A method for three-dimensional free bending of thin-walled tubes

A thin-walled tube, free technology, used in the field of tube bending and forming, can solve problems such as wrinkling, reduce distortion, reduce production costs, and improve forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments.

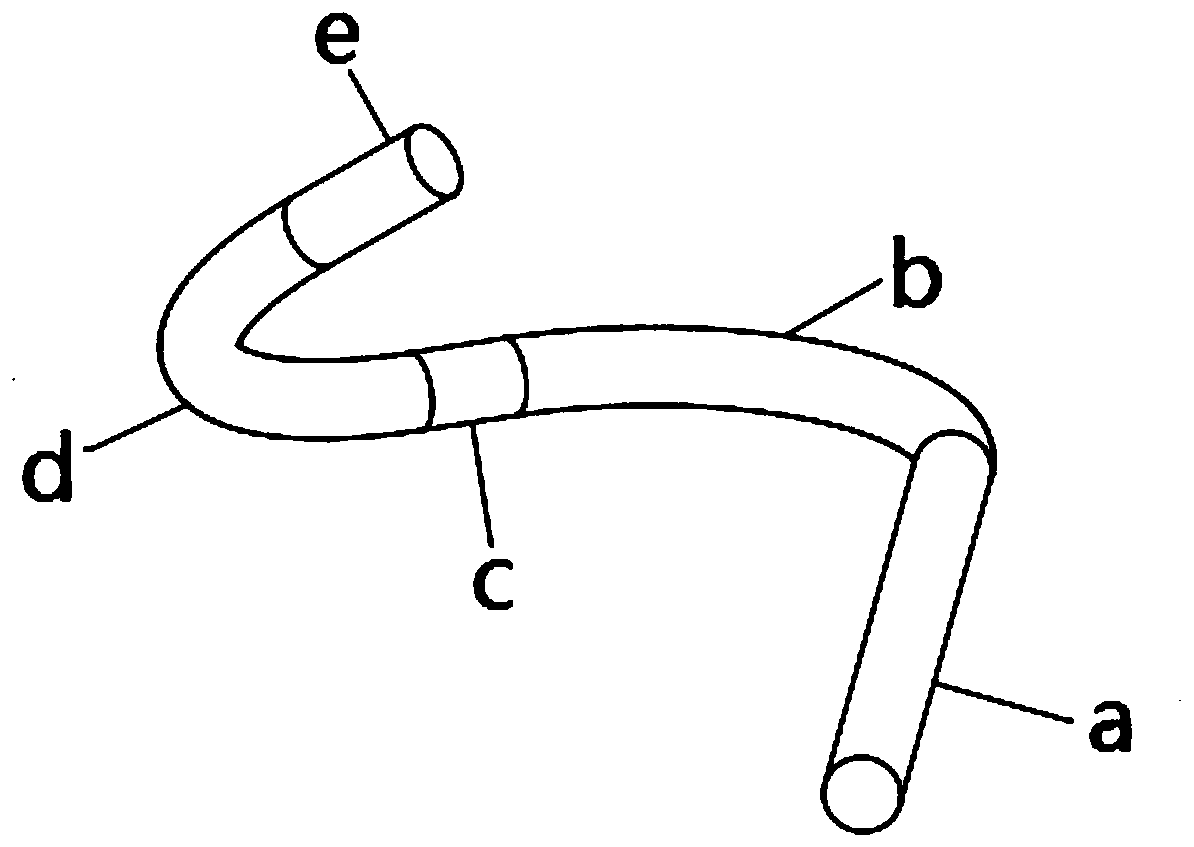

[0019] What this embodiment uses is that diameter is 15mm, the pipe material of wall thickness 2mm, as image 3 shown. This curved pipe has two curved sections and three straight sections: the length of the first straight section a is 400mm; the length of the second straight section c is 40mm; the length of the third straight section e is 65mm; the length of the first curved section b The bending radius is 120mm, the bending angle is 120°, and the bending direction is 0°; the bending radius of the second bending section d is 130mm, the bending angle is 120°, and the bending direction is 40°.

