Storage grillage for spent fuel assembly

A technology for storing grids and spent fuel, which is applied in the field of nuclear engineering equipment, can solve the problems of lowering the Keff value and not satisfying the storage requirements, and achieves the effect of lowering the Keff value and better positioning the storage tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

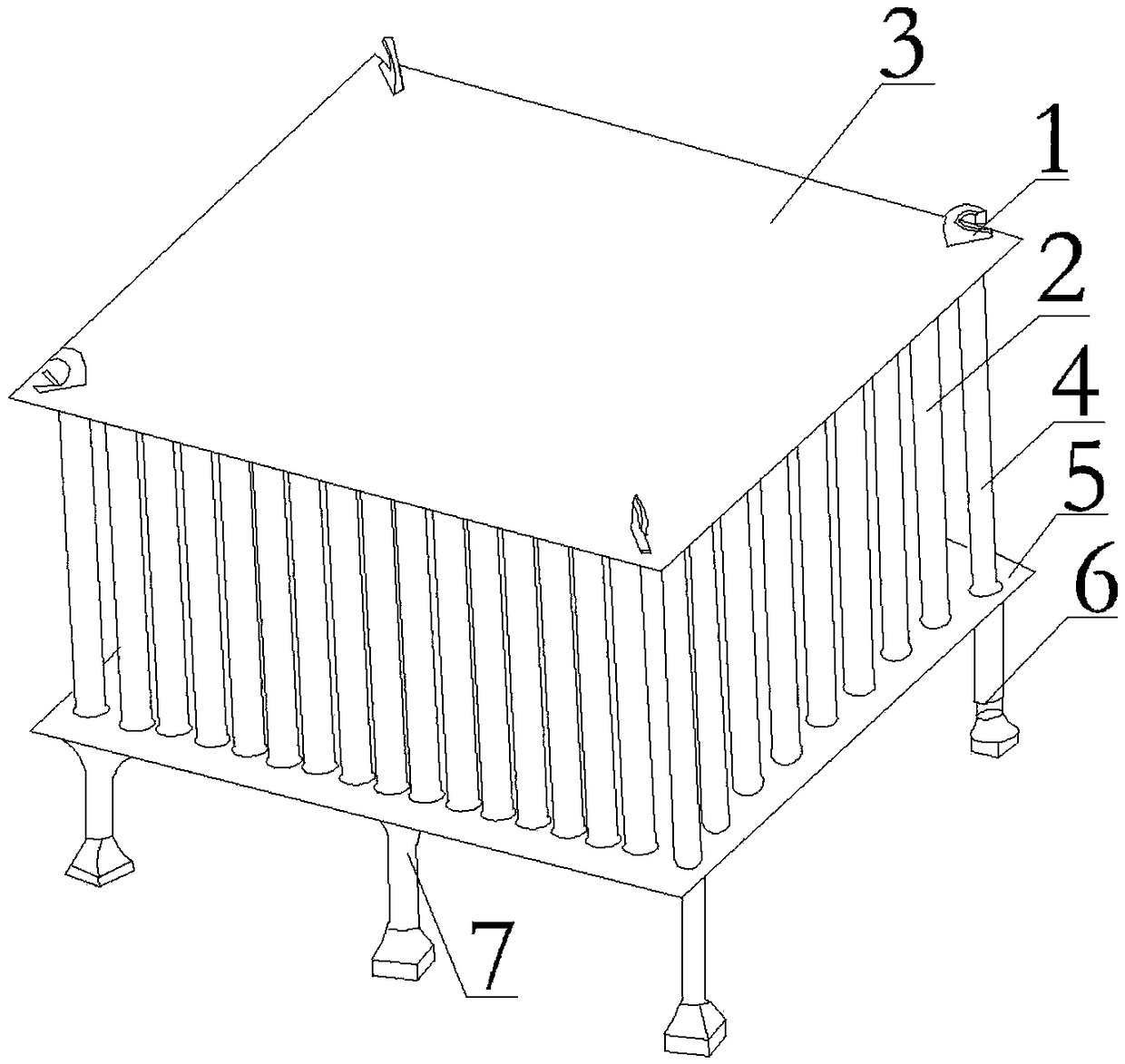

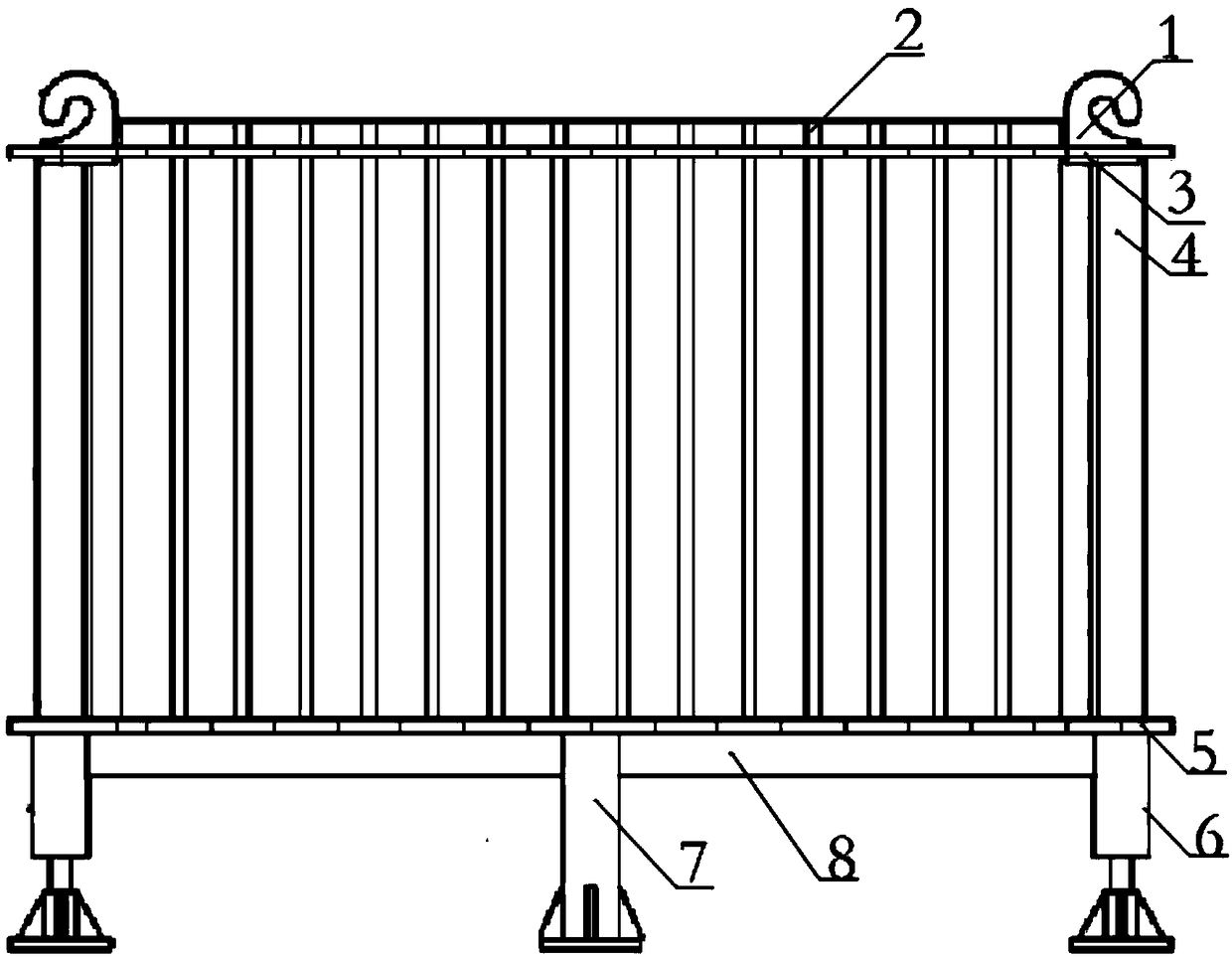

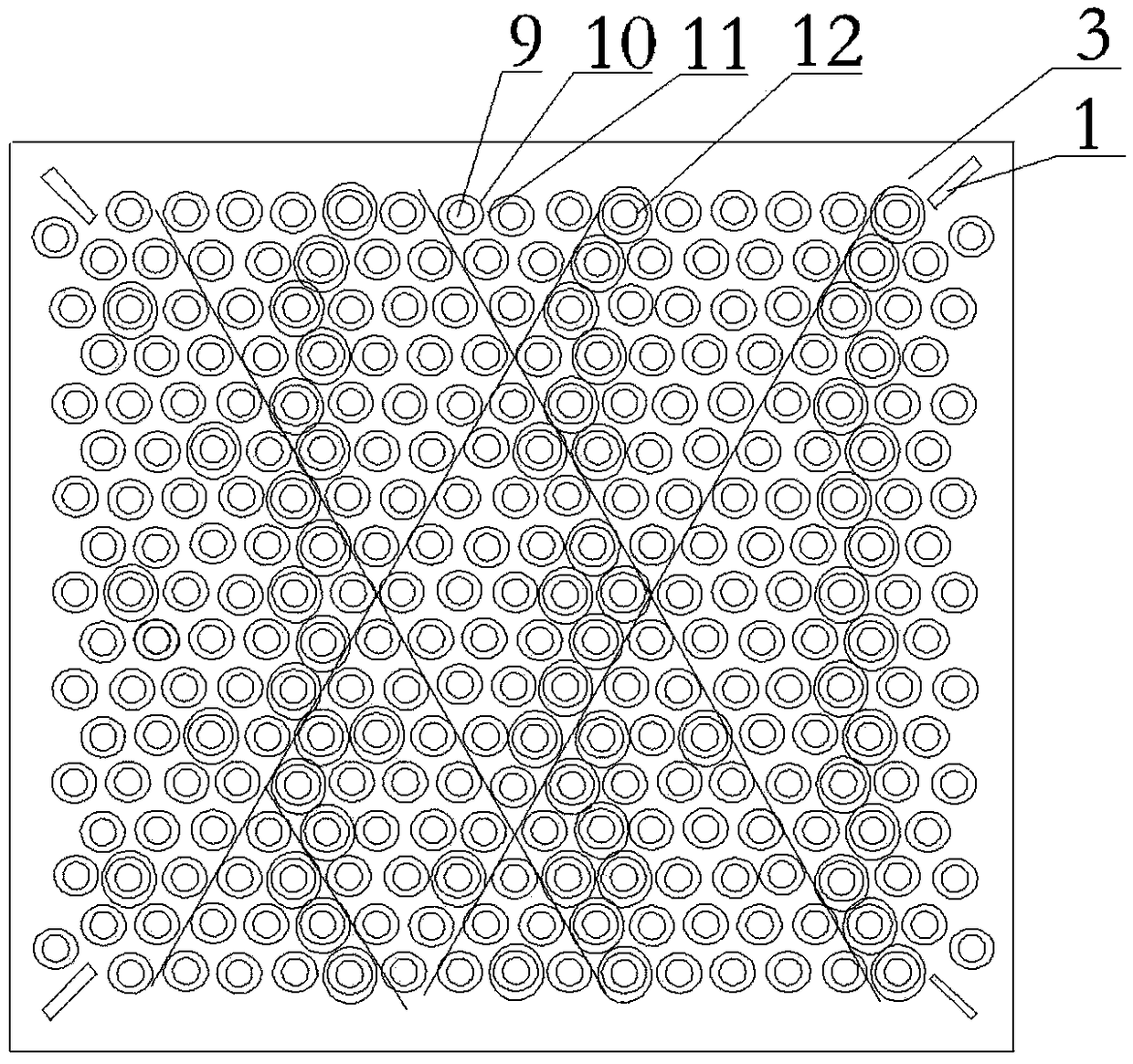

[0026] Such as figure 1 — Figure 4 As shown, a spent fuel assembly storage grid includes an upper supporting plate 3 and a lower supporting plate 5, and the upper supporting plate 3 and the lower supporting plate 5 are distributed in parallel up and down; the upper supporting plate 3 is provided with a storage tube 2, a hexagonal Shaped storage tube 9, one end of storage tube 2, hexagonal storage tube 9 is connected with supporting plate 3, and the other end of storage tube 2, hexagonal