Insulation material processing equipment

A technology for processing equipment and thermal insulation materials, which is applied in the field of thermal insulation material processing, can solve the problems of increasing the production cost of thermal insulation materials, increasing the labor intensity of operators, and waste of raw materials and product quality, so as to reduce labor intensity, optimize performance, and improve connection. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Thermal insulation material processing equipment is used to produce thermal insulation materials.

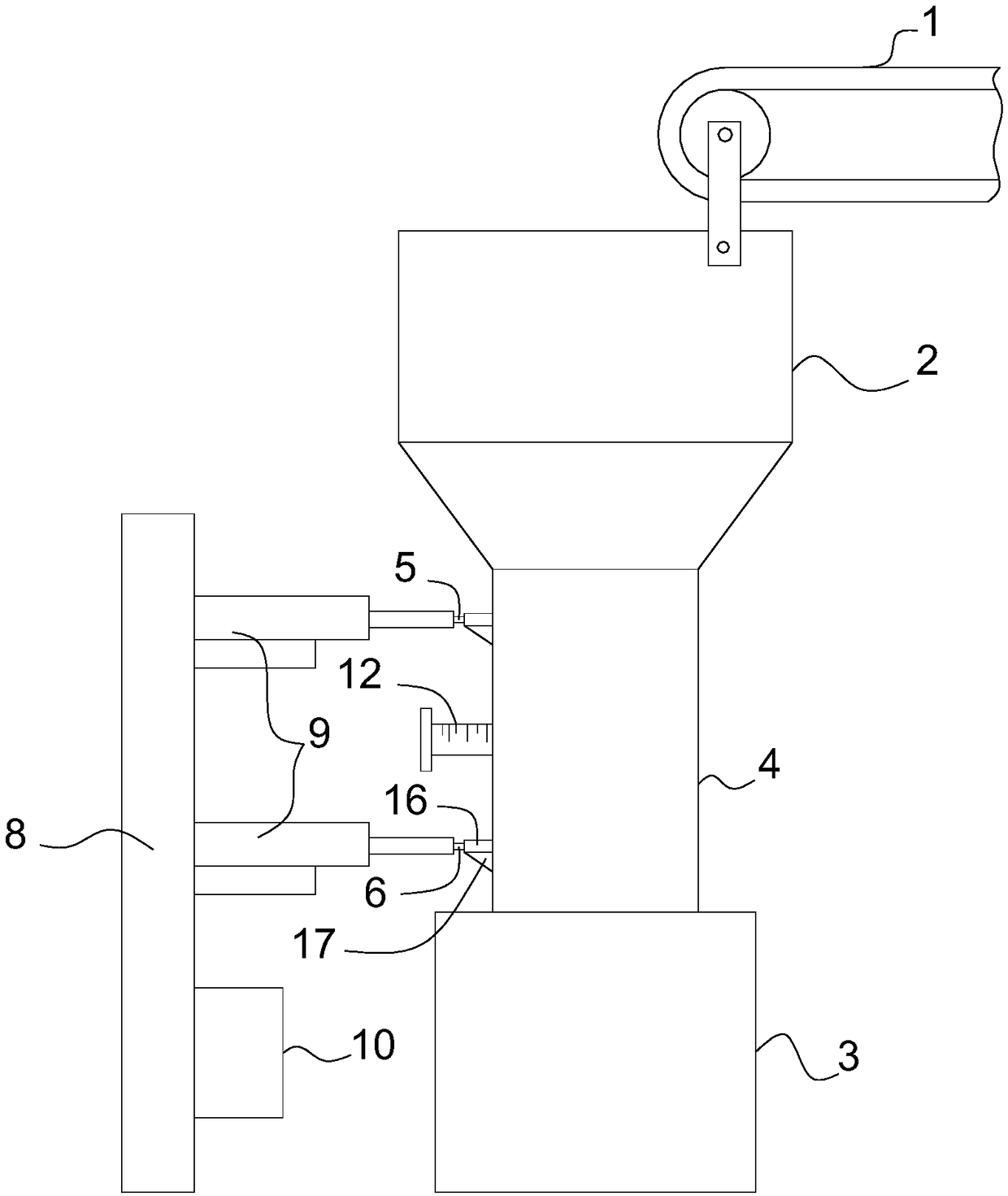

[0029] Such as figure 1 , the thermal insulation material processing equipment includes a conveyor belt 1, a silo 2 and a production box 3, and the conveyor belt 1, the silo 2 and the production box 3 are all conventional structures in the prior art, and will not be described here, and those skilled in the art can easily obtained through purchase.

[0030] The conveyor belt 1 transmits the raw materials to the silo 2 , and a discharge pipe 4 for discharging the raw materials in the silo 2 into the production box 3 is arranged between the silo 2 and the production box 3 .

