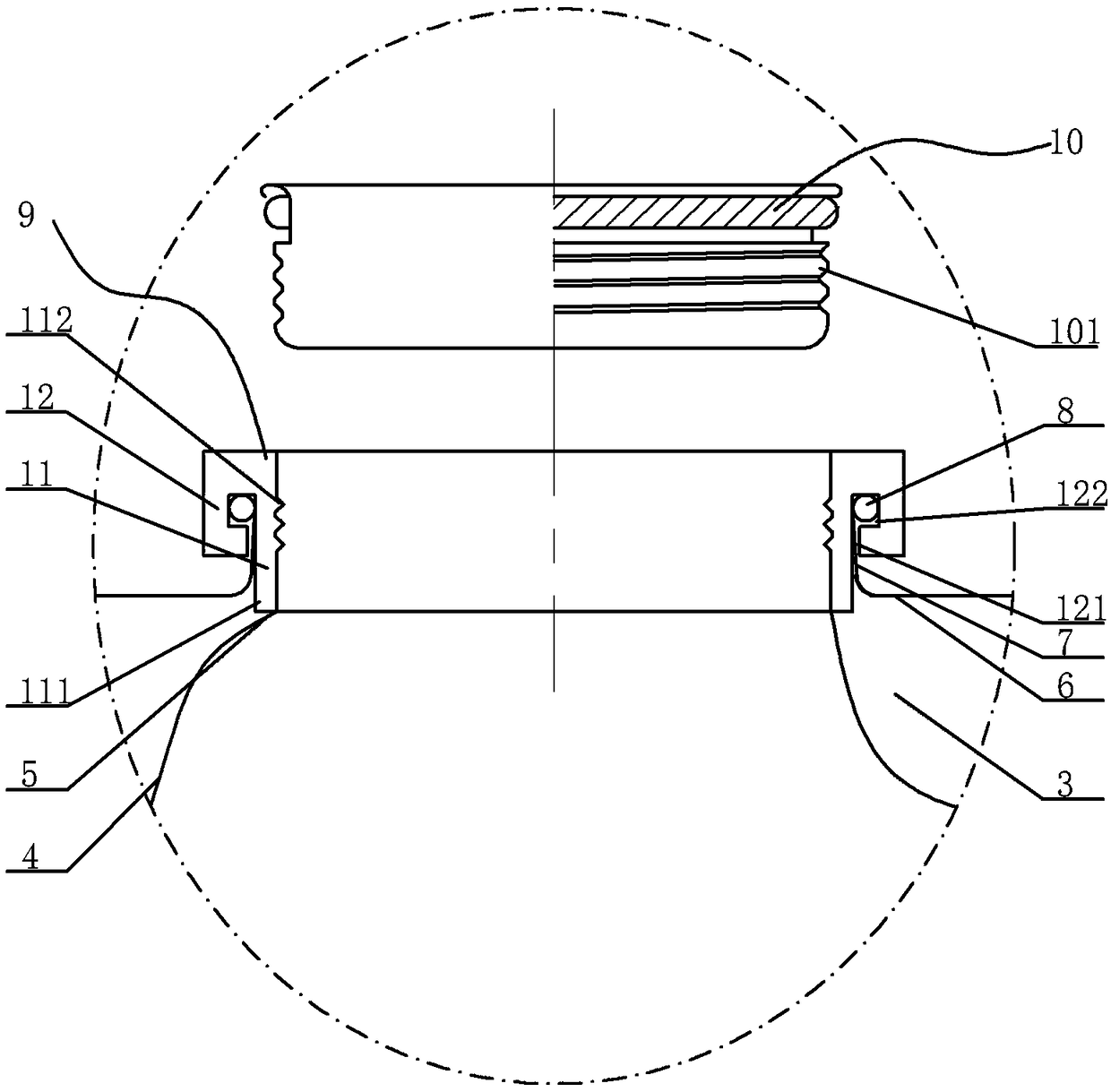

[0024] Specific examples, see figure 1 , the vertical inner ring 11 is provided with a sealing thread groove 112, and the outer ring surface of the plastic cover 10 is provided with a corresponding sealing thread 101, and the plastic cover 10 is sealed and connected to the sealing thread groove 112 through the sealing thread 101; The lower part of the buckle structure 12 is provided with a plugging inlet 121, and the upper part of the plugging inlet 121 is provided with a positioning cavity 122. The side convex roll seal 8 enters into the positioning cavity 122 along the plugging inlet 121 and is fixedly fastened. After the convex roll seal 8, it cannot be opened without being damaged by external force; the plastic mouth seat 9 and the flexible bag 4 are integrally structured, and they need to be replaced as a whole.

[0025] Its working principle is as follows: a flexible bag is arranged in the inner cavity of the metal barrel, which allows the loaded product to enter the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com