storage tube 9 is all connected with lower supporting plate 5; Storage tube 2, The hexagonal storage tubes 9 are all hollow tubes and are used to store spent fuel assemblies. The number of storage tubes 2 is greater than that of the hexagonal storage tubes 9, and the storage tubes 2 are evenly distributed around the hexagonal storage tube 9. Around, reduce the subcriticality of the whole storage system.

[0027] Wherein, the storage units formed by the storage tubes 2 and the hexagonal stora...

Embodiment 2

[0034] This embodiment is further limited on the basis of Embodiment 1. The upper supporting plate 3 and the lower supporting plate 5 have the same structure, the upper supporting plate 3 is a support plate structure with a quadrilateral cross section, and the four corners of the upper supporting plate 3 are provided with Lug 1. The effect of lifting lug 1 is to be convenient to hoisting the installed storage grid into underwater storage.

Embodiment 3

[0036] The difference between this embodiment and the above embodiment is that: the four legs of the lower supporting plate 5 are provided with adjustable legs 6 , and the non-adjustable legs 7 are arranged between the two adjustable legs 6 . The weight of the whole storage grid will all act on the supporting legs, so the position of the maximum load-bearing of the supporting legs, in order to keep the fuel storage grid leveling in the storage pool, wherein, the four feet of the lower supporting plate 5 can The legs 6 are adjusted, and the two non-adjustable legs 7 between the two adjustable legs 6 are used as fulcrums. By adjusting the length of the adjustable legs 6, the purpose of adjusting the balance of the storage grid is finally achieved.

[0037] Wherein, the adjustment structure of the adjustable leg is composed of a strut nut and a stud, and the strut nut and the stud are threaded to form a spiral pair, and the rotation of the stud drives the up and down movement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com