A method for overcoming deep-drawing defects of semi-flat tube parts with large aspect ratio

A technology of aspect ratio and parts, which is applied in the field of aircraft manufacturing, can solve problems such as large aspect ratio semi-flat tube molds and sheet material matching accuracy errors, and achieve the goal of avoiding cracking defects, reducing operation difficulty, and reducing workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

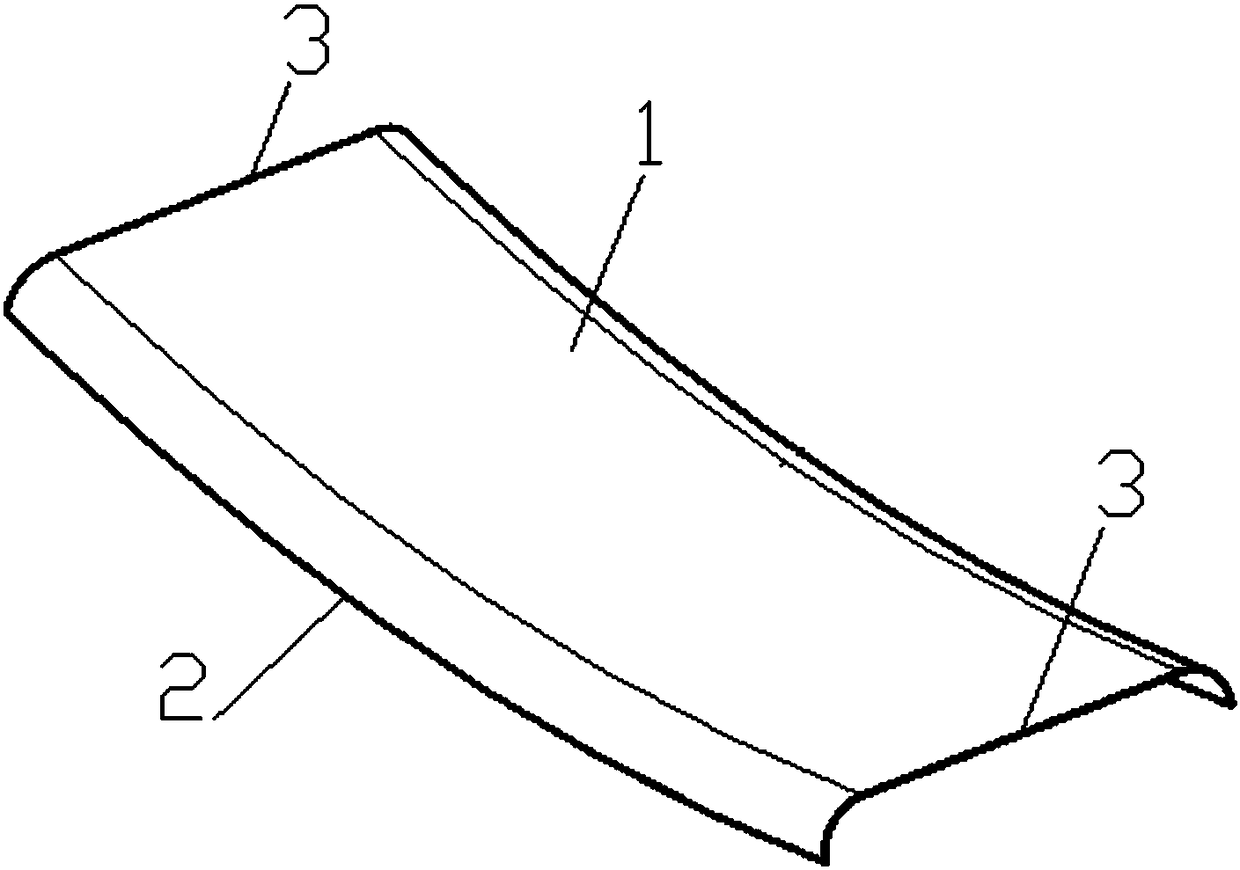

[0015] See attached picture, figure 1 Shown is a theoretical model of a semi-flat tube part to be processed. The theoretical model of the part has an aspect ratio of about 3.2:1 and a length of about 1.5 meters. According to the theoretical model 1, the length ratio of the mold designed to reach 4:1, such a large-scale mold blank-holding area matching accuracy will inevitably have errors, resulting in various fractures and wrinkling defects during sheet metal deep drawing. According to the solution of the present invention, the defects of deep drawing can be effectively overcome. The specific implementation method is as follows:

