Assembled cooling water pipe convenient for construction of narrow bin surface

A cooling water pipe and assembled technology, which is applied in the direction of hydropower, water conservancy projects, hydropower stations, etc., can solve the problems of increased difficulty of vibration, failure to achieve effectively, damage of cooling water pipes, etc., to improve pouring quality and increase cooling effect, the effect of reducing vibration interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding and implementation of the present invention, the preferred embodiments of the present invention are selected for further description in conjunction with the accompanying drawings.

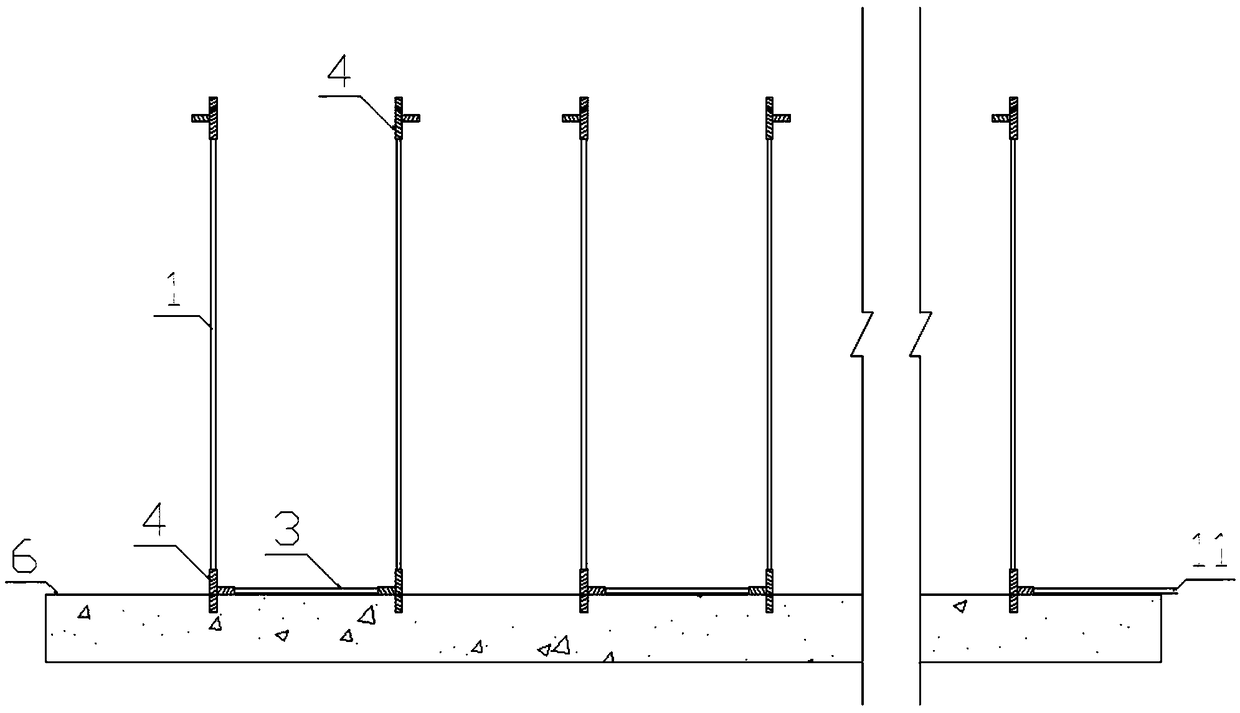

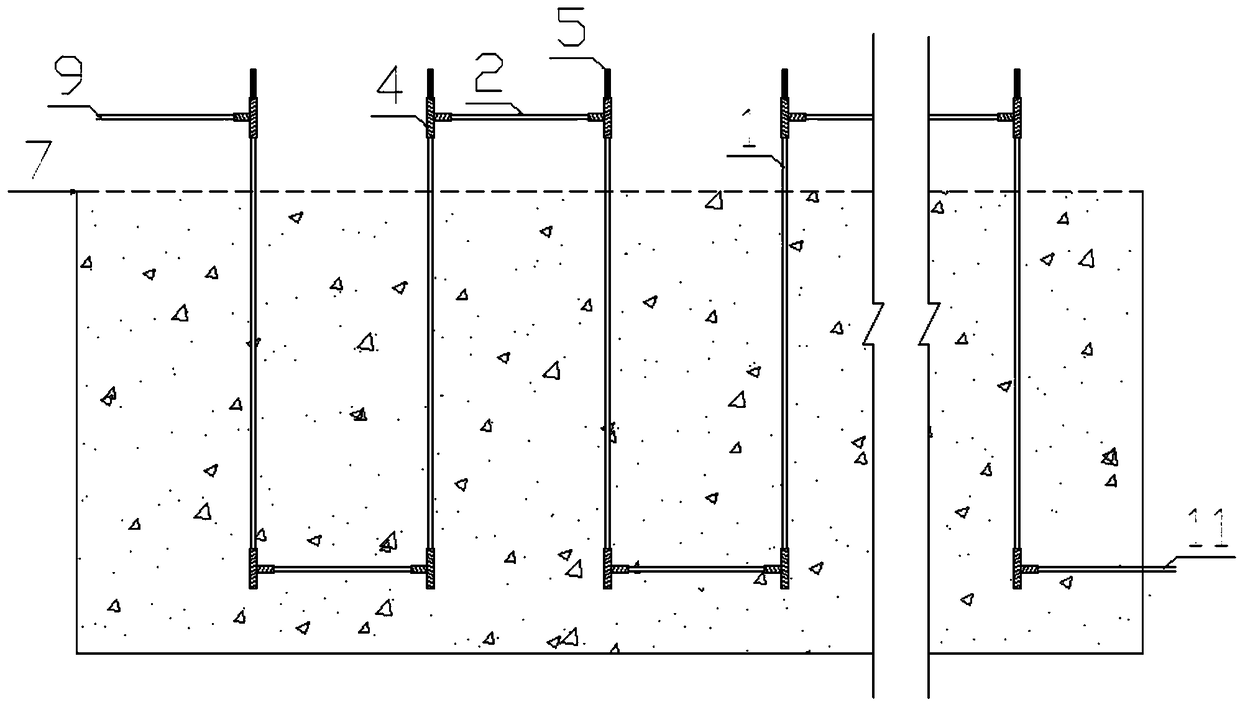

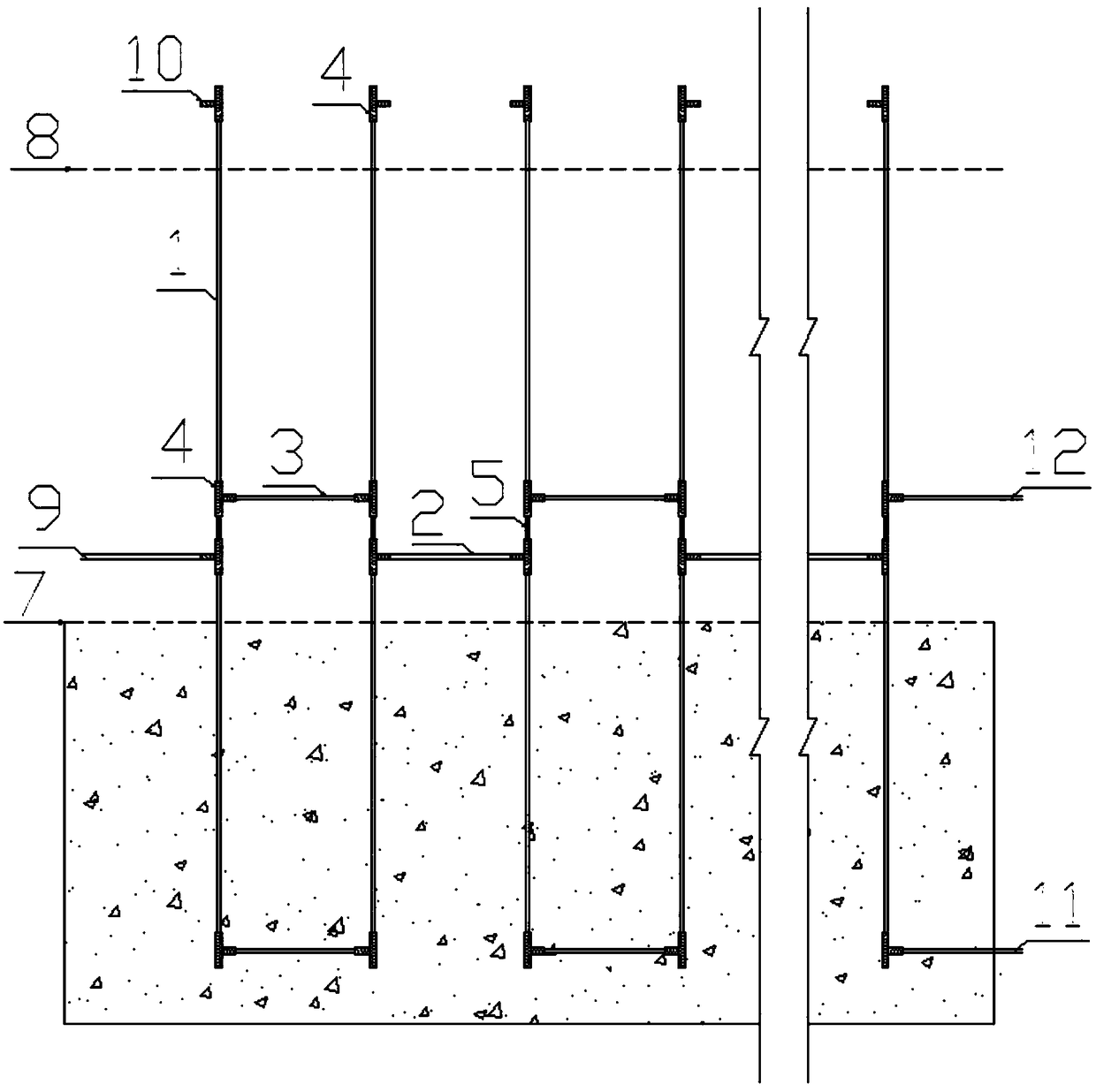

[0023] Such as Figure 1 to Figure 3 As shown, the structure of the present invention includes concrete and cooling water pipes arranged in the concrete. The concrete is a layered structure, and each layer of concrete is arranged with a cooling pipeline. The cooling pipeline includes a vertical pipe 1, an upper horizontal pipe 2 and a lower layer. Horizontal pipe 3; vertical pipe 1 is arranged in parallel, upper horizontal pipe 2 and lower horizontal pipe 3 are arranged alternately, one end of vertical pipe 1 is connected to upper horizontal pipe 2, and the other end is connected to lower horizontal pipe 3 to form a serpentine pipeline; The pipe 2 is located above the top surface of the concrete of the layer in which it is located.

[0024] For ease ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com