Method for mining coal through cooperation of crack filling and remained coal seam in uplink re-mining tool post remnant mining region

A coal mining method and a technology for residual mining areas, which are applied in the field of coal mining, can solve the problems of instability and damage of knife pillar coal pillars, unfavorable upward mining, etc., and achieve the effects of saving time, saving filling cost, and improving safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are part of the embodiments of the present invention, rather than All the embodiments; based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative work all belong to the protection scope of the present invention.

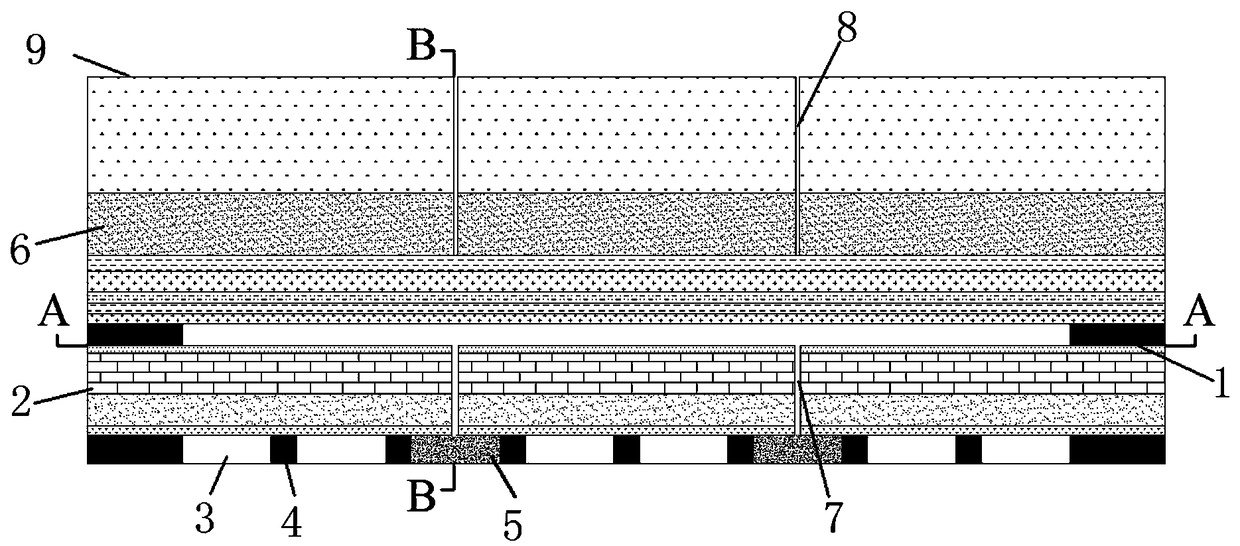

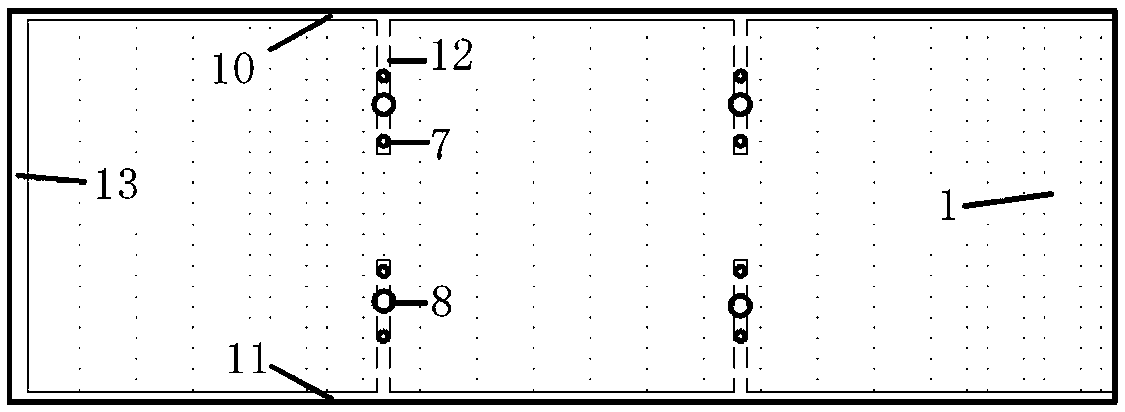

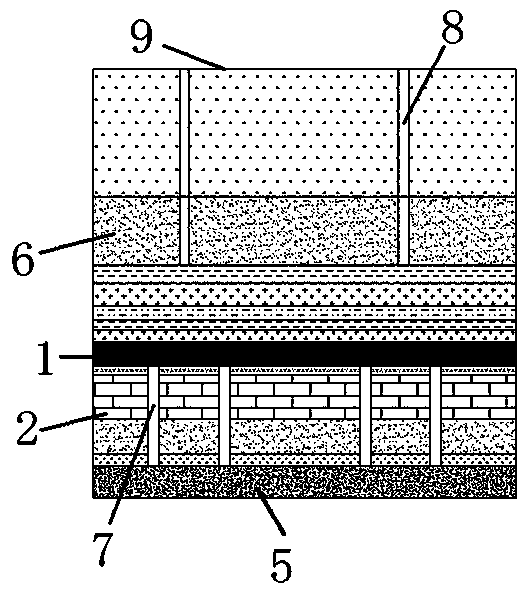

[0023] The present invention proposes a coal mining method combining crack filling and upward re-extraction of the remaining coal seam in the residual mining area of the cutter column. Under the condition of ensuring that the upward mining in the residual mining area of the cutter column does not break the lower interlayer rock strata The empty area is fully filled to enhance the bearing capacity of the cutter co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com