Automatic tape attaching device

A gluing device and automatic technology, applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of easy wrinkling of manual gluing and hard breaking of manual cutting, so as to avoid wrinkling defects and easy cutting , the effect of smooth cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

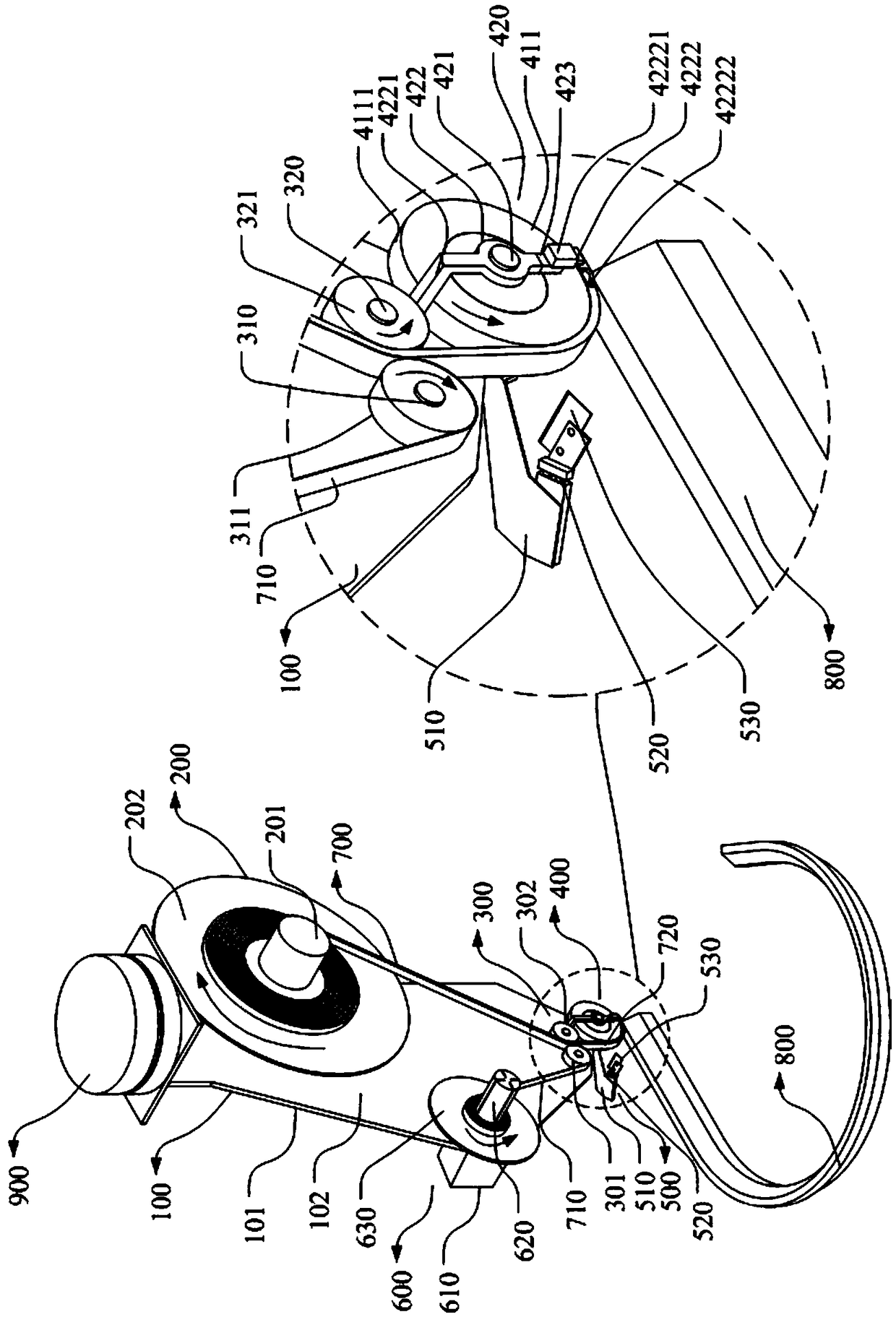

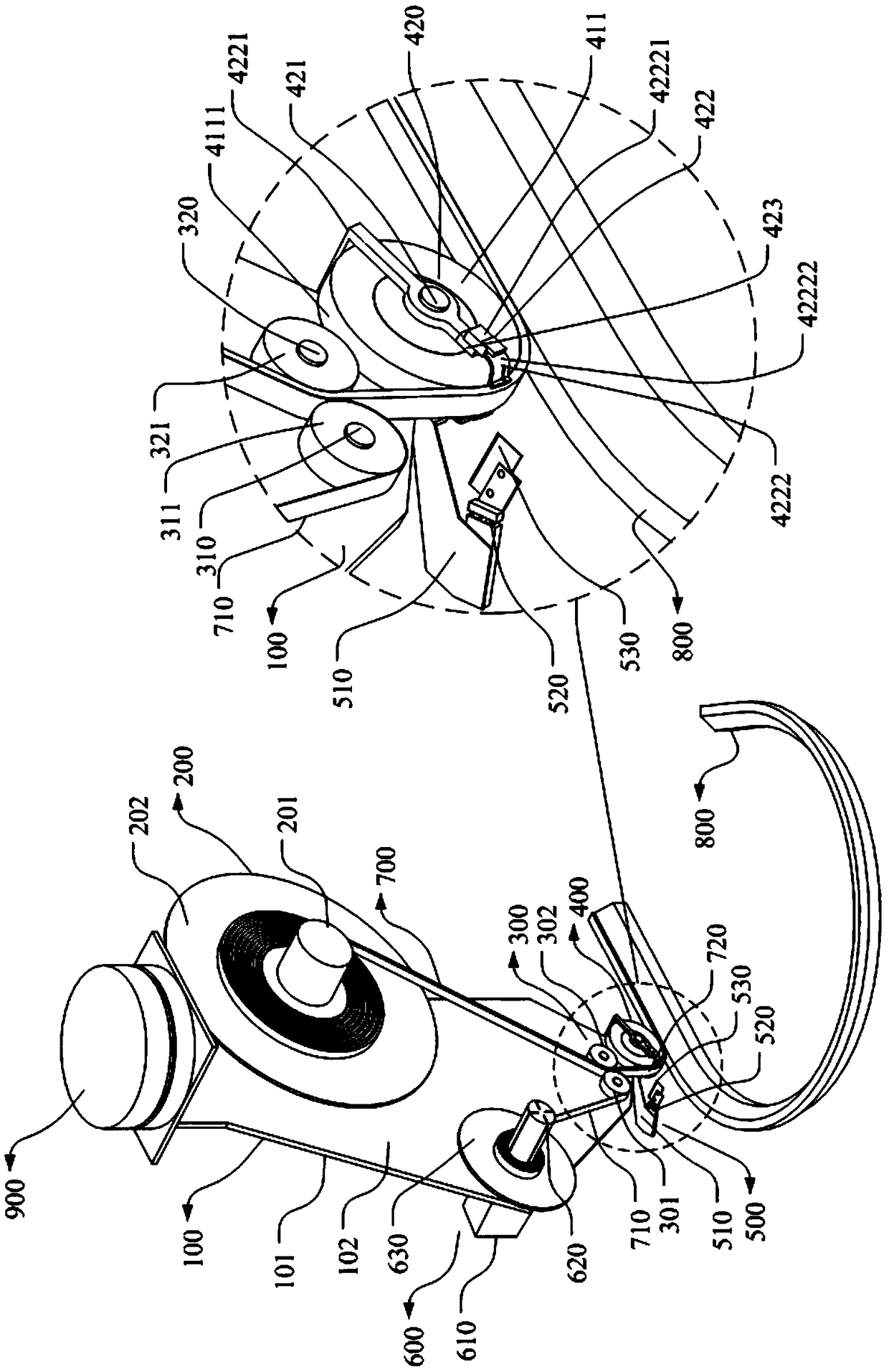

[0053] The present application provides an automatic gluing device for pasting foam glue on a plane of a product to be glued, wherein the foam glue has a release paper and foam adhered to the release paper through an adhesive film. Such as Figure 1-4 As shown, they are three-dimensional structural schematic diagrams of the automatic gluing device in this embodiment when preparing for gluing, during gluing, cutting and finishing gluing. The automatic gluing device of the present application includes a fixed bracket 100 , a feeding mechanism 200 , a separation mechanism 300 , a gluing mechanism 400 , a gluing cutting mechanism 500 and a release paper recycling mechanism 600 . Among them, the fixed bracket 100 is used to support the discharging mechanism 200, the separation mechanism 300, the glue application mechanism 400, the glue cutting mechanism 500 and the release paper recovery mechanism 600, the discharging mechanism 200 is located above the fixed bracket 100, and the se...