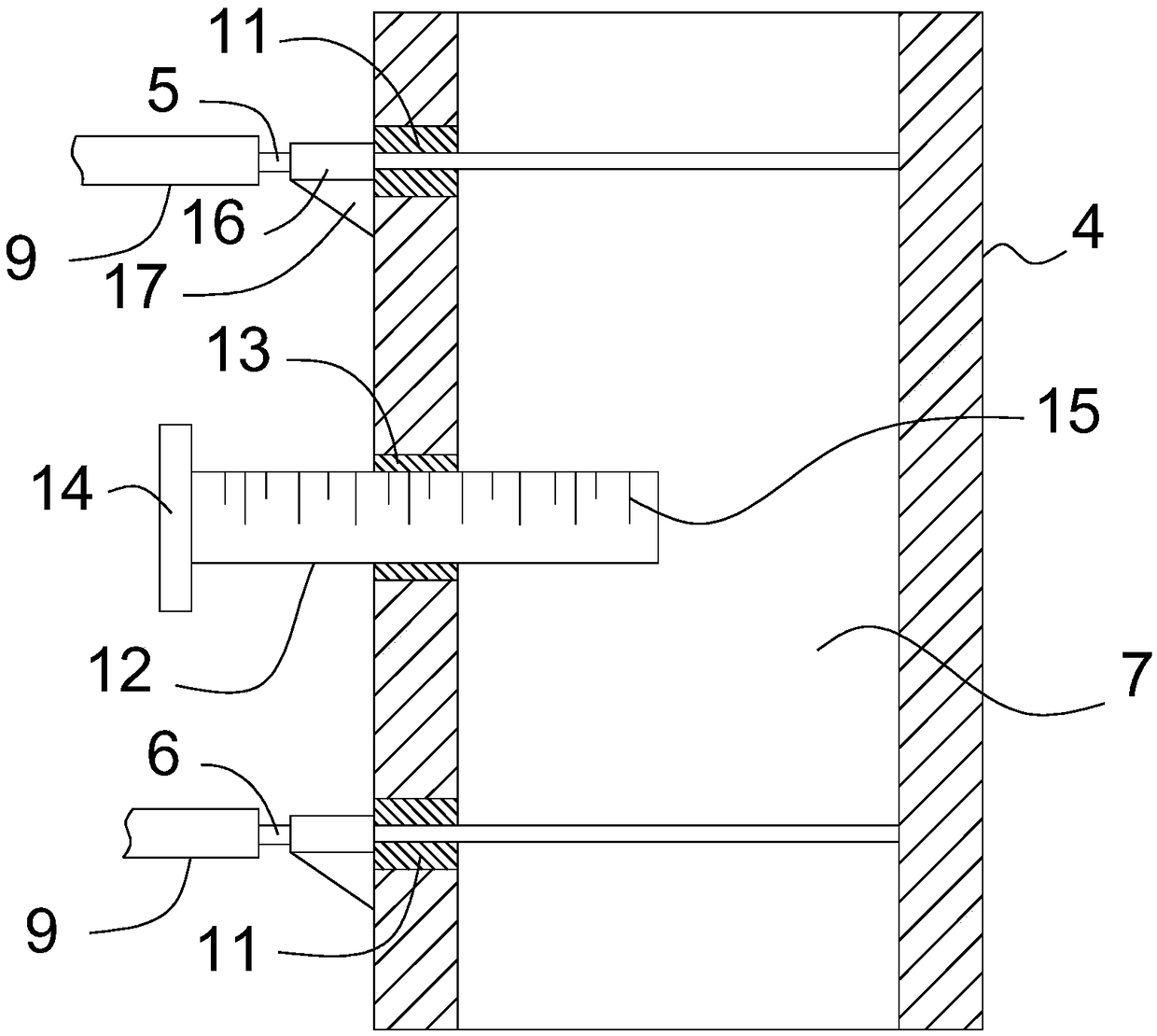

[0031] Such as figure 1 , figure 2 , the cross-sectional shape of the discharge pipe 4 is rectangular, and a quantitative mechanism for controlling the discharge amount of the discharge pipe 4 is arranged in the discharge pipe 4, and the quantitative mechanism includes blocking the discharge pipe T...

Embodiment 2

[0038] This embodiment is an optimization scheme for embodiment 1 in combination with embodiment 1.

[0039] Such as figure 1 , figure 2 , the discharge pipe 4 is also provided with an adjustment column 12 for adjusting the volume of the quantitative space 7, the cross-sectional shape of the adjustment column 12 is circular, and the adjustment column 12 is inserted into the discharge pipe 4, the discharge pipe 4 is provided with a hole that cooperates with the adjustment column 12, the side wall of the hole is bonded with an elastic ring 13, and the adjustment column 12 is provided with a handle 14 , the handle 14 is located outside the quantitative space 7 , and a scale line 15 is provided on the adjustment column 12 . This scale line 15 indicates the volume of the regulating cylinder 12 which is located in the dosing space 7 .

[0040] The handle 14 is covered with a rubber sleeve, and a pattern is arranged on the rubber sleeve, and the scale line 15 is recessed into the...

Embodiment 3

[0043] This embodiment introduces the installation method of the upper sealing plate 5 and the lower sealing plate 6 in combination with the embodiment 1 or the embodiment 2.

[0044] Such as figure 1 , figure 2, on the discharge pipe 4 are respectively provided with guide rods 16 guiding the upper sealing plate 5 and the lower sealing plate 6, there are two pairs of guide rods 16, and the guide rods 16 can be welded on the discharge pipe 4 , the guide rods 16 are respectively provided with guide grooves that cooperate with the upper sealing plate 5 and the lower sealing plate 6, the guide rods 16 are located outside the quantitative space 7, and, in the discharge pipe 4 and the guide rod 16 are provided with support ribs 17 . The supporting rib 17 is welded between the guide rod 16 and the discharge pipe 4 .

[0045] Two cylinders 9 are fixed on the frame 8 by bolts. Two cylinders 9 also can be fixed on the frame 8 by other means.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com