An online evaluation method for flash welding quality of anchor chain based on dtw and mds

A flash welding and high-quality technology, applied in welding equipment, resistance welding equipment, character and pattern recognition, etc., can solve the problems of long calculation time, high computer performance requirements, not suitable for industrial sites, etc., to reduce production costs and improve production. Efficiency and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

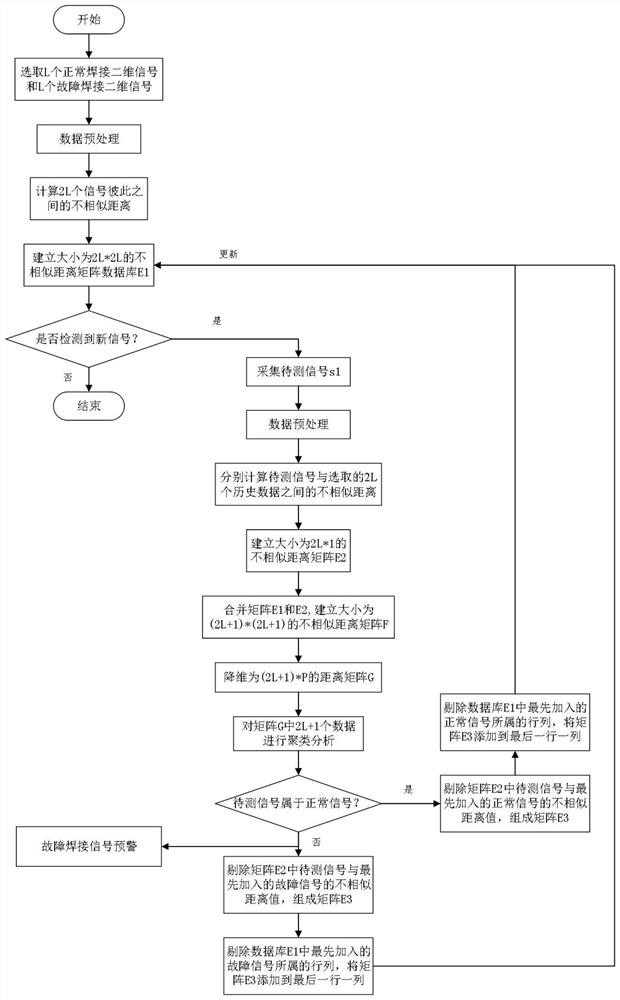

[0070] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0071] A kind of anchor chain flash welding quality online evaluation method based on DTW and MDS of the present invention comprises the following steps:

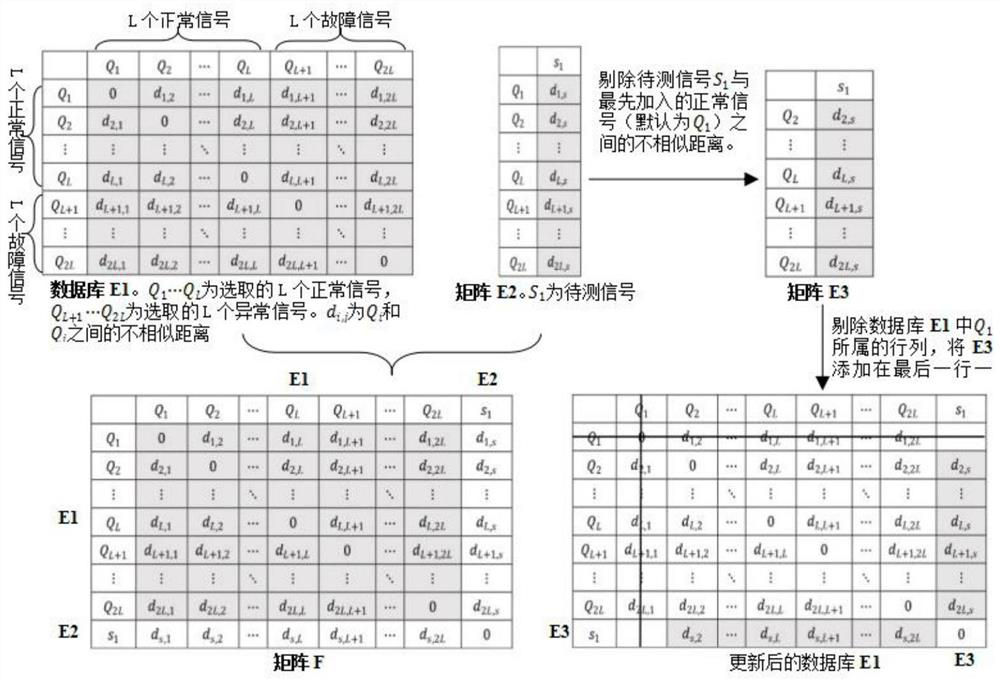

[0072] Step 1) Establish database E1

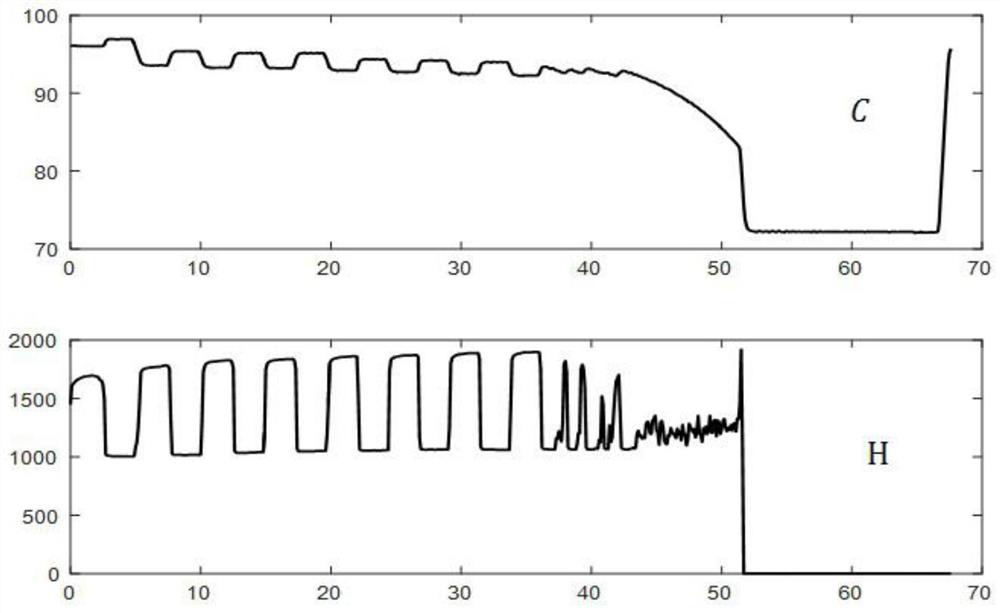

[0073] Step 1.1) Select L normal welding signals Q from historical welding record data according to actual welding experience 1 , Q 2 ,...,Q L and L fault welding signals Q L+1 , Q L+2 ,...,Q 2L (The selected 2L signals are two-dimensional signals composed of electrode position signals and current signals, such as Q 1 =[A B], A=[a 1 , a 2 ,...,a i ,...,a n ] T is the electrode position signal, B=[b 1 , b 2 ,...,b i ,...,b n ] T for the current signal).

[0074] Step 1.2) Data preprocessing. According to the z-score algorithm, the electrode position and current two-dimensional signal Q 1 For normalization:

[0075]

[0076]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com