Embodiment 2

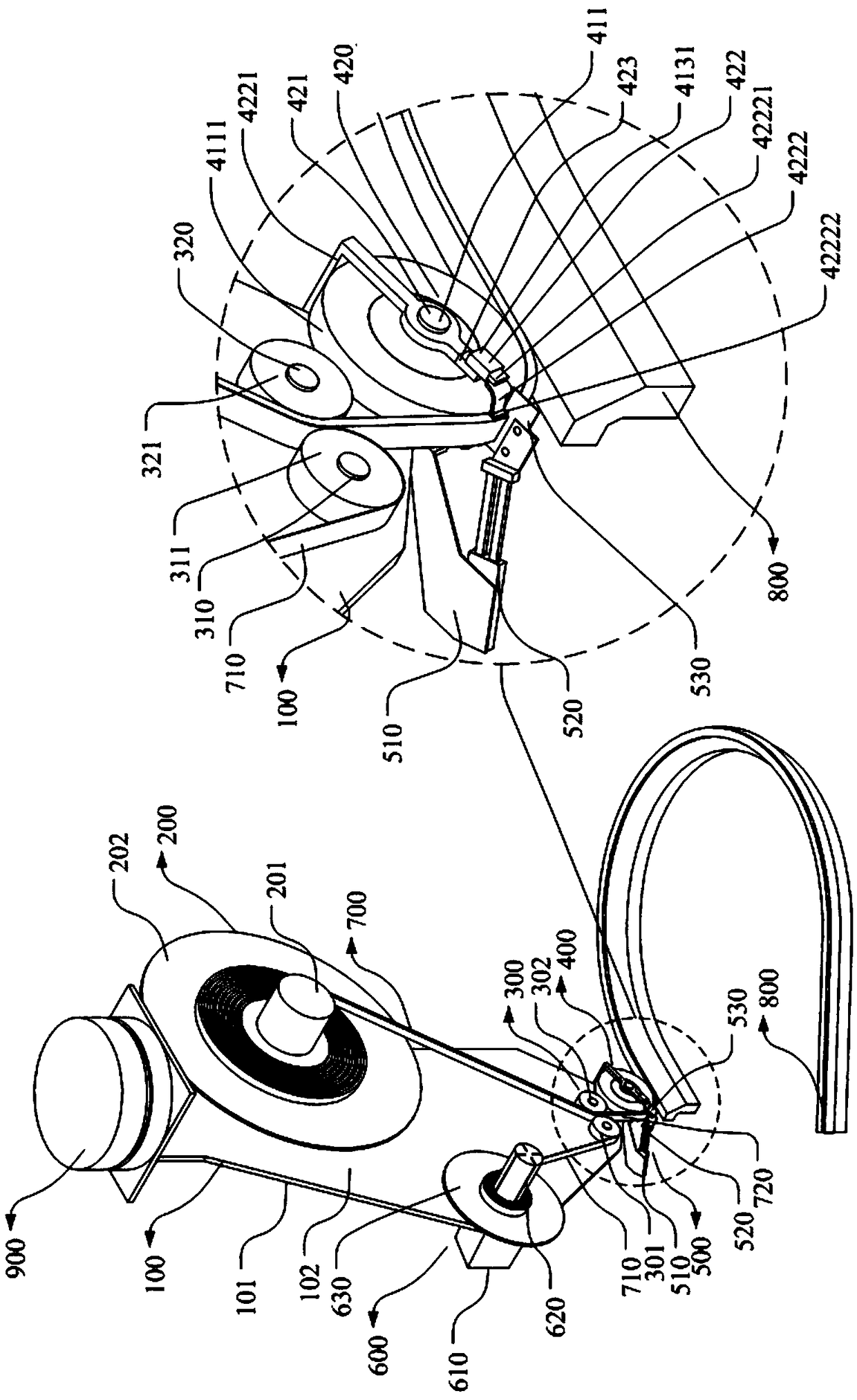

[0064] The difference between this embodiment and the first embodiment lies in that the structure of the gluing mechanism is different, and the structure of the gluing mechanism in this example is simpler than that of the gluing mechanism in the first embodiment. Such as Figure 9-14 As shown, the three-dimensional structure schematic diagram of the automatic gluing device is ready for gluing, gluing process, glue cutting and gluing is completed, and the side view of the gluing mechanism and the gluing cutting mechanism, and the gluing cutting mechanism is fixed on the foam after cutting the foam Schematic diagram of the length of the foam on the wheel surface of the third driving wheel. The gluing mechanism 400 includes a third rotating driving part 410 and a third driving wheel 411; the third rotating driving part 410 is arranged on the second surface 102 of the fixed bracket 100, and the third driving wheel 411 is fixedly sleeved on the third rotating driving part 410 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com