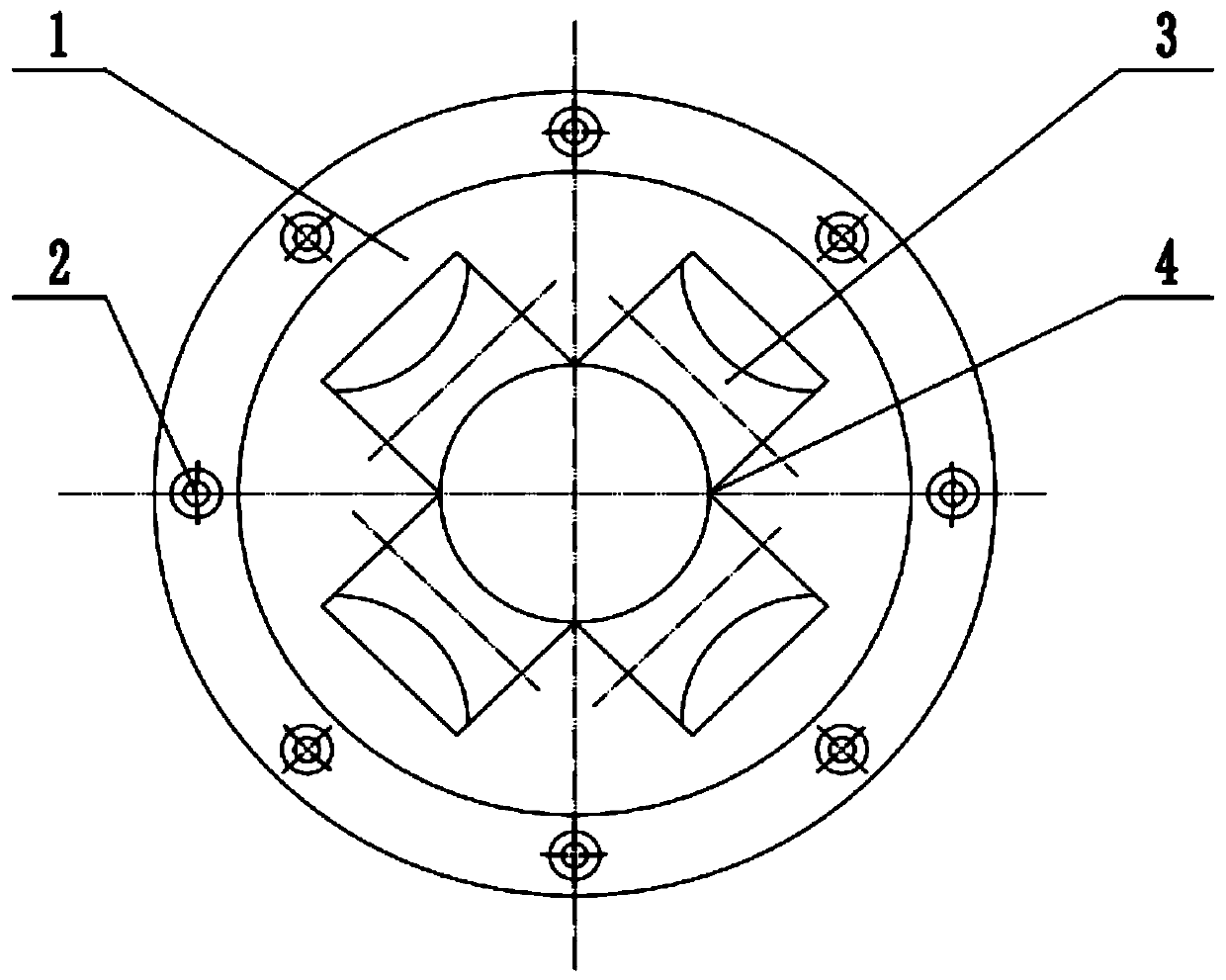

[0020] The multi-roller friction axial feeding and section distortion online correction bending die used in this embodiment is four-roller, specifically including four rolls. The movements of the four rollers are independent, and their friction coefficients and lubrication conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com