Variable-cross-section aluminum alloy formwork construction method

A technology of aluminum alloy formwork and construction method, which is applied in the connection parts of formwork/formwork/work frame, formwork/formwork member, building structure, etc., can solve the problems of low turnover rate and comprehensive benefit of aluminum formwork construction , to maximize the benefits of quality control, ensure reliability and stability, and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] Embodiment: A construction method of aluminum alloy template with variable cross-section structure, including the following steps:

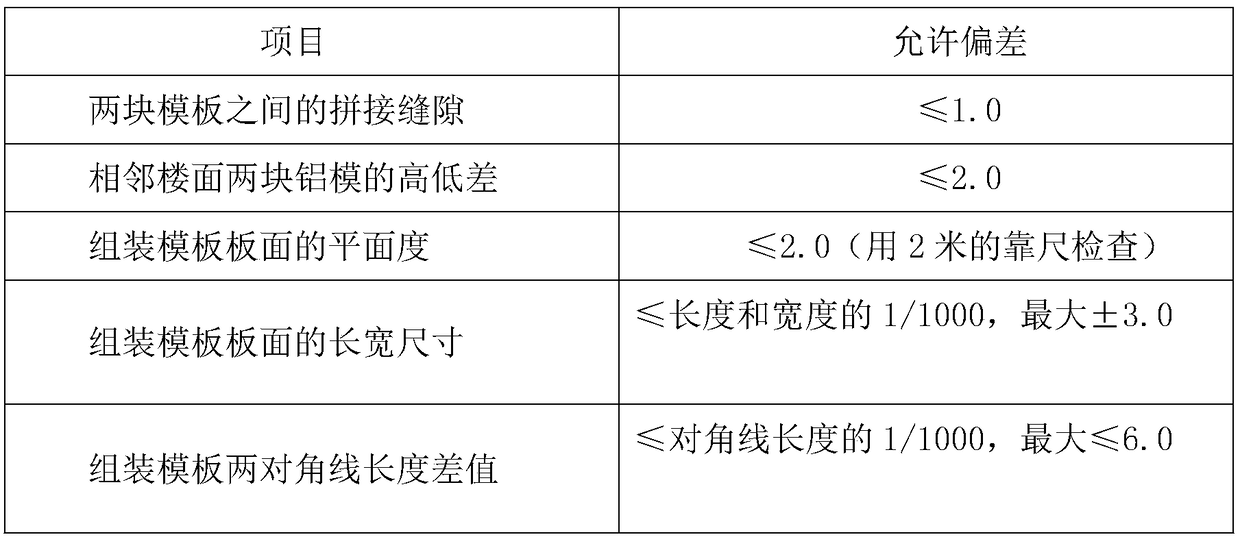

[0022] (1) Aluminum mold design: According to the structural drawings of the office building, carry out structural analysis. According to the characteristics of the office building with many changes in floors and variable cross-sections, it mainly analyzes and plans the structure type, structural variable cross-section situation, and special-shaped structure distribution. In particular, it is necessary to focus on the analysis of the position and distribution of variable cross-sections such as frame columns, shear walls, and frame beams, because the above variable cross-sections will have a greater impact on the mold matching work; for the special-shaped structure of office buildings, more in-depth deepening is required Design, this work will have a greater impact on the quantity of aluminum mold matching, so overall consideration and improvem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com