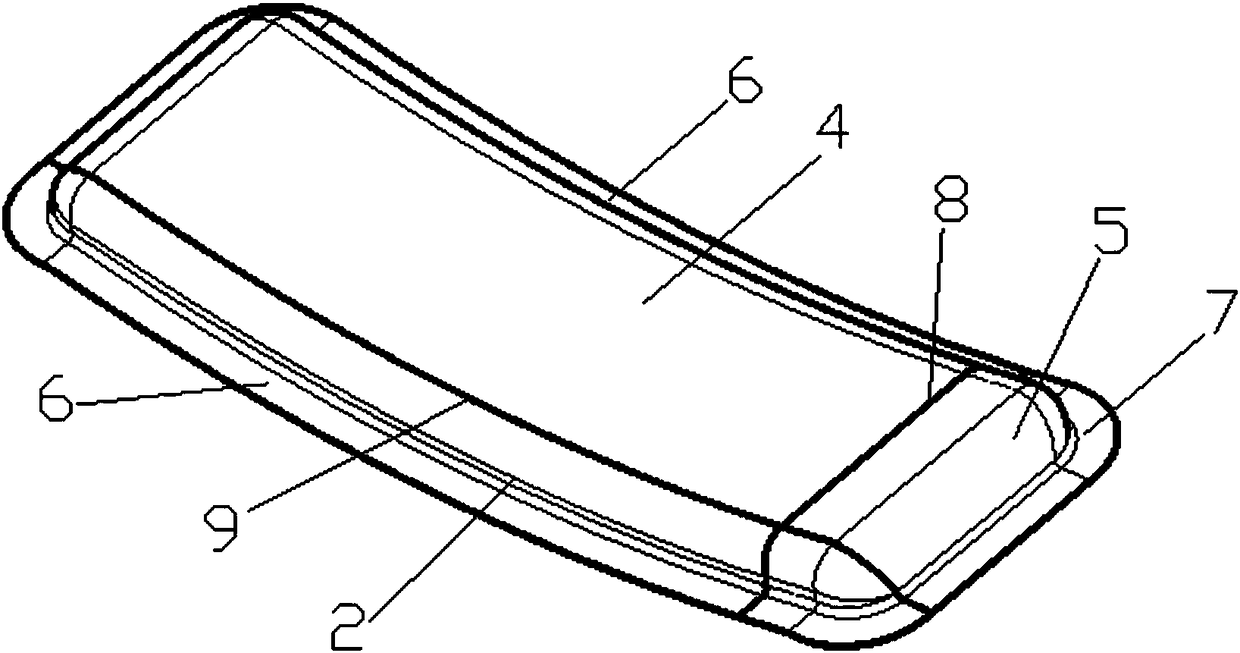

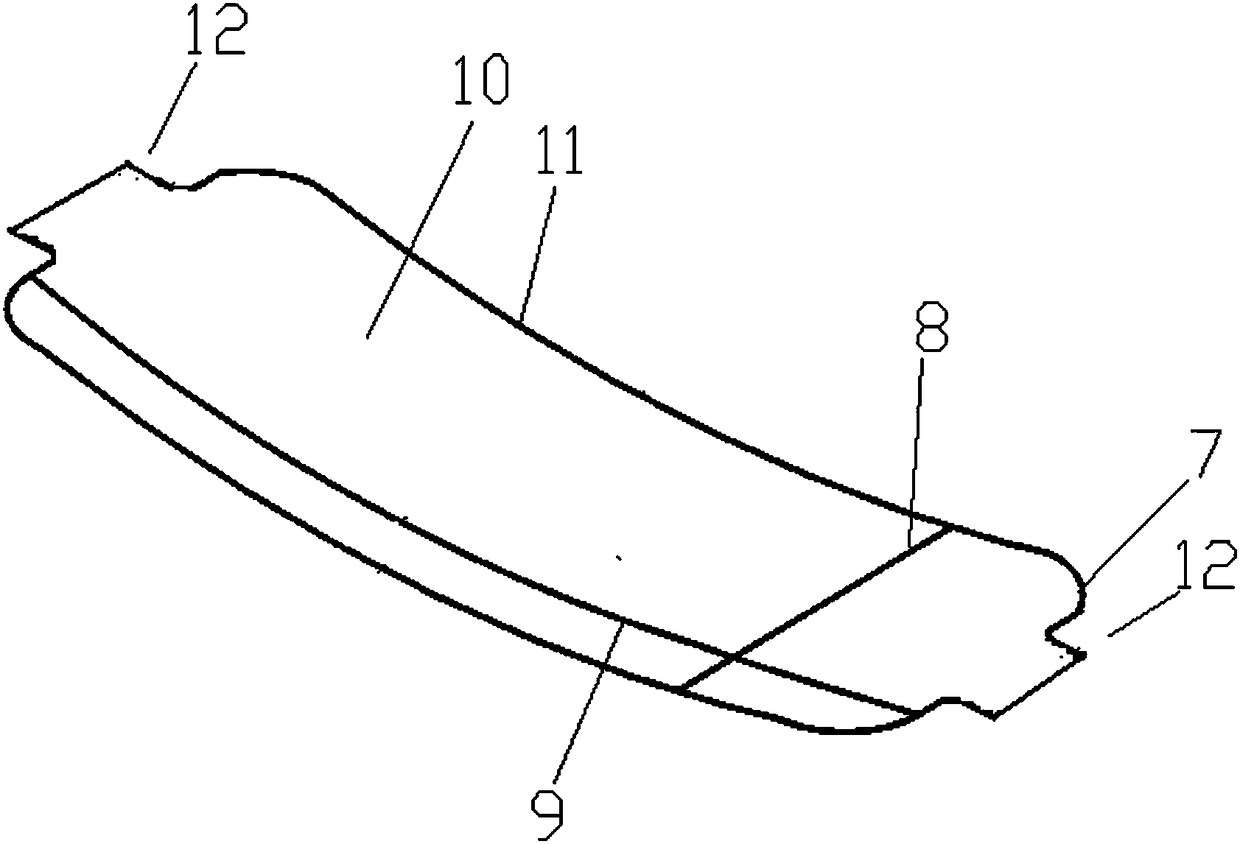

[0016] First, process model 4 is designed according to theoretical model 1, such as figure 2 shown. The process model 4 extends the bending line 2 on both sides of the theoretical model 1 and the boundaries 3 at both ends and performs process compensation to make it a cavity with a filleted process supplementary end 5. The bottom surface of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com