Pre-drying heating device for rotary screen printing machine

A technology of heating device and printing machine, applied in heating device, lighting and heating equipment, drying and other directions, can solve the problems of low production efficiency, poor drying efficiency, slow drying speed, etc., to improve production efficiency and product quality , Improve product quality, good drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0020] Example.

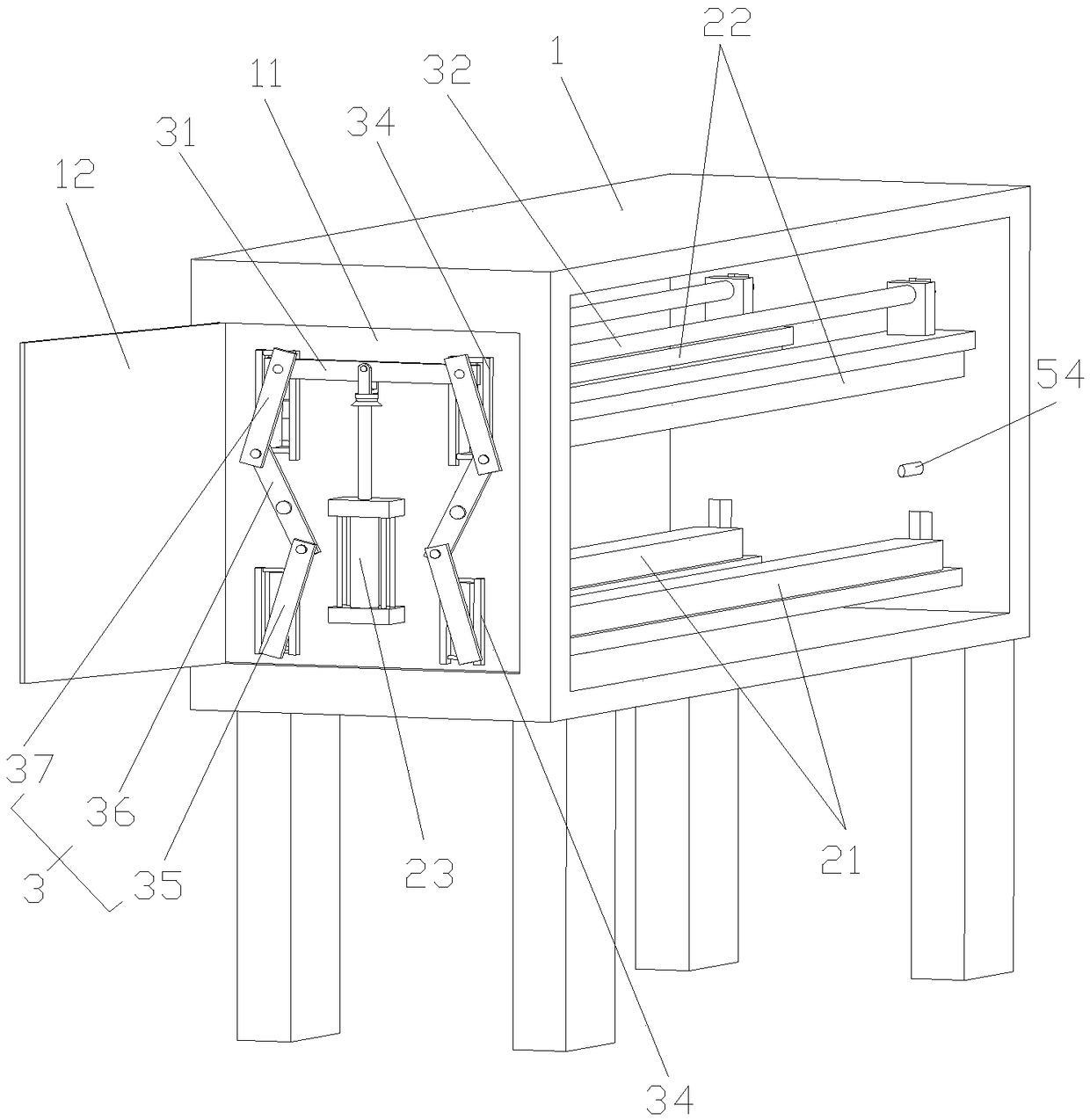

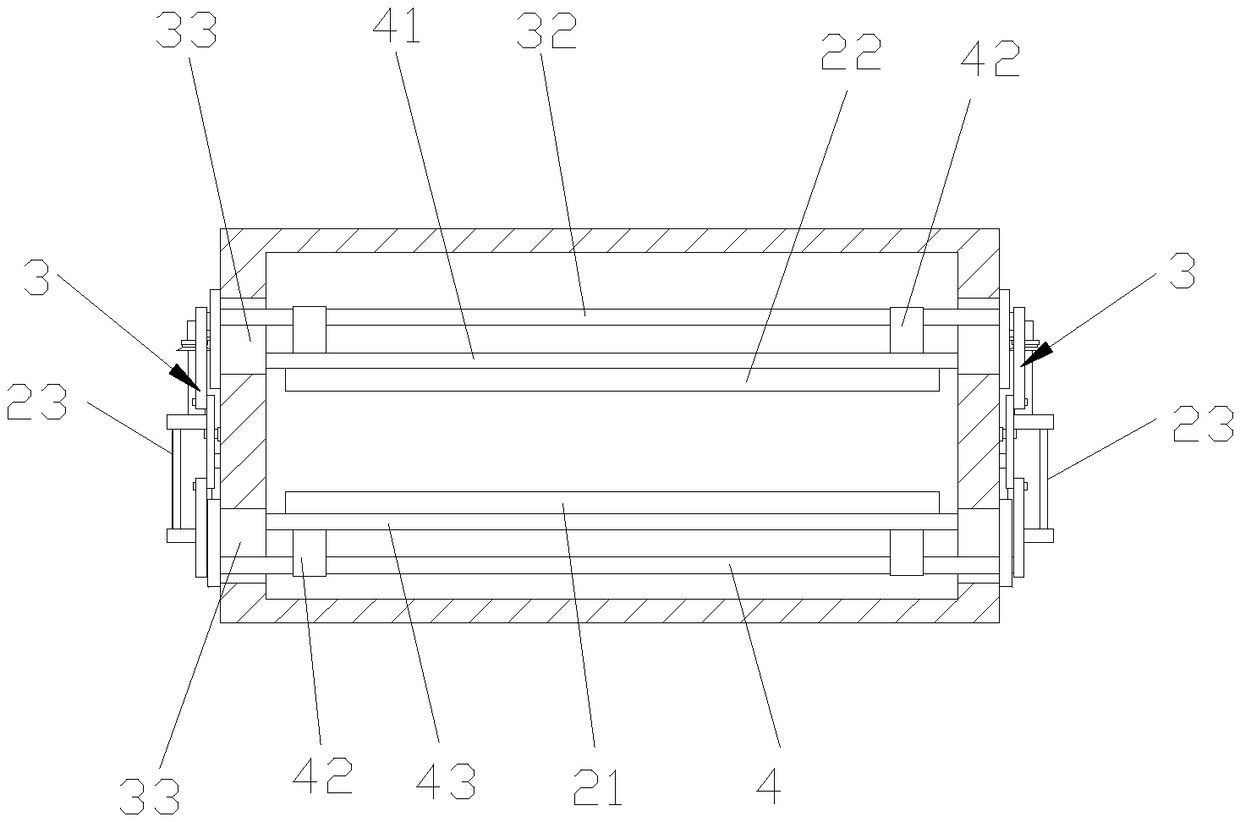

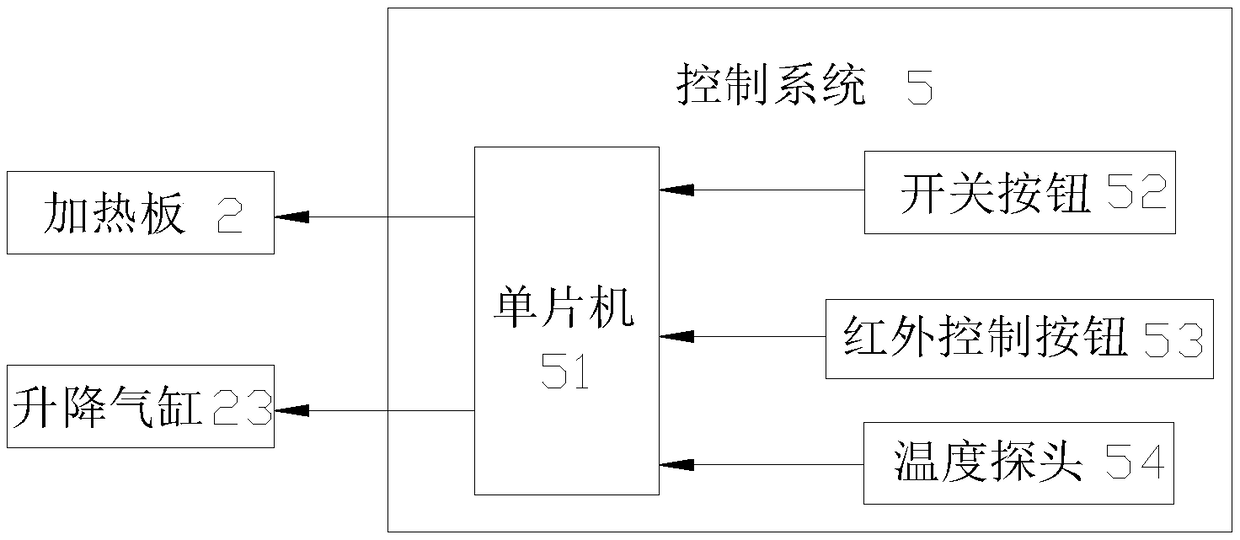

[0021] like Figure 1-3 As shown, the pre-baking heating device of the rotary screen printing machine includes a frame 1, both ends of the frame 1 are open, and the interior of the frame 1 is provided with two sets of heating plates 2 distributed side by side along the length direction of the frame 1. , each group of heating plates 2 includes a bottom heating plate 21 and a top heating plate 22 distributed in parallel up and down; the two outer sides of the frame 1 are provided with lifting cylinders 23, and the two sides of the lifting cylinder 23 are provided with a pair of mutually symmetrical lifting racks 3. The bottom end of the lifting frame 3 is connected to the bottom heating plate 21 through the bottom lifting shaft 4. Between the top ends of the two lifting frames 3 is a lifting rod 31 connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com